Vibration forming platform for casting mold

A vibration forming and platform technology, applied in casting forming equipment, casting molds, casting mold components, etc., can solve problems such as incomplete vibration, achieve smooth casting surface, improve casting quality, and prevent excessive cooling effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

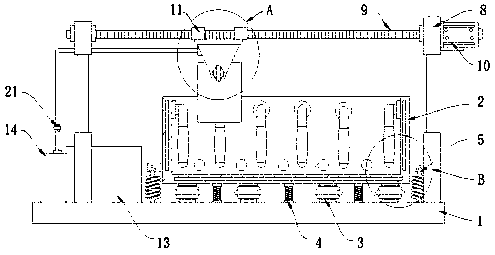

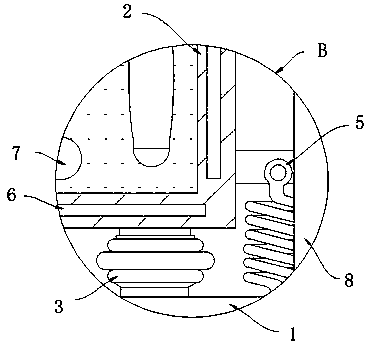

[0024] refer to Figure 1-2 , a casting mold vibration molding platform, including a platform base 1, the upper surface of the platform base 1 is provided with a vibration box 2, the inside of the vibration box 2 is filled with a sand-water mixture, and the sand-water ratio of the sand-water mixture is 6:4 , The specifications of the sand in the sand-water mixture are all fine sand passing through a 50-mesh sieve.

[0025] A plurality of air springs 3 and support springs 4 are fixedly connected between the vibration box 2 and the platform base 1, and a tension spring 5 is fixedly connected to the bottom end of the outer surface of the vibration box 2, and the bottom end of the tension spring 5 is fixedly connected to the platform base 1, A heating plate 6 is arranged inside the box body of the vibration box 2 , and a plurality of vibrators 7 are arranged on the inner side wall and the inner bottom wall of the vibration box 2 .

[0026] In this embodiment, by arranging a plura...

Embodiment 2

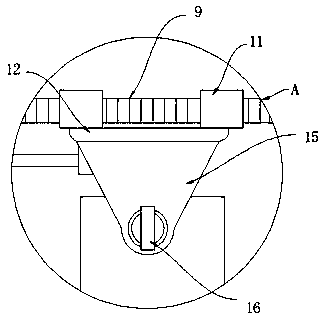

[0028] refer to Figure 3-5 , different from Embodiment 1, the surface of the platform base 1 is provided with a lifting frame 8, the cross bar of the lifting frame 8 is made of a screw rod 9, and the lifting frame 8 is a rectangular frame composed of an electric telescopic rod, a longitudinal rod and a screw rod 9 Structure, the four electric telescopic rods use the PLC controller to control the lifting synchronously.

[0029] The screw mandrel 9 extends to the right side of the lifting frame 8 and is fixedly connected with a servo motor 10. The surface of the screw mandrel 9 is threadedly connected with a screw nut block 11, and the lower surface of the screw mandrel nut block 11 is connected with the same horizontal block 12. The lower surface of the block 12 is fixedly connected with a mold clamping assembly, and the clamping assembly for clamping the mold includes a clamping lower opening concave block 15 fixedly connected to the lower surface of the cross block 12, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com