Crusher for waste battery recycling

A technology for used batteries and crushers, applied in grain processing and other directions, can solve the problems of shooting workers, worker threats, the existence of harmful substances, etc., and achieve the effect of facilitating sorting and recycling, avoiding debris splashing, and increasing air flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

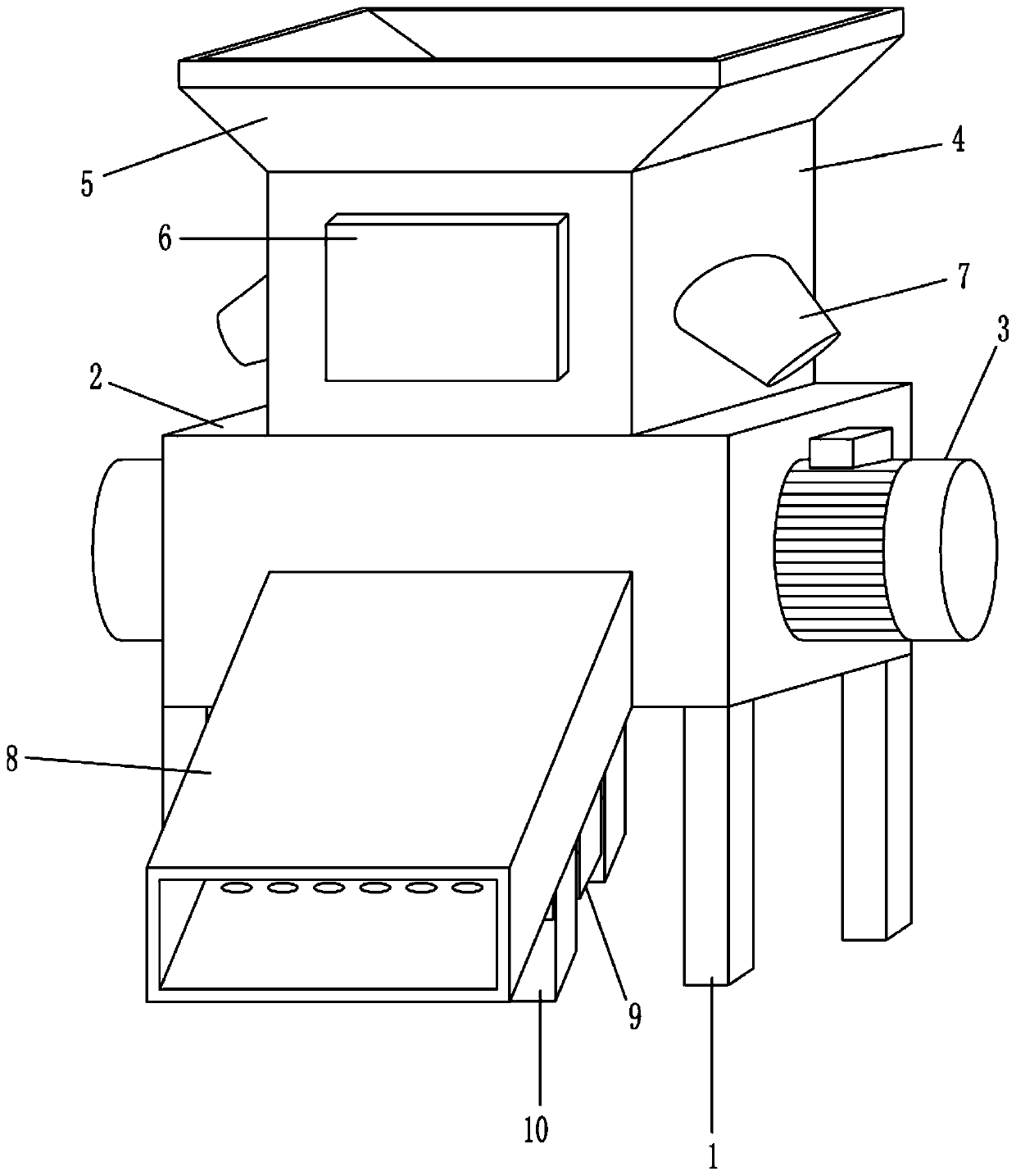

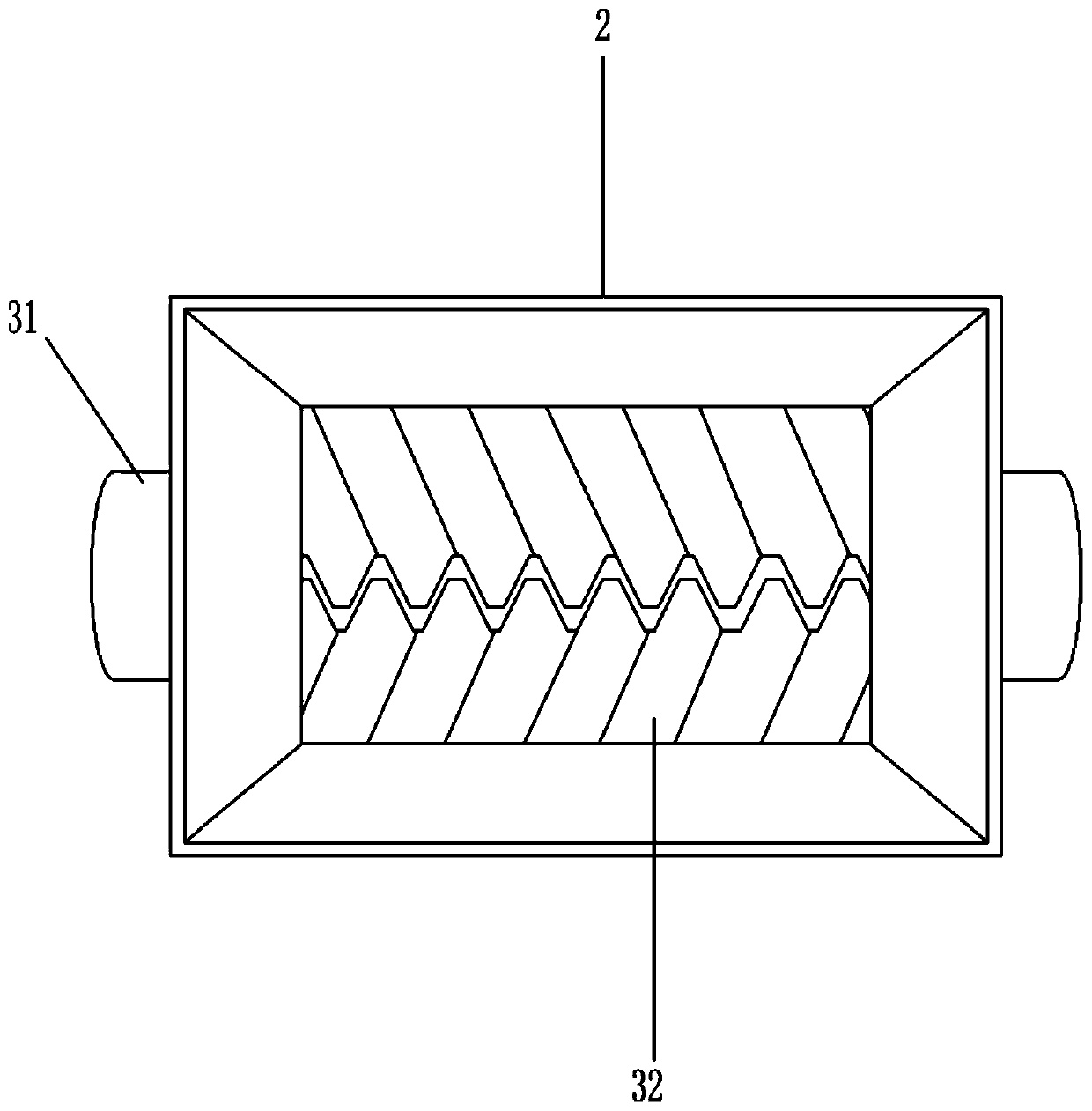

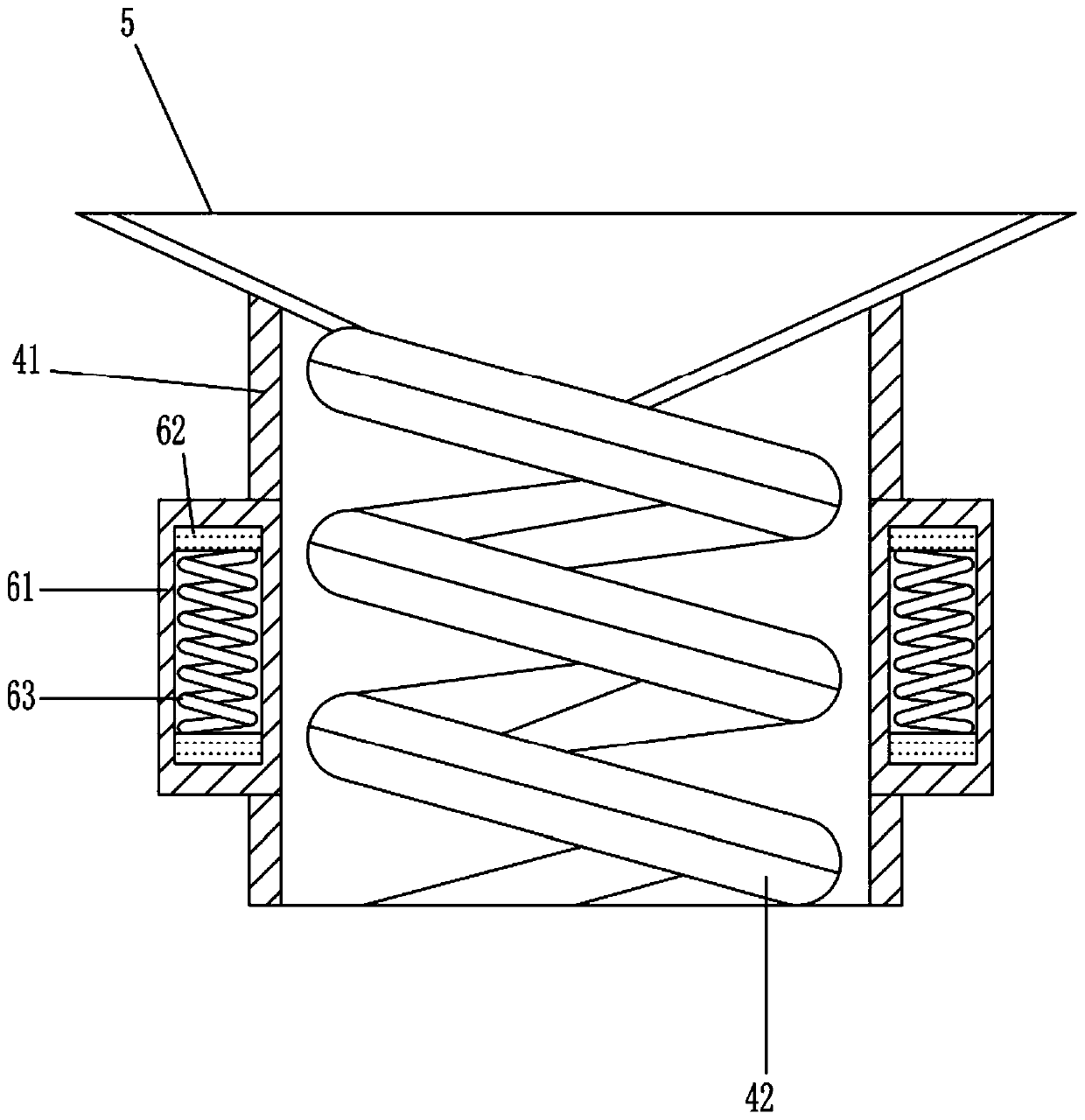

[0030] A crusher for waste battery recycling, such as Figure 1-9 As shown, it includes a support foot 1, a crushing box 2, a driving assembly 3, a feeding assembly 4, a lower hopper 5, a heating part 6, a blowing part 7, a discharge pipe 8, a vibrating part 9 and a collection assembly 10; the crushing box 2 It is fixed on the top of the support foot 1; the driving assembly 3 is fixed on the inner wall of the crushing box 2, and the driving assembly 3 includes a driving motor 31 and a crushing unit 32; The output ends of the two drive motors 31 are sequentially connected by transmission, and the crushing units 32 are meshed with each other; the discharge pipe 8 is fixedly connected to the crushing box 2, and communicates with the inside of the crushing box 2; the feeding assembly 4 is fixed on the top of the crushing box 2, and It communicates with the crushing box 2; the feeding assembly 4 includes a feeding cylinder 41 and a spiral guide rail 42; the feeding cylinder 41 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com