Soil heavy metal layered treatment method

A heavy metal and soil technology, applied in the field of contaminated soil treatment, can solve the problems of shallow treatment depth, reduced treatment effect, uneven distribution of treatment agents, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

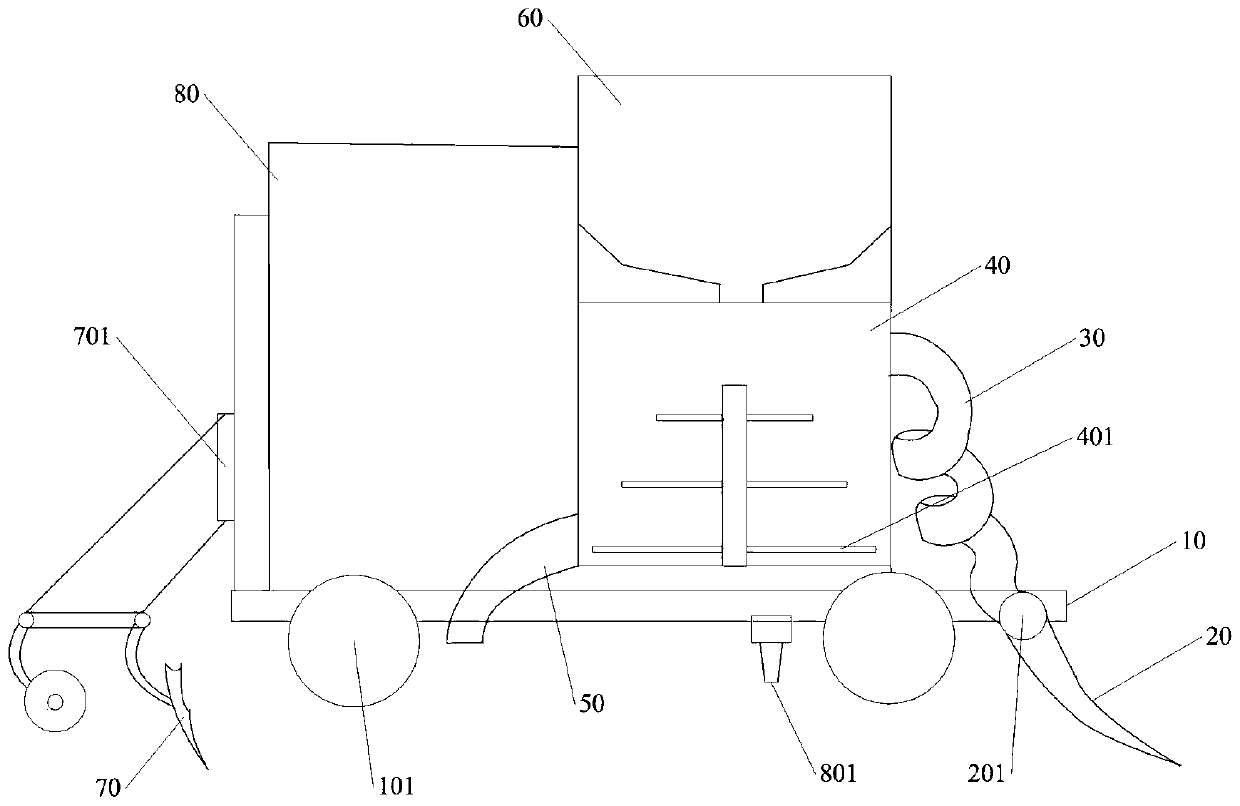

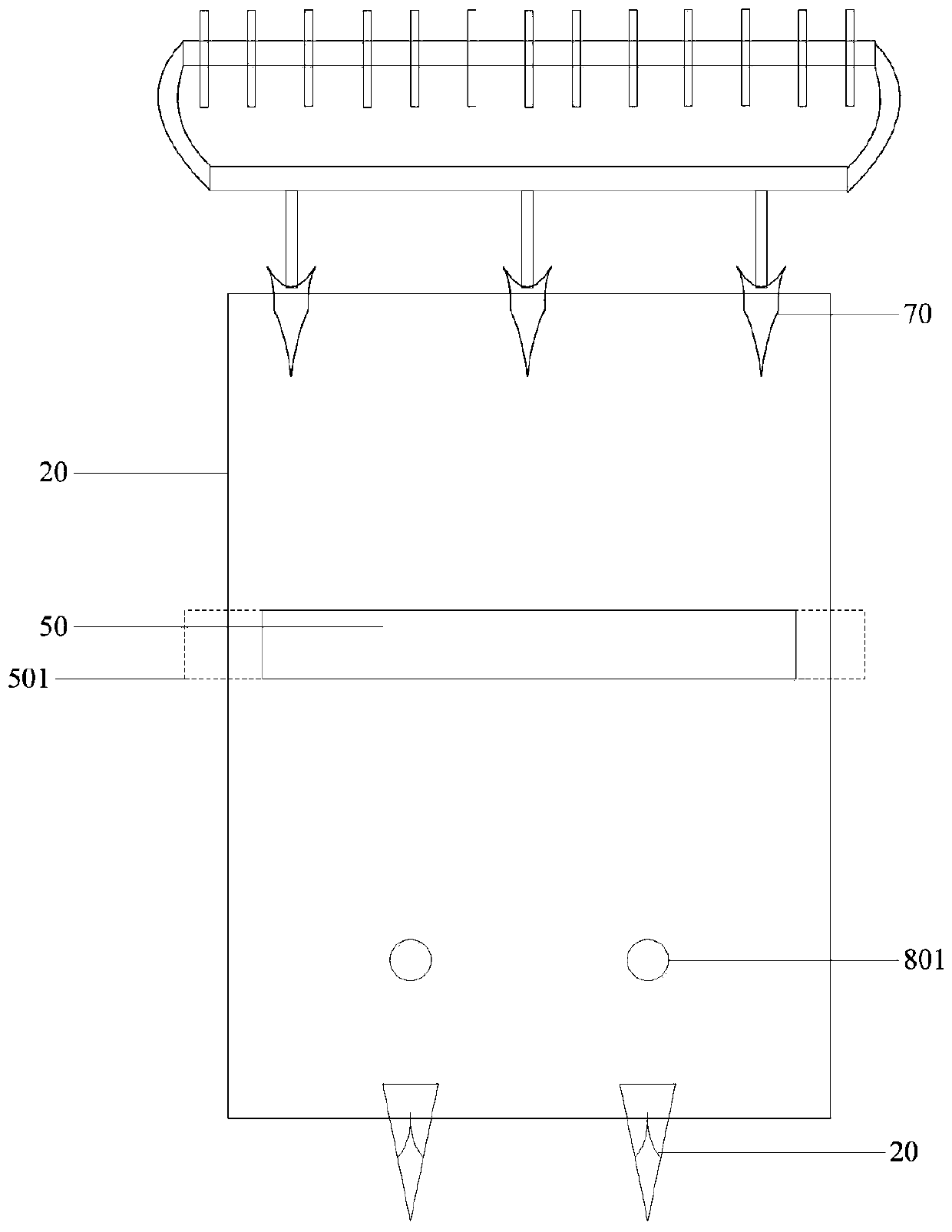

[0039] Such as Figure 2~3As shown, the soil heavy metal stratified management device in the method of the present invention comprises a car body 10; at least two excavating and transporting plows 20, which are arranged side by side and spaced below the car body, and the two excavating and transporting plows are provided with pointed The arc-shaped metal sheet body, and the tail end of the arc-shaped metal sheet body is wound into a cylindrical shape to form a conveying channel in the axial direction of the excavating conveying plow; through the rotating shaft 201, at least two excavating conveying plows are driven upward as a whole Or rotate downwards to adjust the relative height between its tip and the ground; at least two spiral conveying cylinders 30, one end of which is connected to the tail end of the arc-shaped metal sheet body, and the other end of the spiral conveying cylinder is inclined toward the car body. The top is extended; the mixing box 40 is arranged on the ...

Embodiment 2

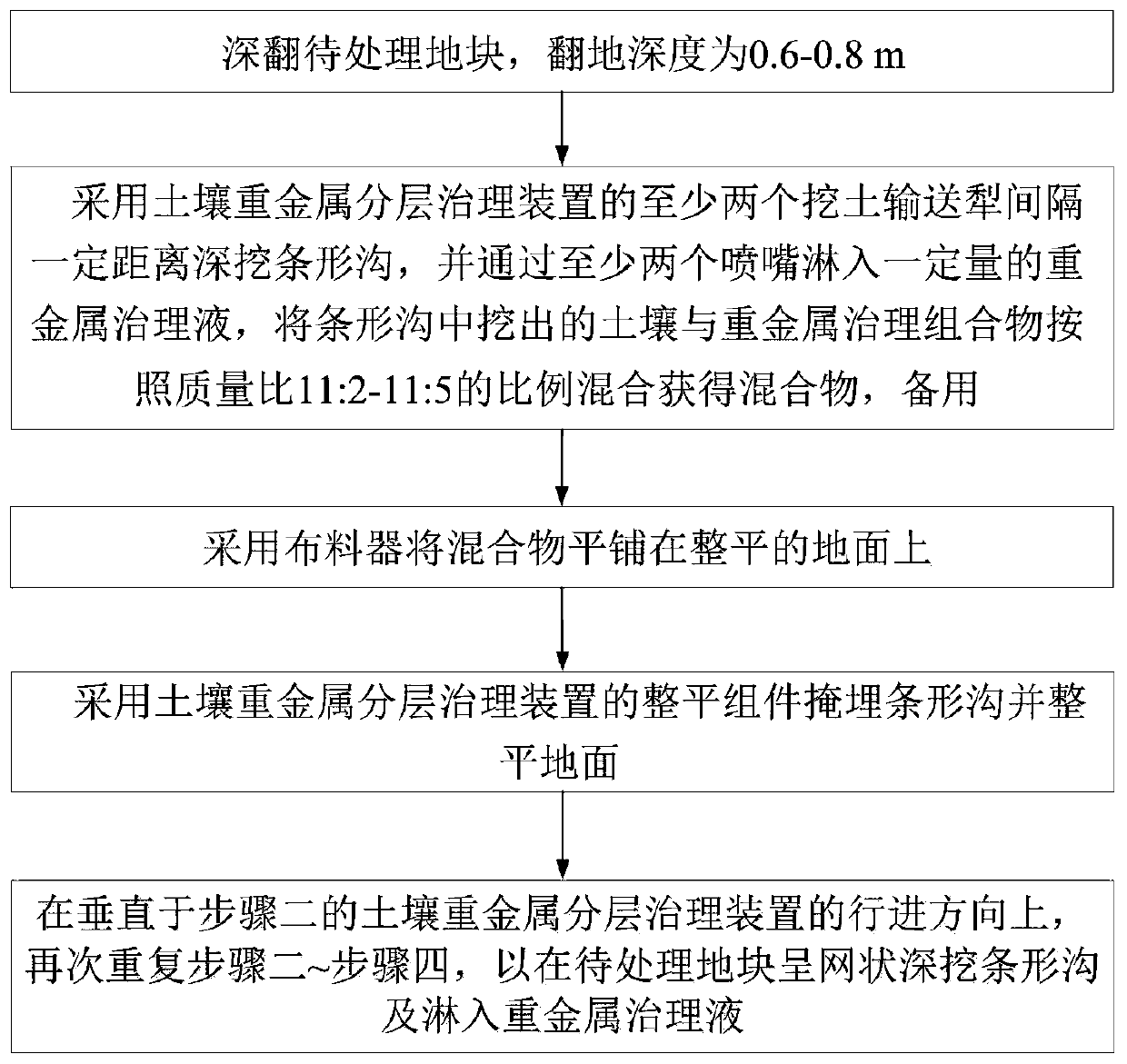

[0049] A method for stratified management of soil heavy metals, comprising the following steps:

[0050] Step 1: Digging the land to be processed deeply, the depth of digging is 0.6m;

[0051] Step 2, using at least two excavating and conveying plows of the soil heavy metal layered treatment device to dig deep strip trenches at a certain distance, and pour a certain amount of heavy metal treatment liquid through at least two nozzles, and remove the excavated soil from the strip trenches. The soil and the heavy metal control composition are mixed according to the ratio of mass ratio 11:2 to obtain a mixture, which is set aside;

[0052] Step 3, using a spreader to spread the mixture on the flat ground;

[0053] Step 4, using the leveling component of the soil heavy metal layered treatment device to bury the strip trench and level the ground;

[0054] Step 5, in the direction of travel perpendicular to the step 2 of the soil heavy metal layered treatment device, repeat steps 2...

Embodiment 3

[0062] A method for stratified management of soil heavy metals, comprising the following steps:

[0063] Step 1, deep digging of the land to be processed, the depth of digging is 0.65-0.7m;

[0064] Step 2, using at least two excavating and conveying plows of the soil heavy metal layered treatment device to dig deep strip trenches at a certain distance, and pour a certain amount of heavy metal treatment liquid through at least two nozzles, and remove the excavated soil from the strip trenches. The soil and the heavy metal control composition are mixed according to the ratio of 11:3 by mass to obtain a mixture, which is set aside;

[0065] Step 3, using a spreader to spread the mixture on the flat ground;

[0066] Step 4, using the leveling component of the soil heavy metal layered treatment device to bury the strip trench and level the ground;

[0067] Step 5, in the direction of travel perpendicular to the step 2 of the soil heavy metal layered treatment device, repeat step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com