A large slender ratio load system for underwater deployment and recovery of a manned submersible

A manned submersible technology with a large length and slenderness ratio, which is used in underwater ships, underwater operation equipment, special-purpose ships, etc. It can achieve the effect of safe and efficient deployment and recovery, avoiding sea surface wind, waves and gradient flow, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

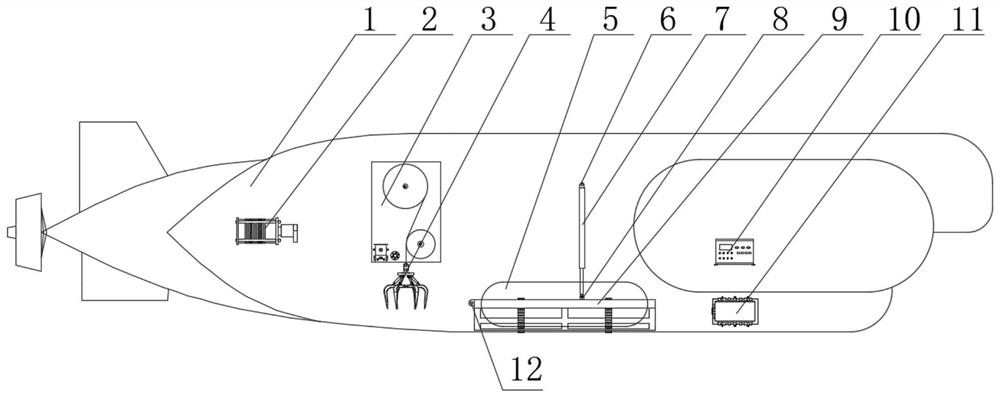

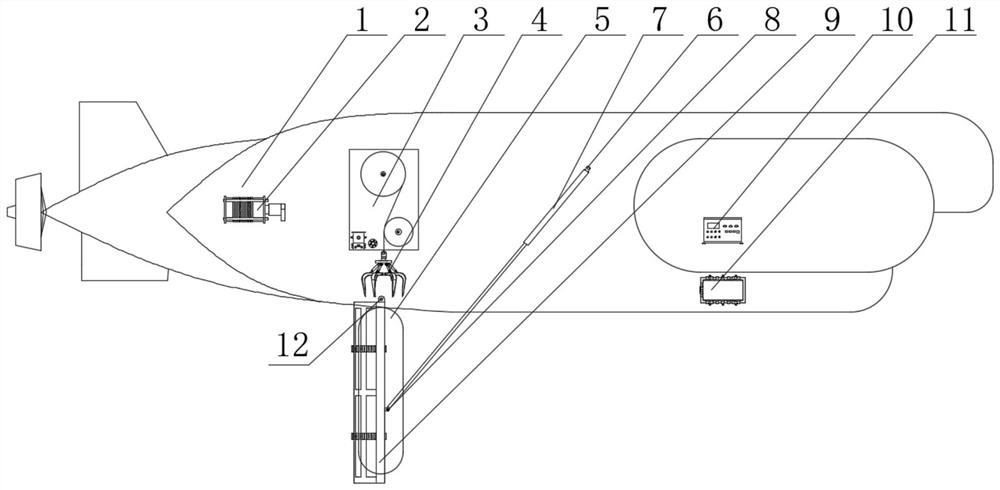

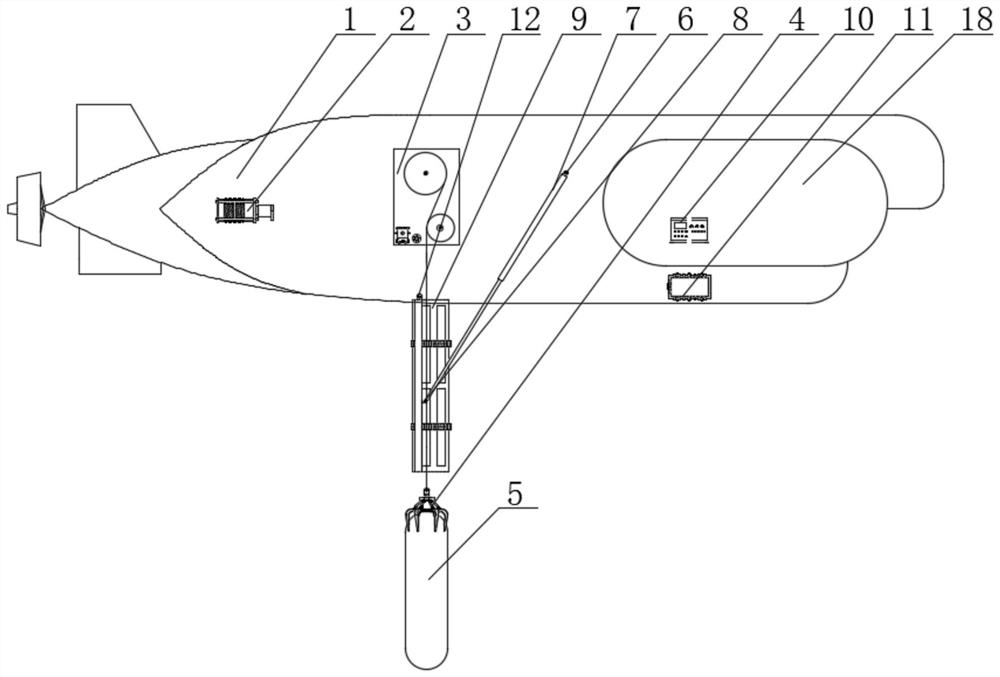

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the manned submersible of the present embodiment deploys and recovers the large slenderness ratio load system underwater, including the manned submersible 1, the manned submersible 1 is equipped with a manned cabin 18, and the manned cabin 18 is equipped with a manned cabin. A hydraulic source 2, a winch 3, an auxiliary mechanism 9 and an underwater power supply 11 are respectively installed on the manned submersible 1, and a control box 10 is installed inside the manned cabin 18;

[0024] The winch 3 is connected with a hook 4 through a load-bearing umbilical cable;

[0025] The installation structure of the auxiliary mechanism 9 is: comprising multi-stage hydraulic cylinders 7 arranged at intervals, the cylinder top of each multi-stage hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com