Grabbing mechanism of manipulator

A technology of grasping mechanism and manipulator, which is applied in the field of manipulators, can solve the problems that parts of the manipulator cannot be rotated in a separate direction, cannot be used for product clamping, and reduce the usability of manipulators, etc., and achieve stable adjustment, improved usability, and easy adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

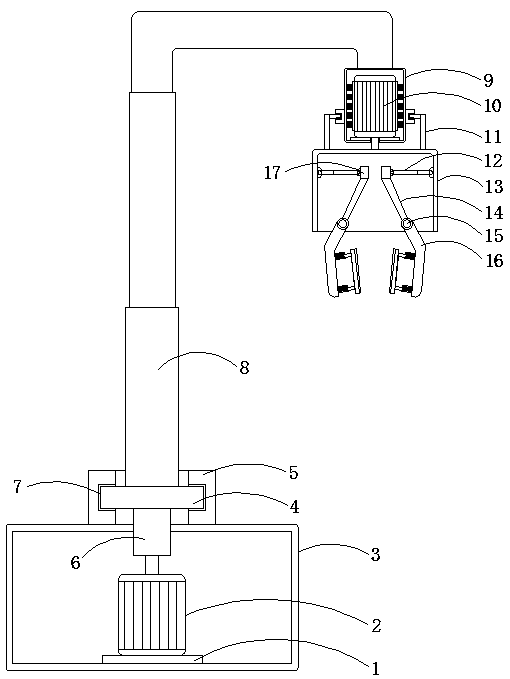

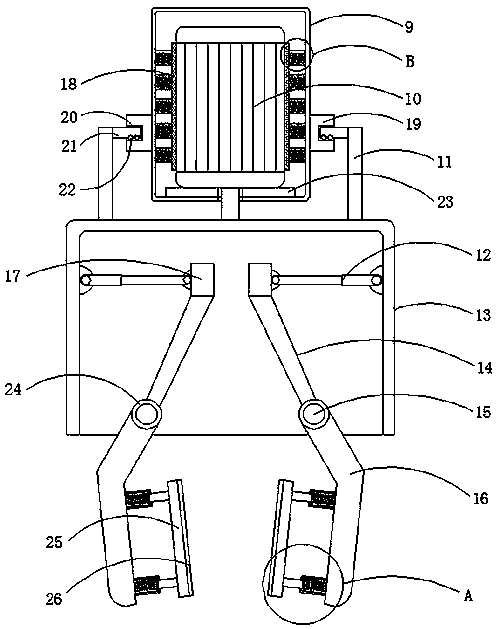

Embodiment 1

[0024] Embodiment one, with reference to figure 2 , image 3 and Figure 5 : a manipulator grabbing mechanism, including a hollow seat 3, a protective shell 9 and a connecting seat 13, the inside of the connecting seat 13 is a hollow structure, and the bottom of the connecting seat 13 is an open structure, which can be grasped inside the connecting seat 13 The position of plate 16 is installed and fixed, and round bar 15 is all welded near the bottom both sides edges between the front and rear sides inner surface walls of connecting seat 13, and connecting seat 13 can weld and fix to the position of round bar 15, and the outer of round bar 15 The surface sliding sleeve is provided with a roller 24. Since the roller 24 is slidably sleeved on the round rod 15, the roller 24 can rotate stably. There are two rollers 24, and the tops of the two rollers 24 are welded with linkage plates. 14. The top of the linkage plate 14 is welded with a mounting plate 17. The position of the m...

Embodiment 2

[0025] Embodiment two, refer to figure 1 , figure 2 and Figure 4: the inner bottom surface of the protective shell 9 is equipped with a first buffer plate 23, the vibration generated when the first motor 10 is started can be buffered by the first buffer plate 23, so that the first motor 10 is rotated stably, and the first buffer plate The top of 23 is equipped with the first motor 10, the bottom of the first motor 10 is provided with a rotating shaft, and the bottom end of the rotating shaft extends to the outside of the protective case 9, and the bottom end of the rotating shaft is welded with the top of the connecting seat 13, through the first motor 10 can drive the connecting seat 13 to rotate. In use, the direction of the connecting seat 13 can be adjusted independently, which is convenient to use. The first motor 10 adopts the model of BM71A6, and the inner surface walls on both sides of the protective shell 9 A plurality of shock-absorbing springs 32 are welded at e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com