A kind of fully bio-based unsaturated polyester prepolymer for dynamic vulcanization with polylactic acid and preparation method thereof

A dynamic vulcanization and prepolymer technology, applied in the field of polymer materials, can solve the problems affecting the biodegradability of polylactic acid, the loss of blend strength and modulus, etc., to ensure full bio-based characteristics, low price, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of the all bio-based unsaturated polyester prepolymer that is used for dynamic vulcanization with polylactic acid, comprises the following steps:

[0042] Step 1. Weigh the polybasic acid and diol in the container according to the proportion, add a certain amount of polymerization inhibitor, pass through the protective gas, heat and stir for a period of time to undergo preliminary esterification, and obtain a preliminary esterification product.

[0043] In a specific embodiment of the present invention, the polybasic acid in step 1 is formed by mixing citric acid and itaconic acid;

[0044] Preferably, citric acid accounts for 60-90% (such as 60%, 65%, 70%, 75%, 80%, 85%, 90%) of the molar weight of polybasic acid; itaconic acid accounts for 10-90% of the molar weight of polybasic acid. 40% (such as 10%, 15%, 20%, 25%, 30%, 35%, 40%).

[0045] In a specific embodiment of the present invention, the dihydric alc...

Embodiment 1

[0063] In the embodiment of the present invention, a method for preparing a fully bio-based unsaturated polyester prepolymer for dynamic vulcanization with polylactic acid comprises the following steps:

[0064] Step 1. Weigh 17.9716g of polybasic acid and 8.6754g of 1,3-propanediol in a container, add 0.1332g of p-hydroxyanisole, pass nitrogen gas to fill the container, heat to 165°C and stir for 20min, then cool down To 145 ° C, stirring and melting for 20 minutes to undergo preliminary esterification, and obtain a preliminary esterification product; (wherein, the polybasic acid is a mixture of citric acid and itaconic acid, and the molar ratio of citric acid and itaconic acid is 0.08mol: 0.02mol; The molar ratio of carboxyl and hydroxyl groups in acid and 1,3-propanediol is 1:1.1; the amount of p-hydroxyanisole added is 0.5wt% of the total mass of polybasic acid and 1,3-propanediol);

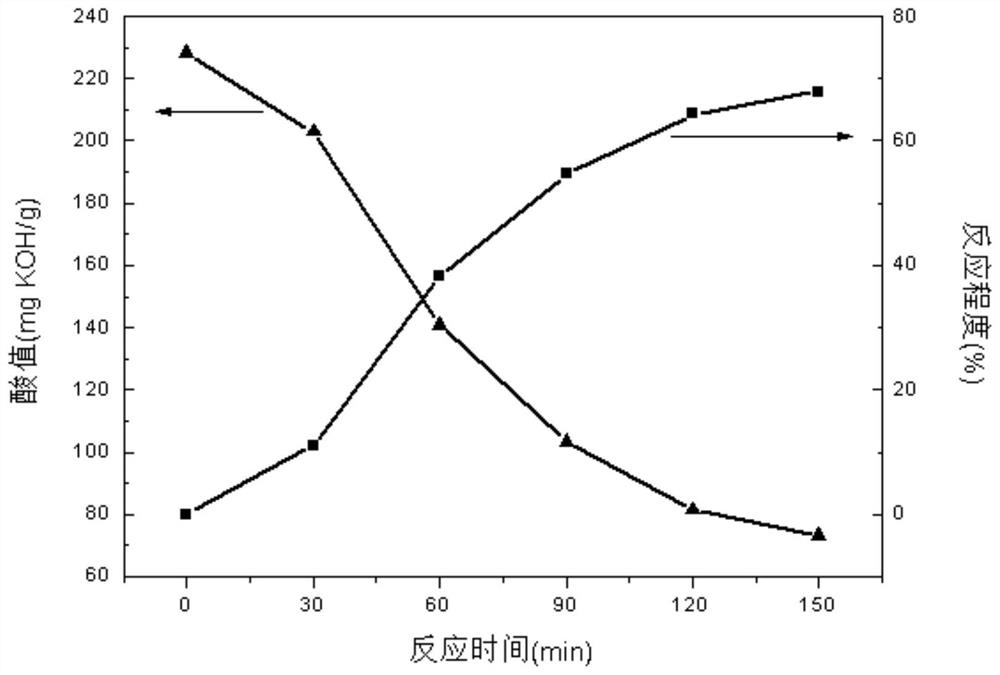

[0065] Step 2. The preliminary esterification product obtained in step 1 is maintained at...

Embodiment 2

[0080] The preparation method of the fully bio-based unsaturated polyester prepolymer used for dynamic vulcanization with polylactic acid in this example is different from the preparation method in Example 1 in that:

[0081] In step 1, take by weighing 22.3078g of 1,10-decanediol, and add 0.2014g of p-hydroxyanisole (wherein, the molar ratio of polyacid and 1,10-decanediol in carboxyl to hydroxyl is 1: 1.2); step 3, washing 7 times; other methods and steps are the same as those in Example 1, and will not be repeated here.

[0082] The fully bio-based unsaturated polyester prepolymer and polylactic acid prepared in this example were dynamically vulcanized, and the specific steps were the same as those in Example 1, which will not be repeated here.

[0083] The mechanical property test method of the polylactic acid / fully bio-based unsaturated polyester prepolymer blend prepared in this example is the same as that of Example 1, and will not be repeated here.

[0084] By testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com