Blade tip coating of a blade of a gas turbine engine

A gas turbine and engine technology, applied in the direction of engine components, machines/engines, blade support components, etc., can solve problems such as damage and instability of other parts, and achieve the effects of improving functionality, improving reliability, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

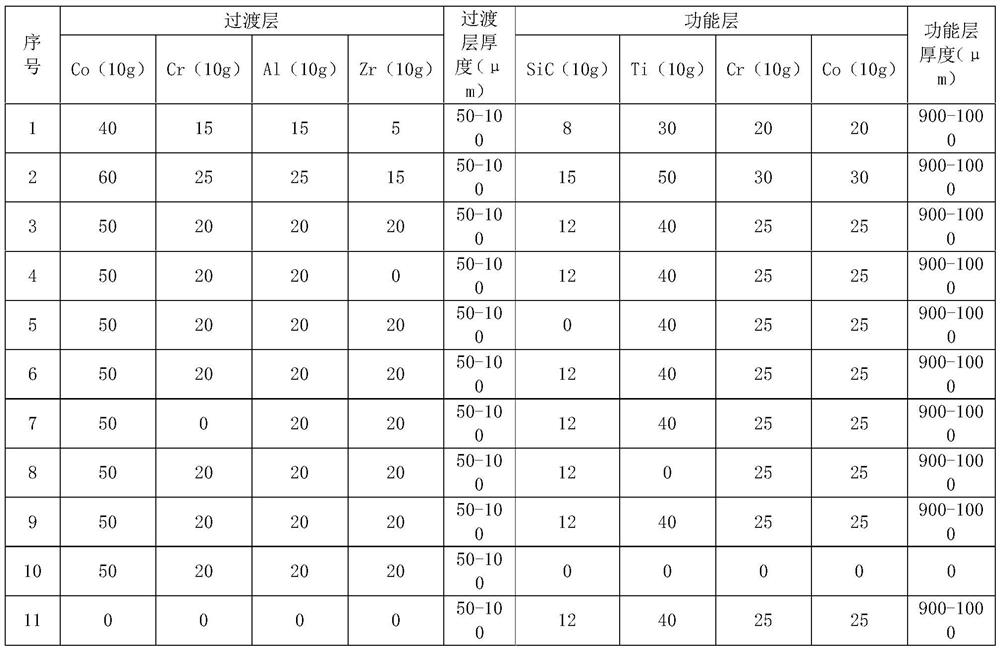

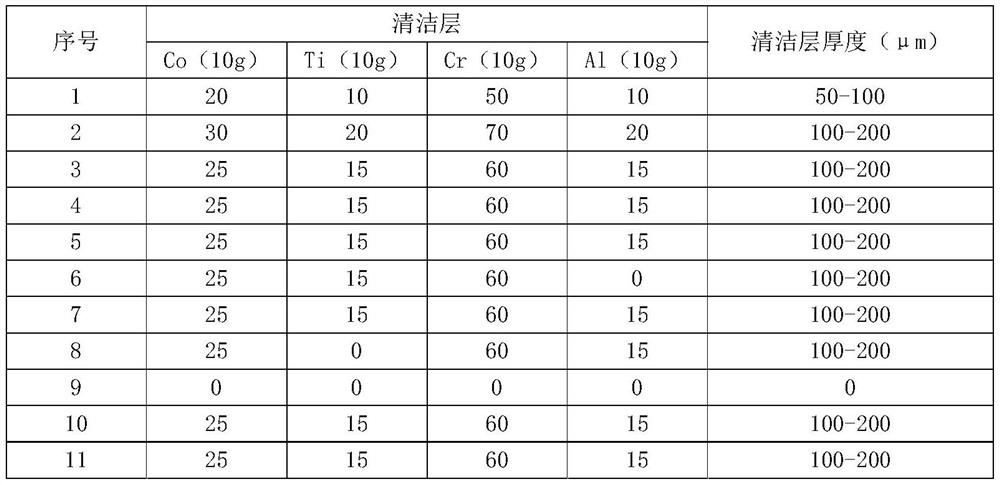

[0019] In the embodiment, prepare the same board as the blade tip, and then configure the raw materials of the transition layer, functional layer and cleaning layer:

[0020] S1. First, carry out surface friction treatment on the plate;

[0021] S2. Ball mill 200-500 meshes of Co, Cr, Al, Zr under the protection of an inert gas for no less than 3 hours, and then put it into a plasma spraying device to spray the tip of the blade under the protection of an inert gas, and the ionized gas is hydrogen;

[0022] S3. Ball mill 200-500 meshes of Co, Cr, and Ti under the protection of an inert gas for no less than 3 hours, then put 200-500 meshes of SiC, and then put it into a plasma spraying device to protect the tip of the blade under the protection of an inert gas. Spraying is carried out on the tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com