Towel cloth transverse cutting machine

A technology of terry cloth and cross-cutting machine, which is applied in the direction of textiles and papermaking, metal processing, and textile material cutting, etc. It can solve the problems of low degree of automation and terry cloth cannot be turned over automatically, so as to save production costs, orderly stack, The effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

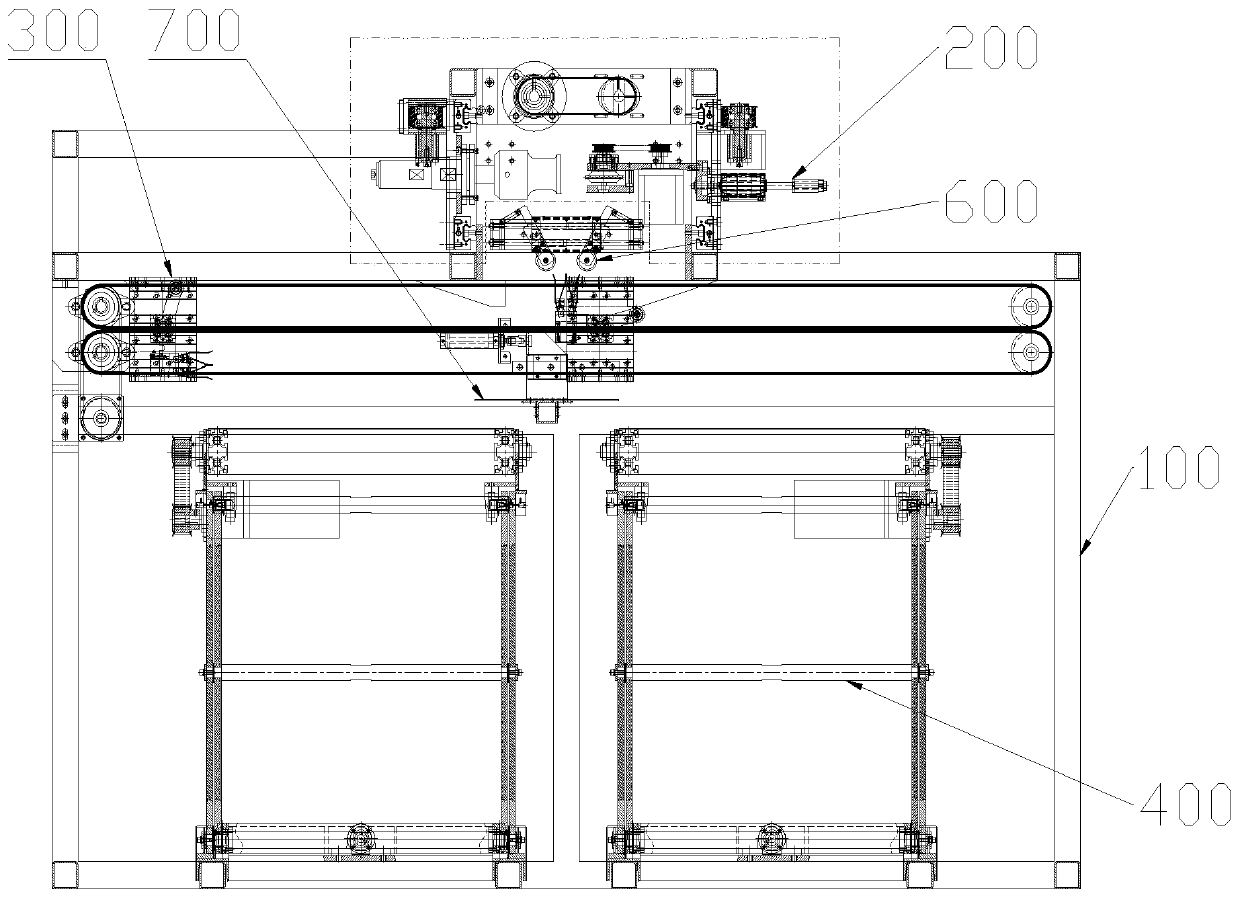

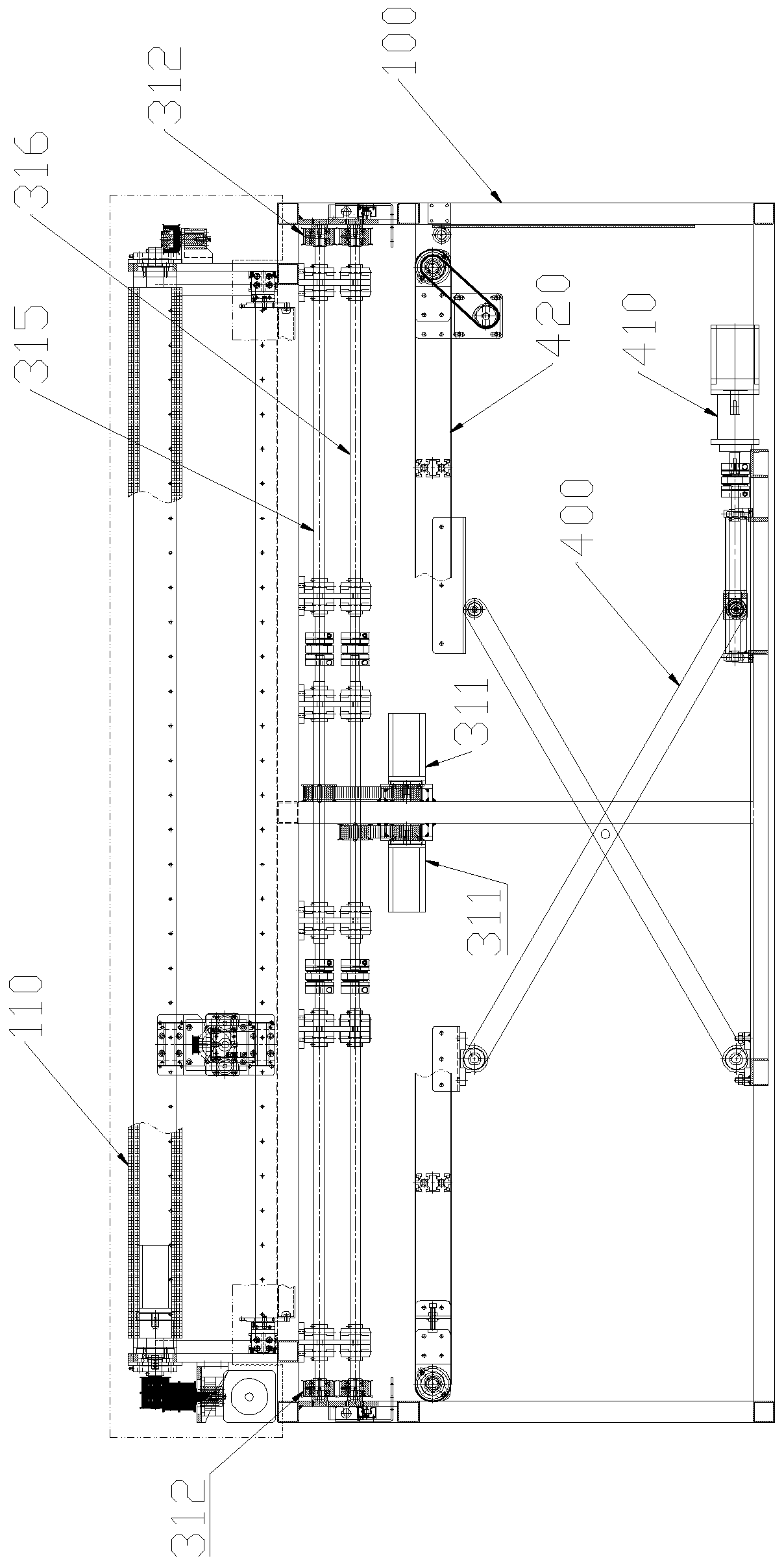

[0045] The present disclosure provides a terry cloth cross-cutting machine, such as figure 1 and figure 2 As shown, a frame 100 is included, and a cutting mechanism 200 , a grabbing mechanism 300 and a lifting mechanism 400 are installed on the frame 100 . A rubber roller 110 is installed on the top of the frame 100, and the terry cloth 500 is wound on the rubber roller 110 in rolls, and the end of the towel cloth 500 hangs vertically naturally. The rubber roller 110 is driven by the rubber roller stepping motor 111 to rotate intermittently, so as to coordinate with the action rhythm of the cutting mechanism 200 and the grabbing mechanism 300 to stably release the cloth.

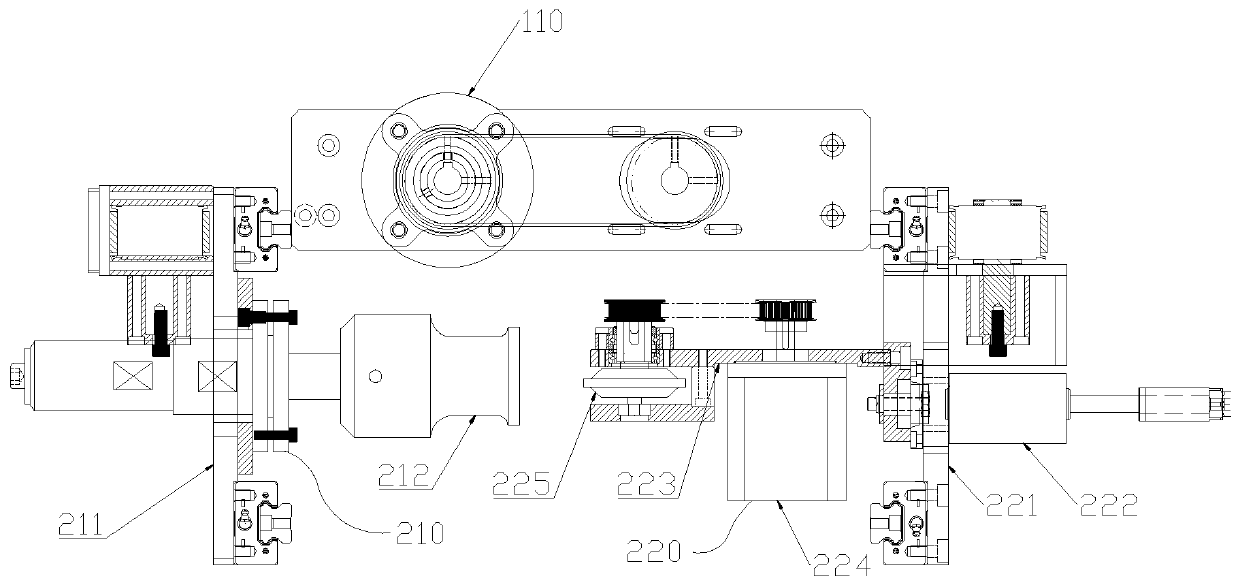

[0046] Such as Figure 3 to Figure 6 As shown, the cutting mechanism 200 is used for cross-cutting the terry cloth 500. The cutting mechanism 200 includes an ultrasonic vibrator assembly 210, a circular knife assembly 220 and a cross-cut synchronous drive mechanism 230. The ultrasonic vibrator assembly 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com