An instrument processing device and processing method for food safety detection and analysis

A processing device and food safety technology, applied in the field of instrument processing devices for food safety detection and analysis, can solve the problems of time-consuming, labor-intensive, unfavorable cleaning, and difficulty in cleaning, and achieve the effect of expanding the scope of use and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

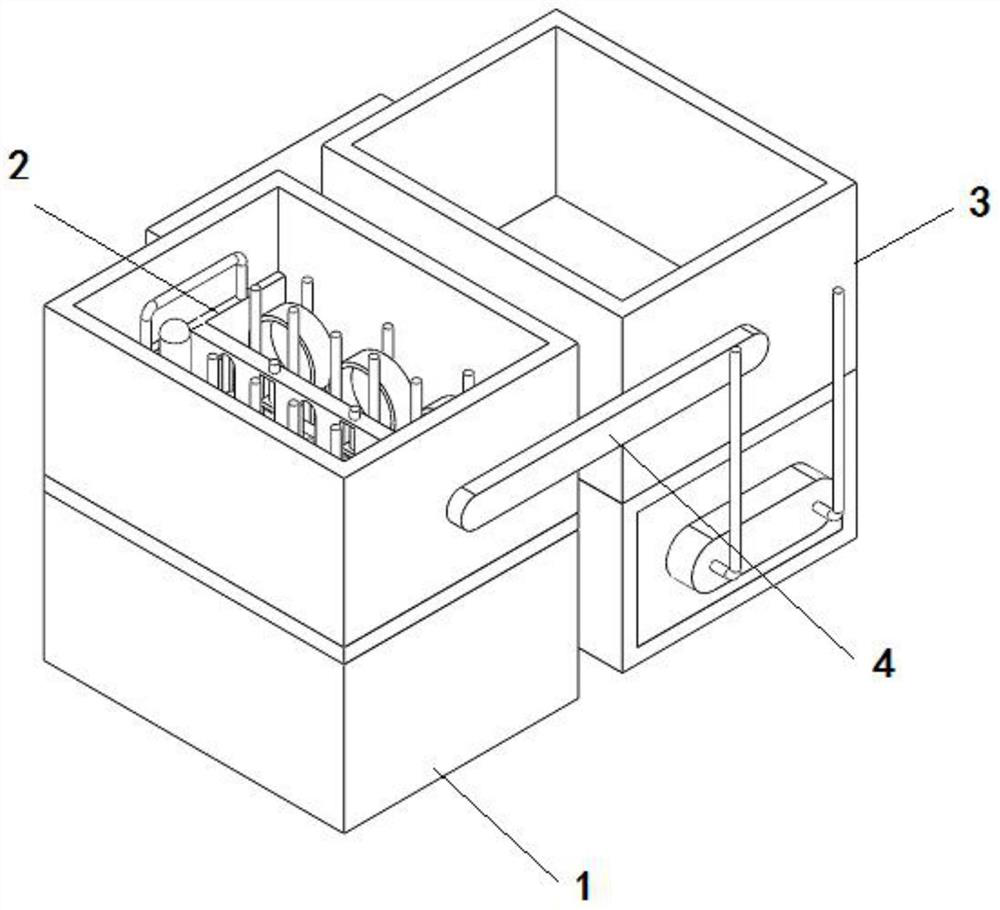

[0041] Such as figure 1 The shown instrument processing device for food safety testing and analysis includes an instrument ultrasonic cleaning instrument 1 and an instrument placement rack 2 movable inside the instrument ultrasonic cleaning instrument 1 . Cleaning instrument 3;

[0042] The left and right sides of the ultrasonic cleaner 1 are rotatably equipped with a connecting plate 4 , and the end of the connecting plate 4 away from the ultrasonic cleaner 1 is rotatably connected with the instrument cleaner 3 .

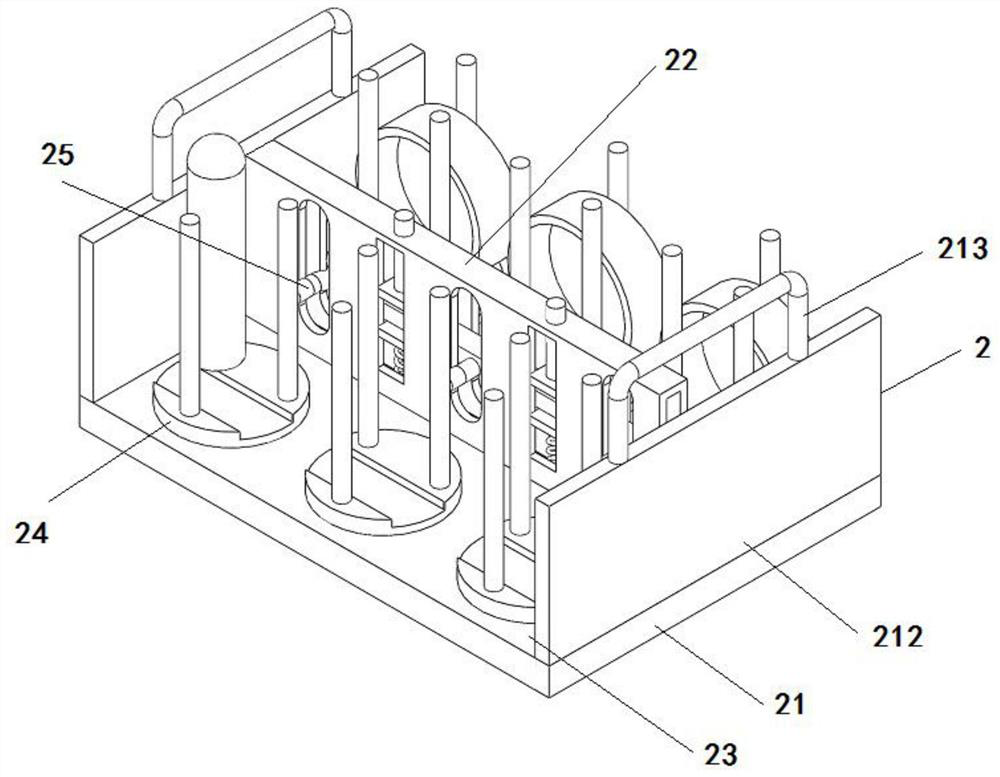

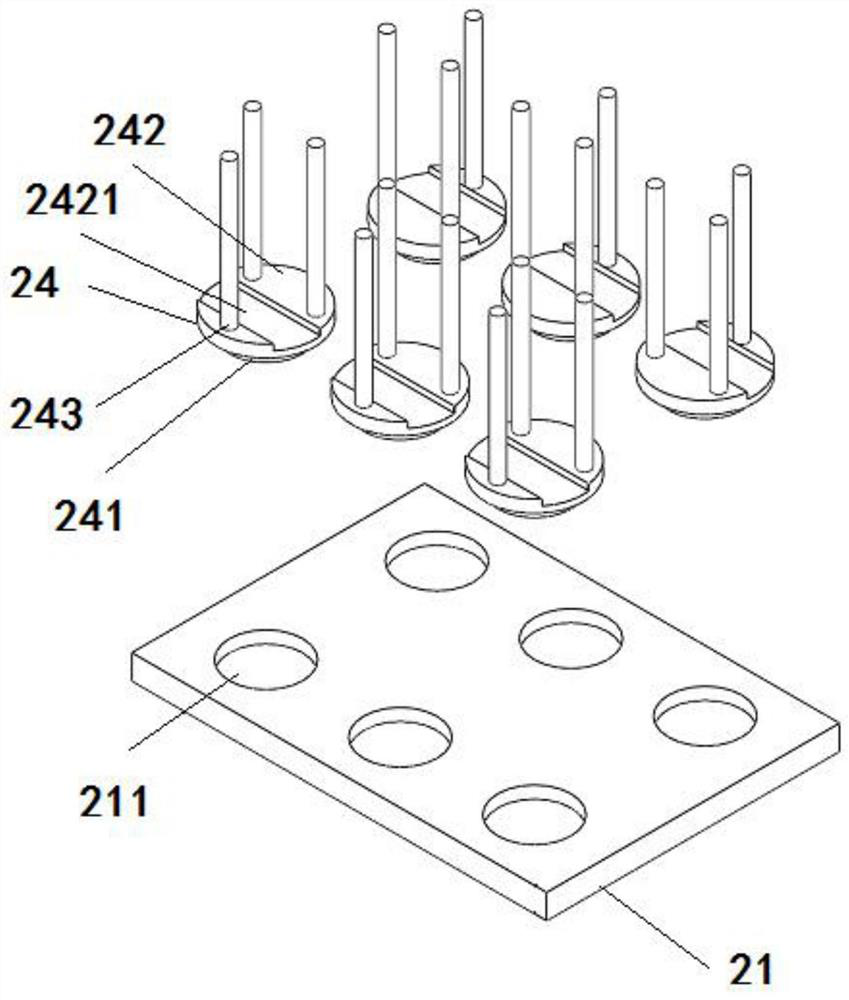

[0043] Such as figure 2 As shown, the instrument placement rack 2 includes a bottom plate 21 and a partition plate 22 fixedly installed in the center of the top surface of the bottom plate 21. The partition plate 22 divides the top surface of the bottom plate 21 into two relatively symmetrical placement areas 23. There are rotating placement devices 24 evenly distributed in the area 23, and a spray cleaning device 25 matched with the rotating placement device 24...

Embodiment 2

[0065] A method for processing an instrument processing device for food safety detection and analysis, the method includes the following steps:

[0066] Step a: Put the petri dish and test tube to be cleaned into the rotating placement device 24 respectively, start the instrument ultrasonic cleaner 1, and perform ultrasonic cleaning on the petri dish and test tube to be cleaned;

[0067] Step b: After the ultrasonic cleaning is completed, hold the inverted U-shaped handle 213 in hand, move the instrument placement rack 2 into the instrument cleaning instrument 3, connect the outlet pipe 34 to the pipe connector 256, start the water pump 33, and clean the water in the rotating placement device 24. Rinse the petri dishes and test tubes to be cleaned;

[0068] Step c: After flushing, move the rotating device 24 out of the instrument cleaning device 3, open the connecting valve 323, and put the water in the device cleaning device 3 into the recovery box 322 for recovery.

[0069]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com