High Stability Surround Cutting Process for Stainless Steel Pipe Fittings

A high-stability, high-quality cutting technology, applied in pipe shearing devices, manufacturing tools, shearing devices, etc., can solve the problems of wasting pipe fitting materials, cutting end faces that are difficult to reach flat, and wasting time for operators, so as to avoid waste, The effect of high flatness and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The high stability surround cutting process of stainless steel pipe fittings, the steps are as follows:

[0065] (1) Clamping stage;

[0066] S1: The clamping parts 210 are driven to move away from each other by the first driving part and a space for pipe fittings is reserved, the two cutting mechanisms 310 are driven to move away from each other by the second driving part, and the two pressing mechanisms 320 are driven to move away from each other Allow space for fittings to be inserted;

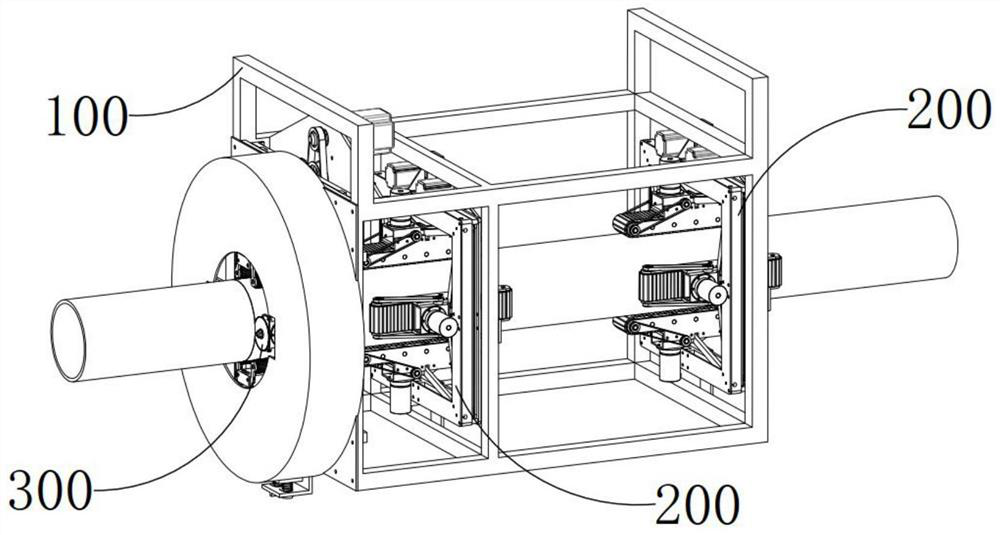

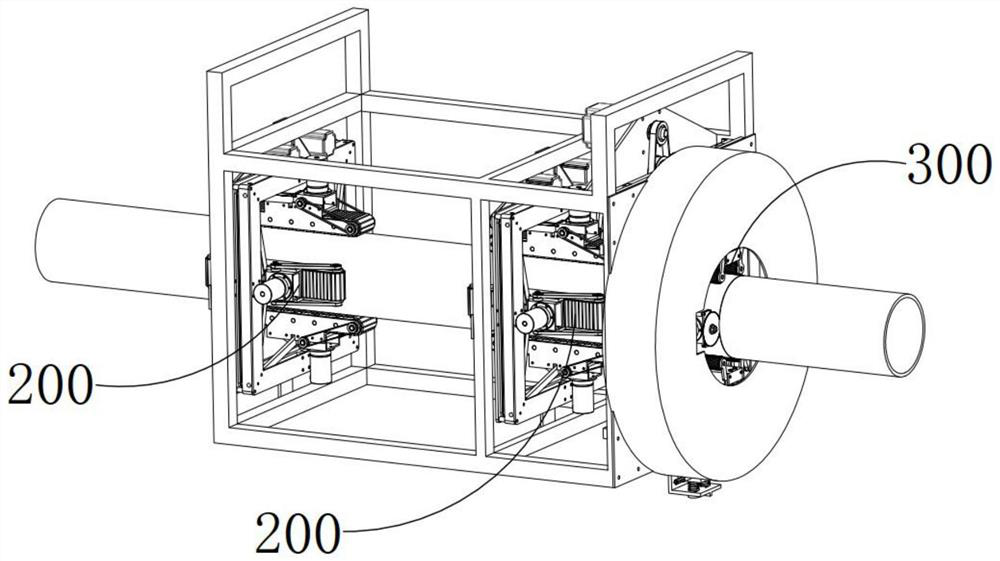

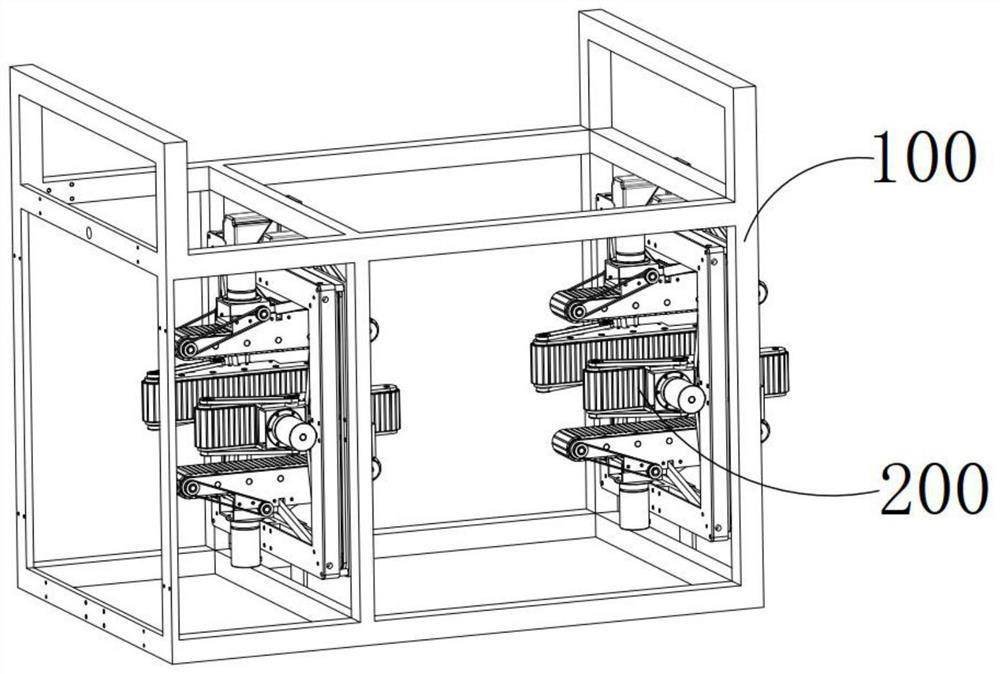

[0067] The clamping part 210 and the box-shaped driving part 220 together constitute the clamping and feeding device 200, and the cutting mechanism 310, the pressing mechanism 320, the driving part 330 and the rotating driving mechanism 340 together constitute the surrounding cutting device 300, the clamping and feeding device 200 is provided with two and is fixedly installed on the mounting frame 100 arranged front and rear, the surrounding cutting device 300 is also fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com