Engine rapid combustion device suitable for low-evaporation characteristic fuel

A combustion device and engine technology, which is applied in the direction of combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problem of insignificant improvement in the combustion speed of large-bore engines, increased weight and volume costs of ignition coils, and aggravated spark plug electrode wear, etc. problems, to achieve the effect of improving ignition stability and reliability, speeding up flame propagation, and speeding up combustion flame propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

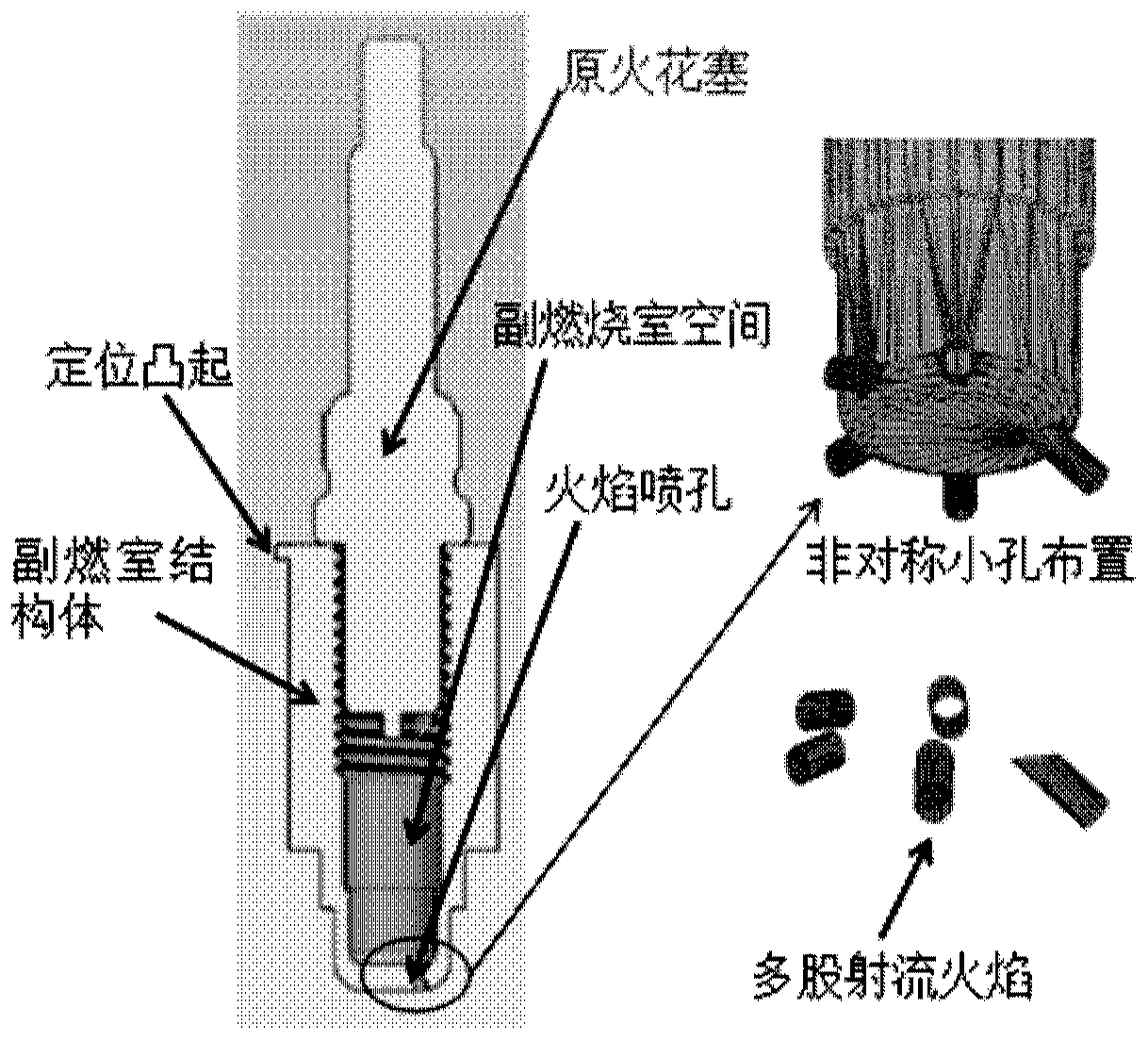

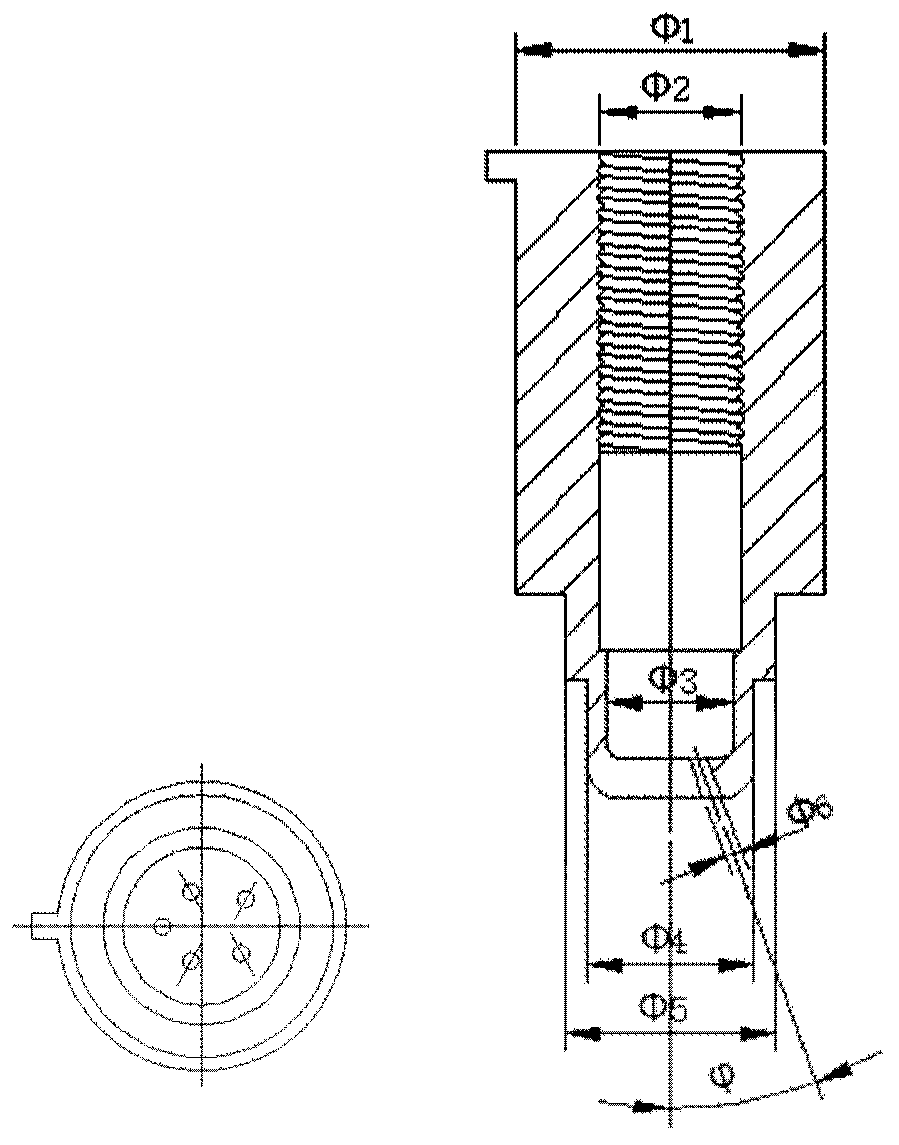

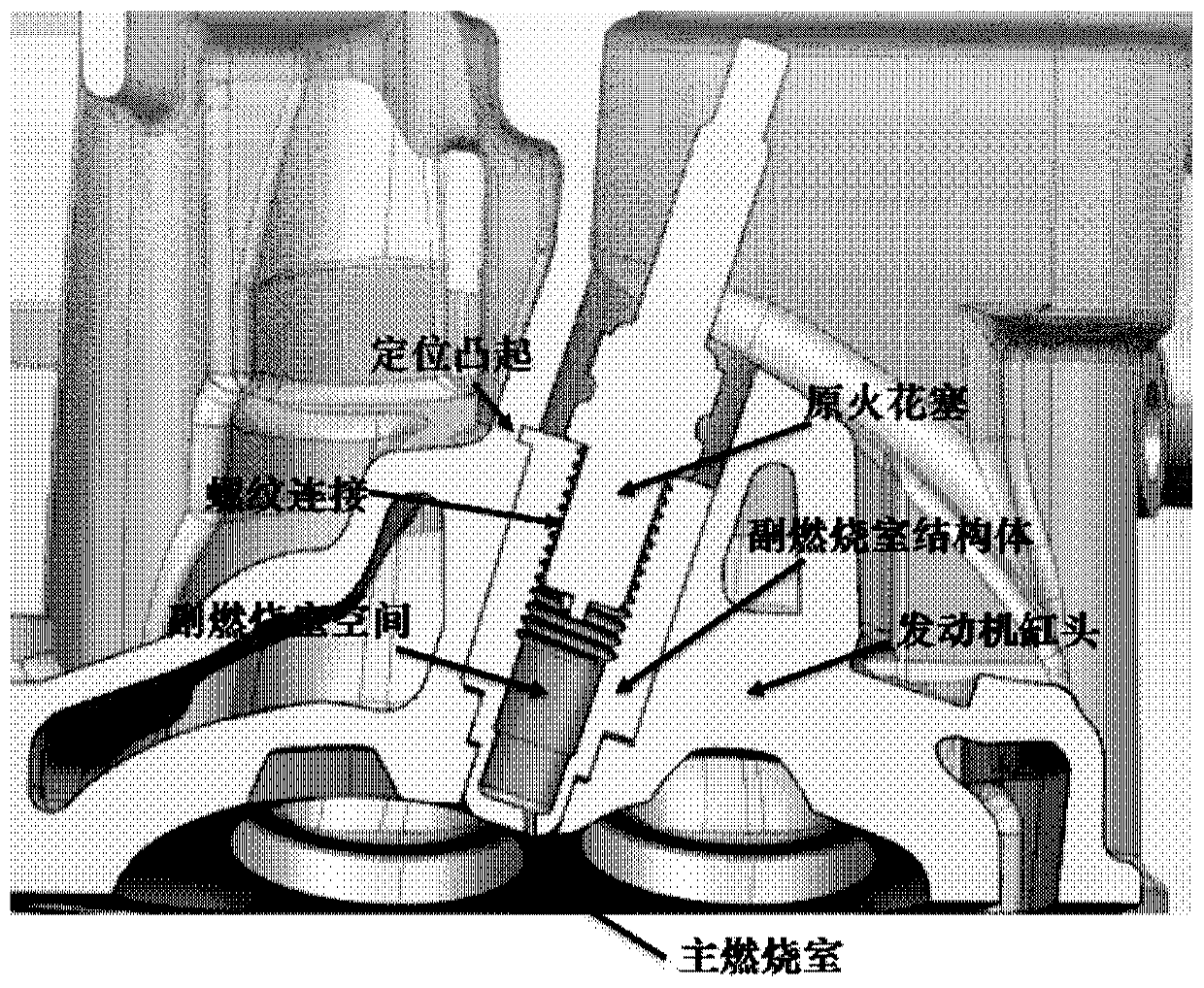

[0026] In order to improve the combustion speed and combustion stability of engines with low-evaporation-characteristic fuels, promote the rapid combustion of large-bore engines, and then improve their workability, a scheme for rapid combustion devices for engines with low-evaporation-characteristic fuels is proposed. The basic principle is: an auxiliary combustion chamber is formed at the original spark plug, and the auxiliary combustion chamber is positioned and connected with the engine through the positioning protrusion and the tablet pressing device. The initial flame is generated by the discharge of the original spark plug in the auxiliary combustion chamber, and then the flame is generated in the auxiliary combustion chamber. And develop rapidly, and then generate multiple jet flames through multiple flame nozzles connecting the auxiliary combustion chamber and the main combustion chamber, and the multiple jet flames are injected into the main combustion chamber at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com