Grinding wheel for resin grinding

A grinding wheel and grinding technology, which is applied in the direction of bonded grinding wheels, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of increasing mechanical costs, increase the contact area, improve the pass rate, and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

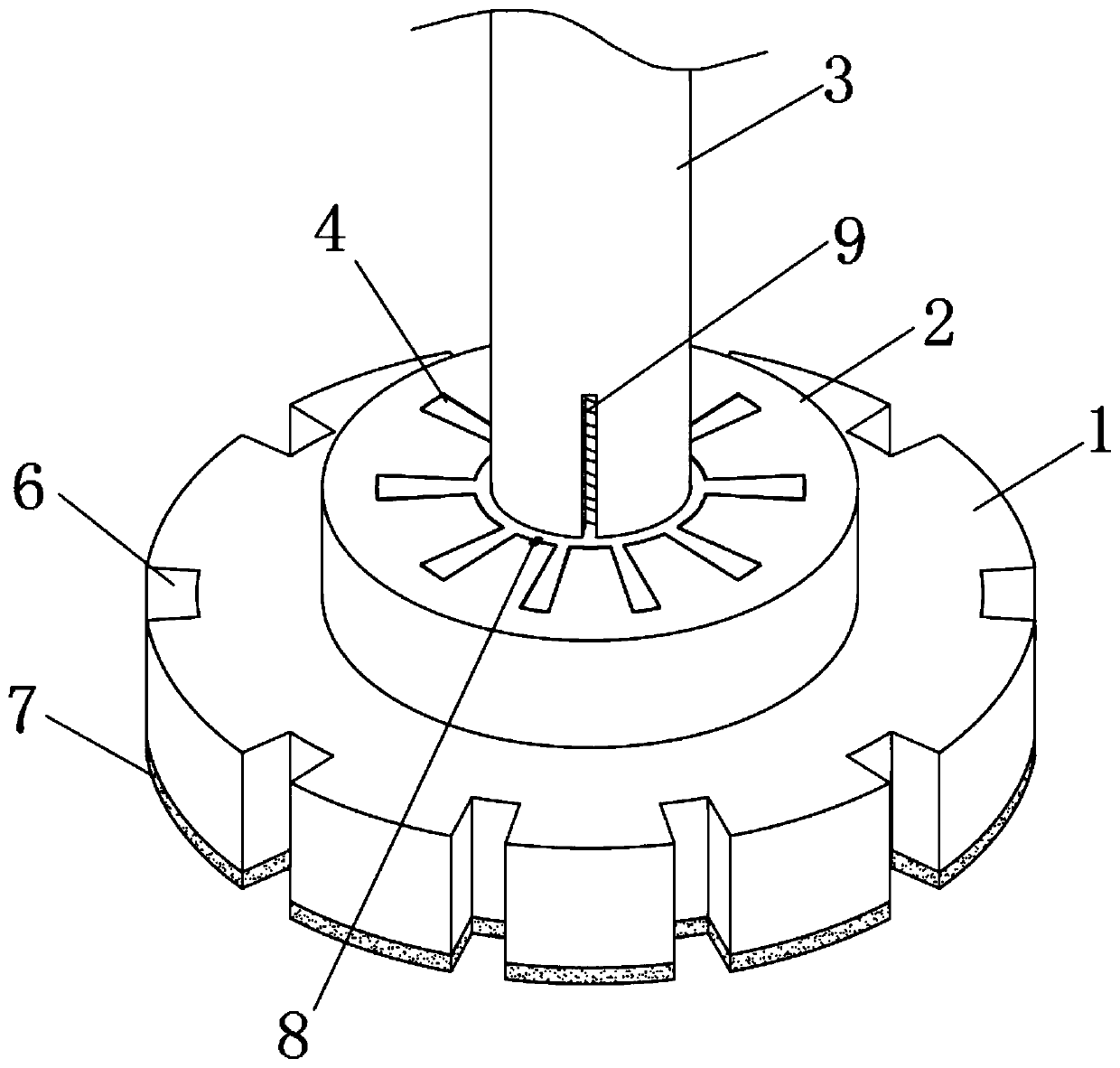

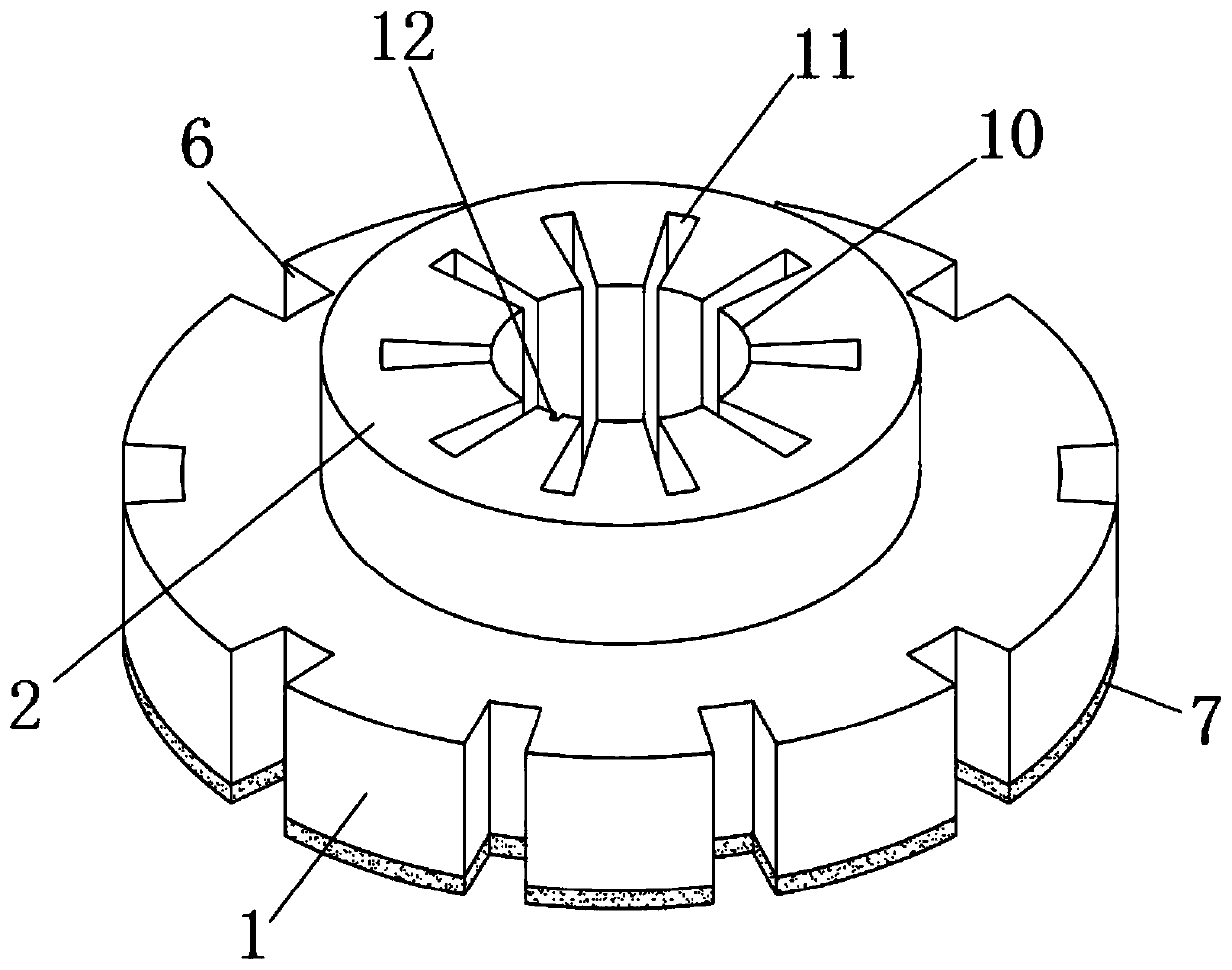

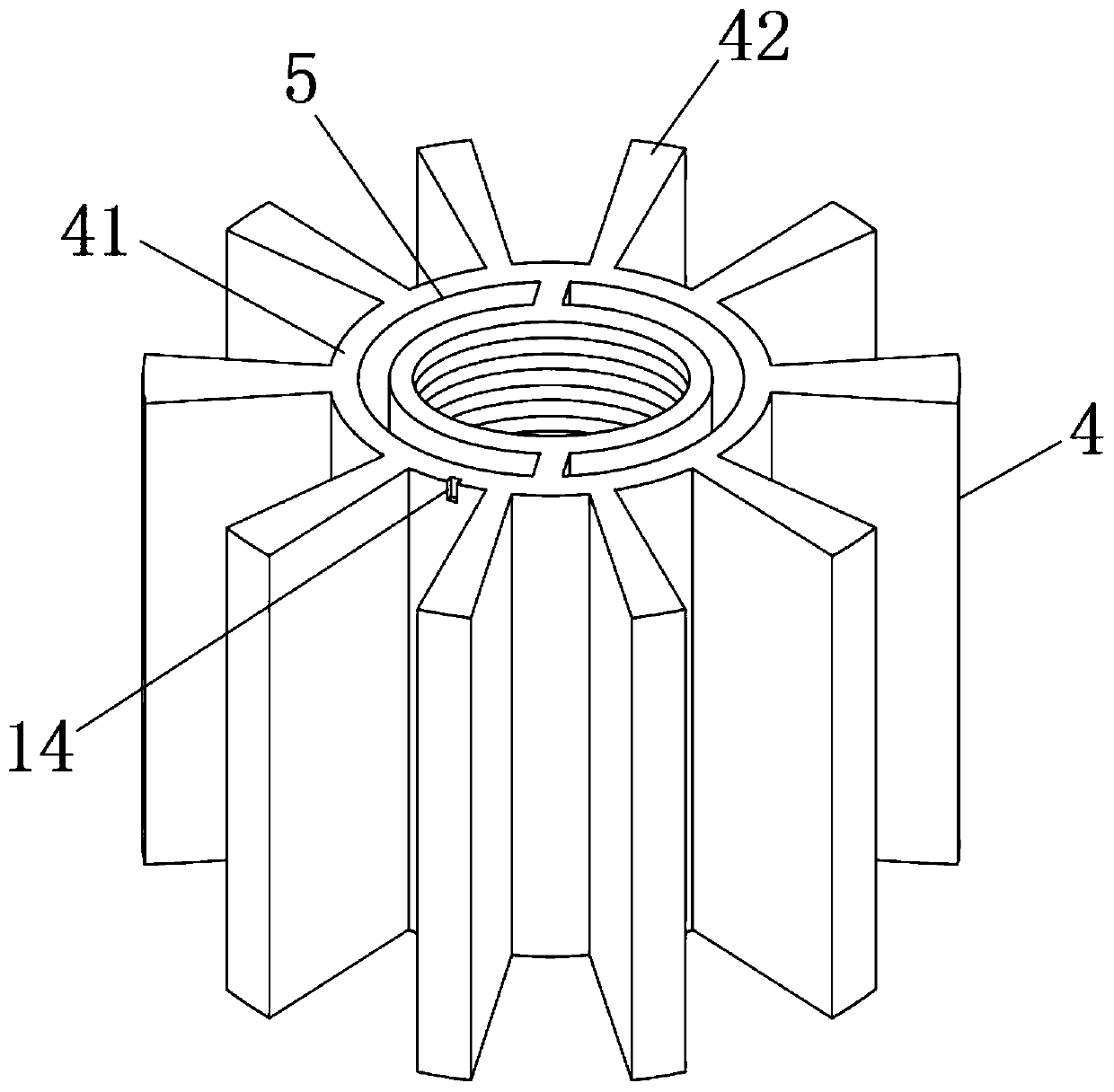

[0033] refer to Figure 1-6 , a resin grinding wheel, comprising a grinding wheel main body 1, a grinding sheet 7 is installed at the lower end of the grinding wheel main body 1, and a plurality of wedge-shaped grooves 6 are symmetrically opened on the side wall of the grinding wheel main body 1, which can realize the grinding wheel main body 1 pair of objects Intermittent grinding, to avoid continuous friction between the grinding wheel body 1 and the object. When the grinding point of the object and the grinding wheel body 1 is located in the wedge-shaped groove 6, the grinding point can be in contact with the air, which reduces the temperature of the grinding point to a certain extent and avoids the temperature of the object. If the rise is too fast, the main body of the grinding wheel 1 is provided with an annular cooling chamber 13, and the annular cooling chamber 13 is surrounded by a cooling water pipe 17, and the cooling water pipe 17 is provided with cooling liquid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com