Preparation method of composite layer non-woven fabric

A technology of non-woven fabrics and composite layers, which is applied in the field of preparation of composite layer non-woven fabrics, and can solve the problems of insufficient bonding of adsorbent filter powder and intermediate spinneret cotton, layering, and inability to reflect the adsorption performance of filter cloth adsorbent particles. , to achieve uniform filtration effect, enhanced dispersion effect, and strong lateral penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

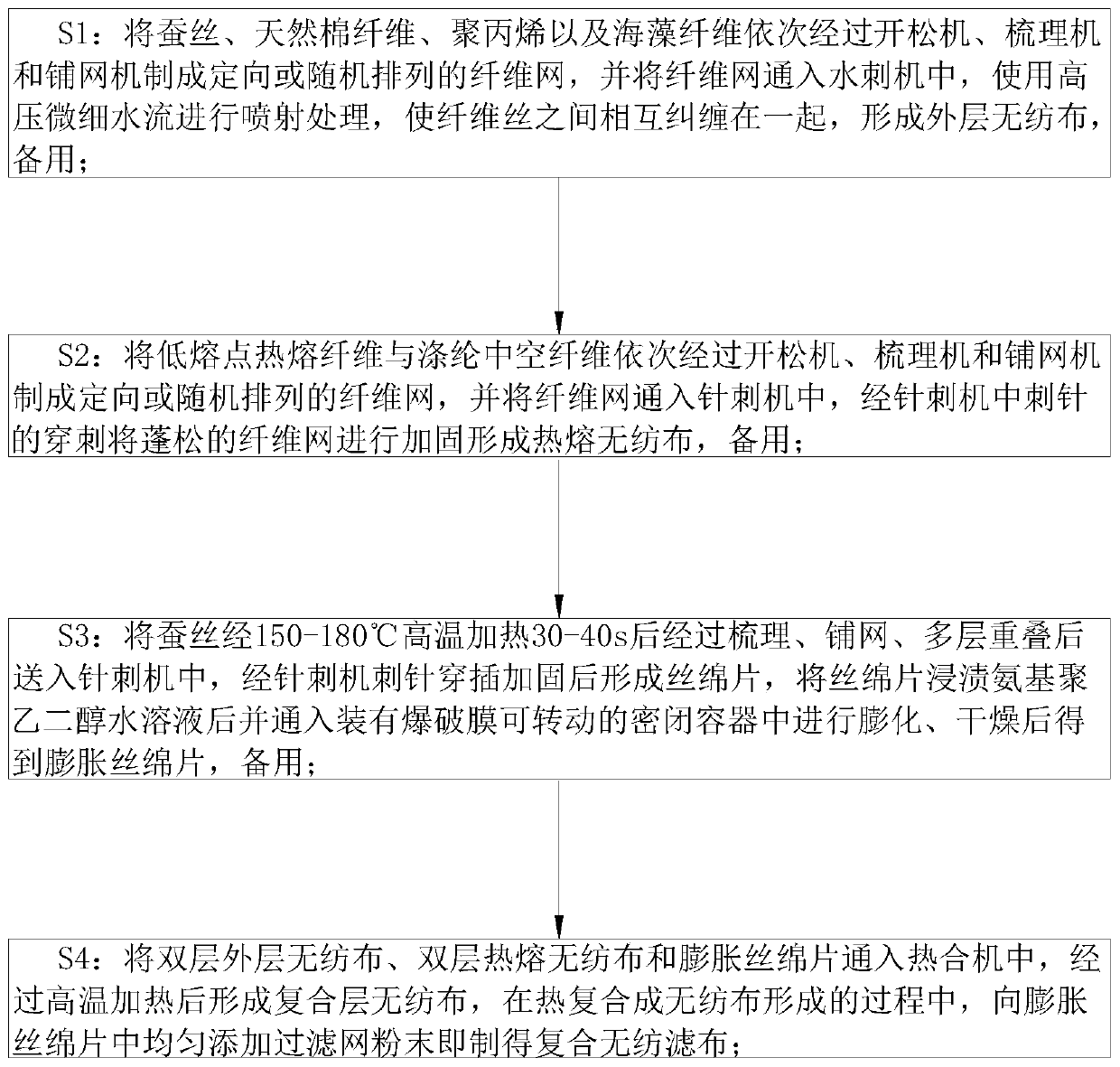

[0027] Such as Figure 1 to Figure 4 Shown, the preparation method of a kind of composite layer nonwoven fabric of the present invention, the preparation method of this composite layer nonwoven fabric comprises the following steps:

[0028] S1: Make silk, natural cotton fiber, polypropylene and seaweed fiber sequentially through the opening machine, carding machine and web laying machine to form oriented or randomly arranged fiber webs, and pass the fiber webs into the hydroentanglement machine, and spray them with high-pressure fine water flow processing, so that the fibers are entangled with each other to form an outer layer of non-woven fabric for use; polypropylene is blended with cotton fibers, silk and seaweed fibers, and the outer layer of non-woven fabric formed by spunlace itself has Strong air permeability and hygroscopicity, using it as the outer non-woven fabric can not only play a covering role, but also make the prepared composite non-woven fabric have better air...

Embodiment approach

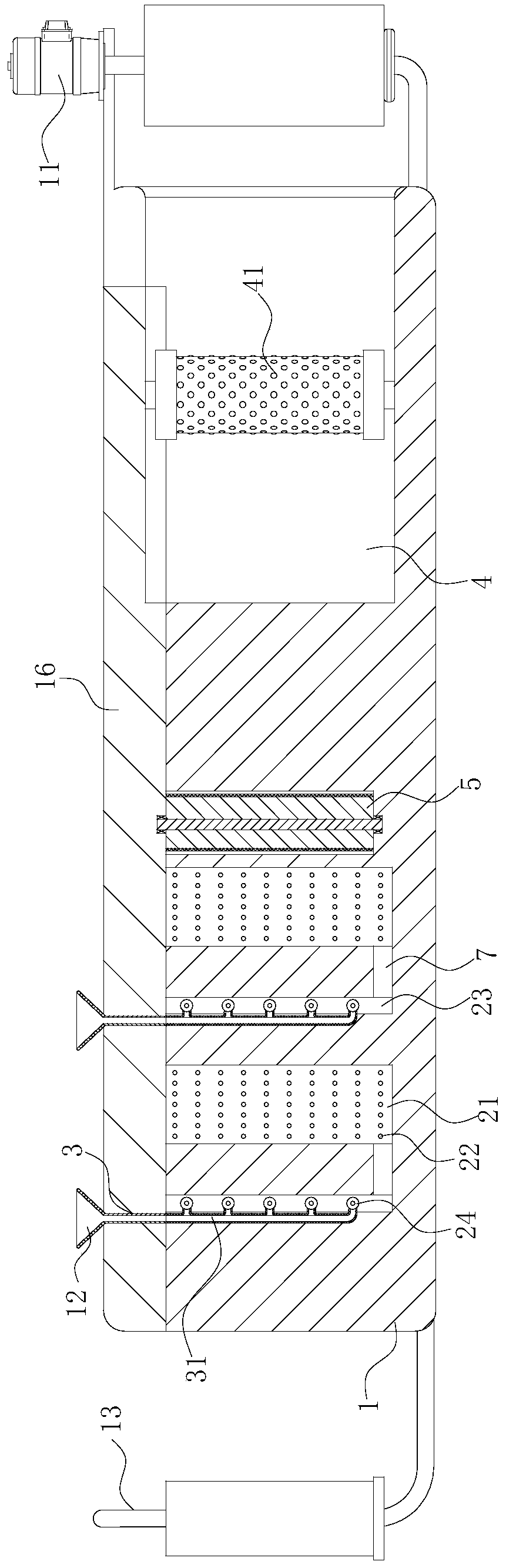

[0035] As an embodiment of the present invention, the modified tank 15 is located between the first cavity 2 and the second cavity 4, and a rotating groove is provided; the rolling groove is connected with a rolling roller 5 in rotation; the rolling groove The surface of the pressure roller 5 is covered with a rubber layer; when working, when the expanded silk floss sheet passes through multiple first cavities 2 airflow impacts, it continues to move forward, and contacts with the rolling rollers 5 in the rotating groove, so that the expansion The surface of the silk floss sheet is uniformly squeezed, thereby making the internal structure of the expanded silk floss sheet denser, making the fiber filaments have a stronger interception effect on the adsorptive particles, and effectively avoiding the thermal compounding of the adsorbent particles inside the expanded silk sheet after shaking. Dropping occurs before, thereby reducing the performance of the filter cloth produced, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com