Pre-grouting reinforcement method for working face crossing through faults, and grouting device

A technology of grouting device and working face, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve problems such as roof slabs and leaky roofs, improve the gas drainage effect, reduce the weakening of rock formations, The effect of reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a pre-grouting reinforcement method for crossing a fault in a working face, which includes the following steps:

[0038] Step 1: According to the specific geological conditions of the coal mining face, adopt the The drill bit is used to pre-drill to form a pre-drilled hole, the elevation angle of the pre-drilled hole is 8°-14°, and the hole depth is 4-8m.

[0039] Step 2: Grouting the pre-drilled holes in step 1, injecting reinforcement materials to block the fissures in the surrounding rock, and stopping the grouting until the fissures in the surrounding rock return to the grout.

[0040] Specifically, due to the fracture of the shallow surrounding rock, after the reinforcement material is injected into the pre-drilled hole, under the joint action of the grouting pressure and the coal seam gas pressure, the grouting will return along the surrounding rock cracks around the pre-drilled hole, which means that the grouting reinforcement is comple...

Embodiment 2

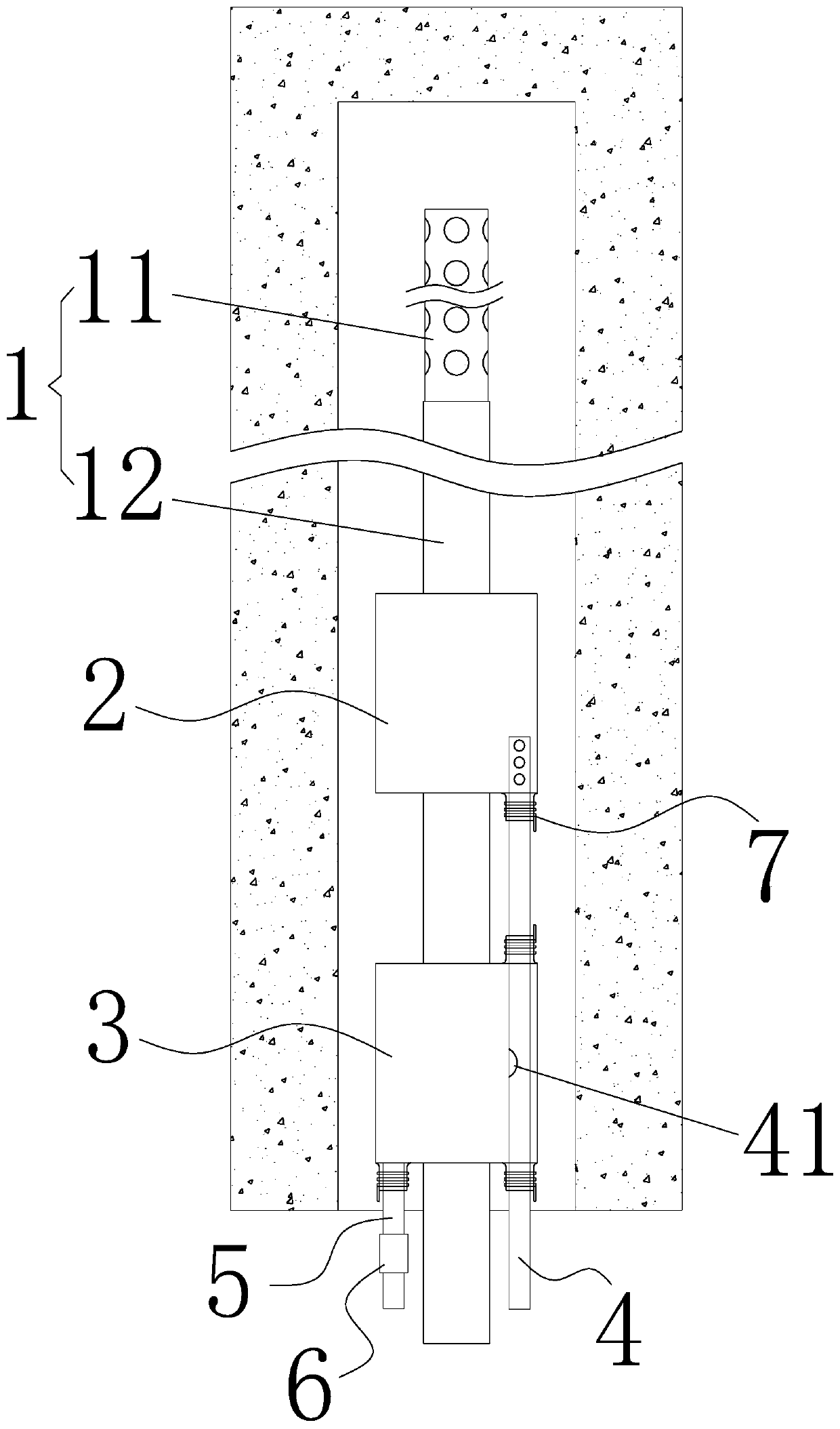

[0050] refer to figure 1 , this embodiment also discloses a grouting device used in the pre-grouting reinforcement method for crossing faults in the working face. The grouting device includes a first grouting pipe 1, a first elastic bladder 2, a second elastic bladder 3. The second grouting pipe 4, the grouting pipe 5 and the grouting blasting valve 6. In this embodiment, the first grouting pipe 1 is an iron pipe, and the first grouting pipe 1 includes a grouting flower The pipe 11 and the grouting flowerless pipe 12, the grouting flowery pipe 11 and the grouting flowerless pipe 12 communicate to form the first grouting pipe 1, and the grouting flowery pipe 11 is far away from the end of the grouting flowerless pipe 12 The head is the grouting head of the first grouting pipe 1 , and the first elastic bag 2 and the second elastic bag 3 are sleeved on the grouting seamless pipe 12 along the axial direction of the first grouting pipe 1 .

[0051] Further, the end of the grouting...

Embodiment 3

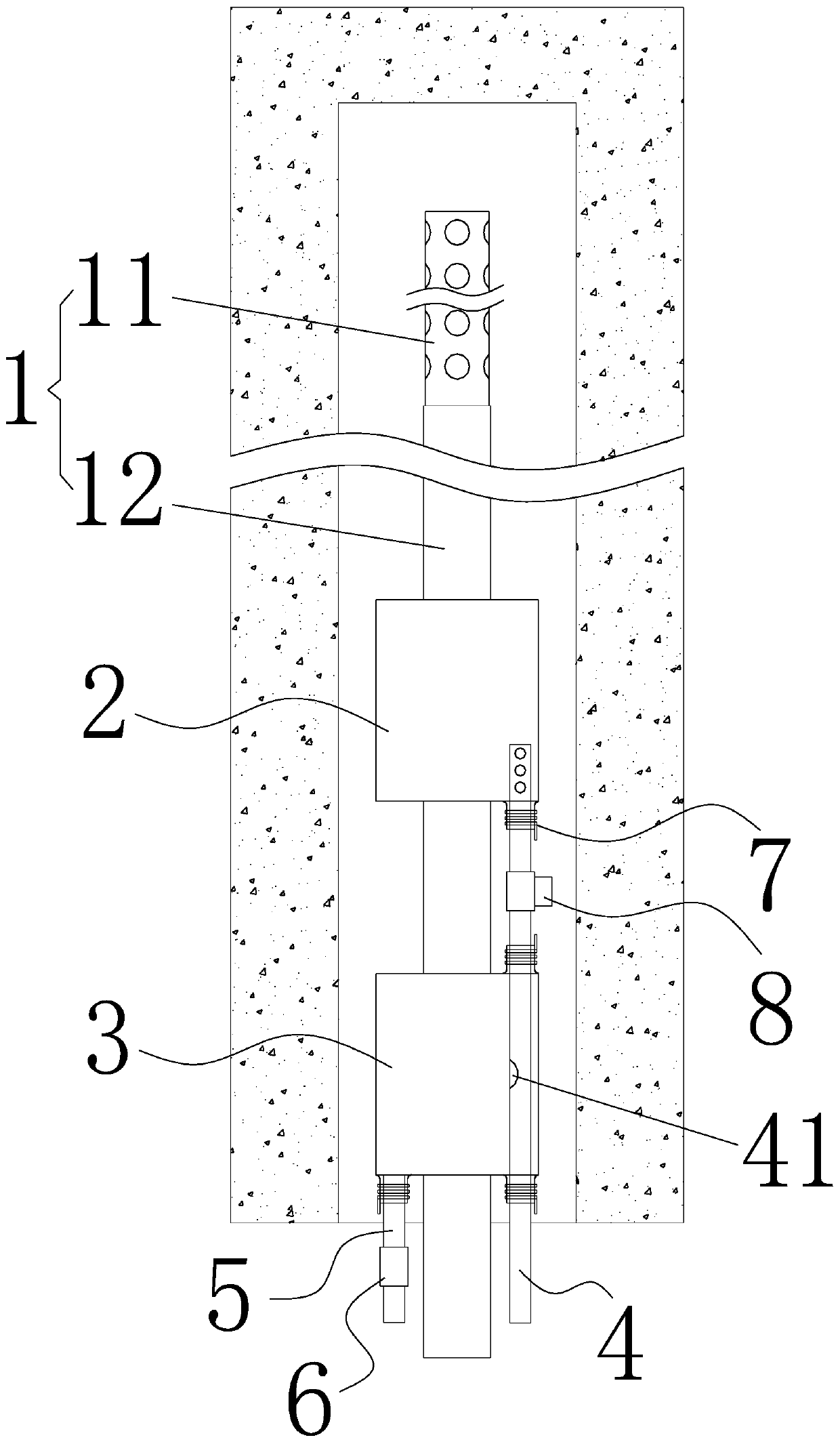

[0058] refer to image 3 In this embodiment, on the basis of the second embodiment, a three-way air pressure burst valve 8 is also provided on the second grouting pipe 4 between the first elastic bladder 2 and the second elastic bladder 3, and the three The blasting pressure of the air pressure blasting valve 8 is lower than the blasting pressure of the pulp return blasting valve 6, ensuring that the three-way air pressure blasting valve 8 bursts first after being pressurized, so as to realize the medium-depth gap between the first elastic bladder 2 and the second elastic bladder 3. Hole or deep hole grouting, to further ensure the sealing effect, but also improve the fixation of the first grouting pipe 1, to prevent the first grouting pipe 1 received reaction force during high-pressure grouting and pop out of the deep hole or deep hole Holes, unable to achieve grouting in deep or deep holes.

[0059] Specifically, the second grouting pipe 4 is grouted externally, and the rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com