Fertilizer applying equipment for agricultural machinery

A technology for agricultural machinery and equipment, applied in the field of fertilization equipment for agricultural machinery, can solve problems such as affecting the full mixing of soil and fertilizer, and achieve the effects of avoiding clogging, ensuring uniformity, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

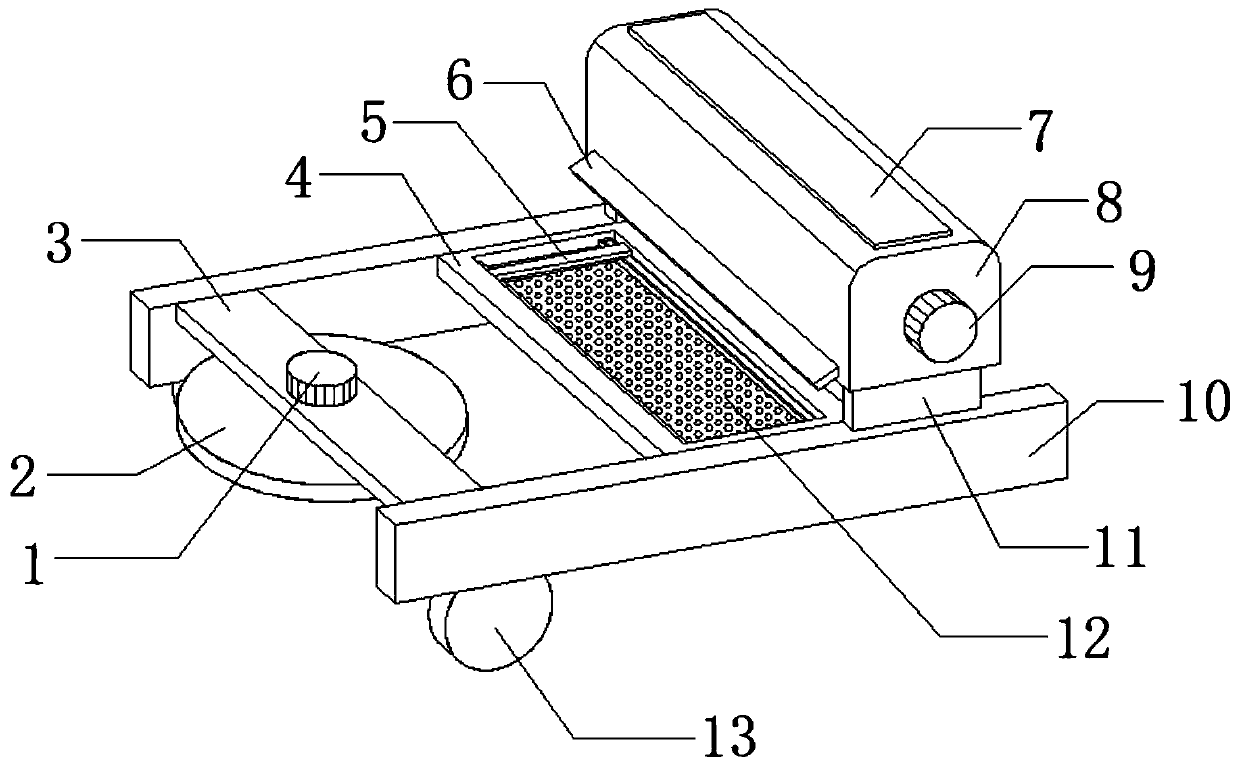

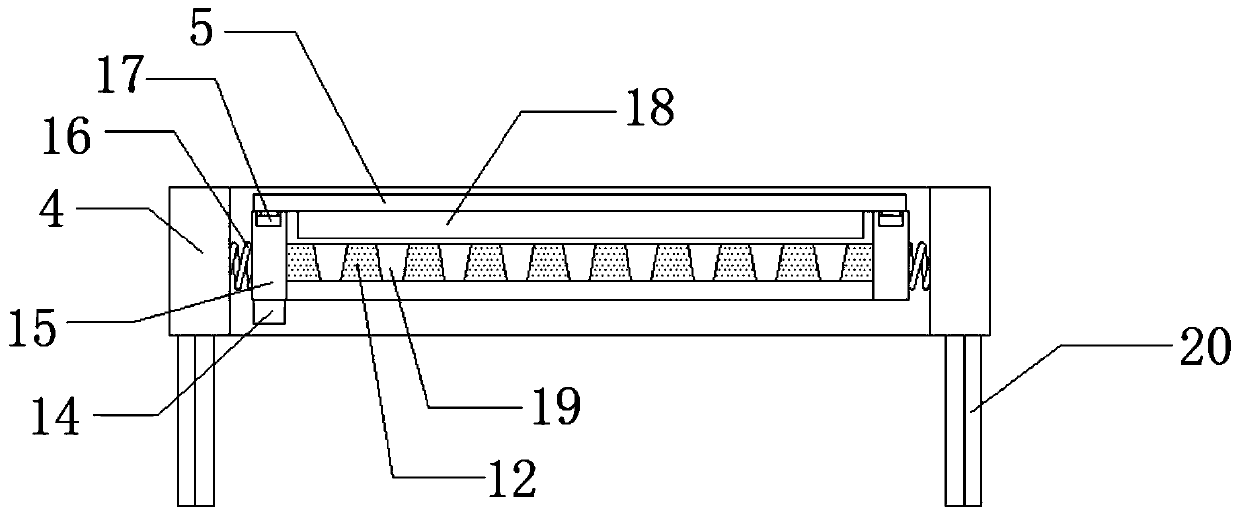

[0032] refer to Figure 1-6, a fertilizing equipment for agricultural machinery, comprising two first mounting plates 10 and two rollers 13, the two rollers 13 are respectively installed on the outer wall of the bottom side of the two first mounting plates 10 by bolts, the two first mounting plates The outer walls on one side of the top of the plate 10 are all connected with a third support plate 11 by bolts, and the outer walls of the top of the two third support plates 11 are connected with the same material storage box 8 by bolts, and the bottom of the side of the material storage box 8 The discharge pipe 6 is connected by bolts, the top outer wall of the material storage box 8 is provided with a feed inlet, and the outer wall on one side of the top of the feed inlet is connected with a feed cover 7 through a hinge, and the two first mounting plates 10 are adjacent The middle outer wall of one end is provided with a first groove, and the inner walls of the two first grooves...

Embodiment 2

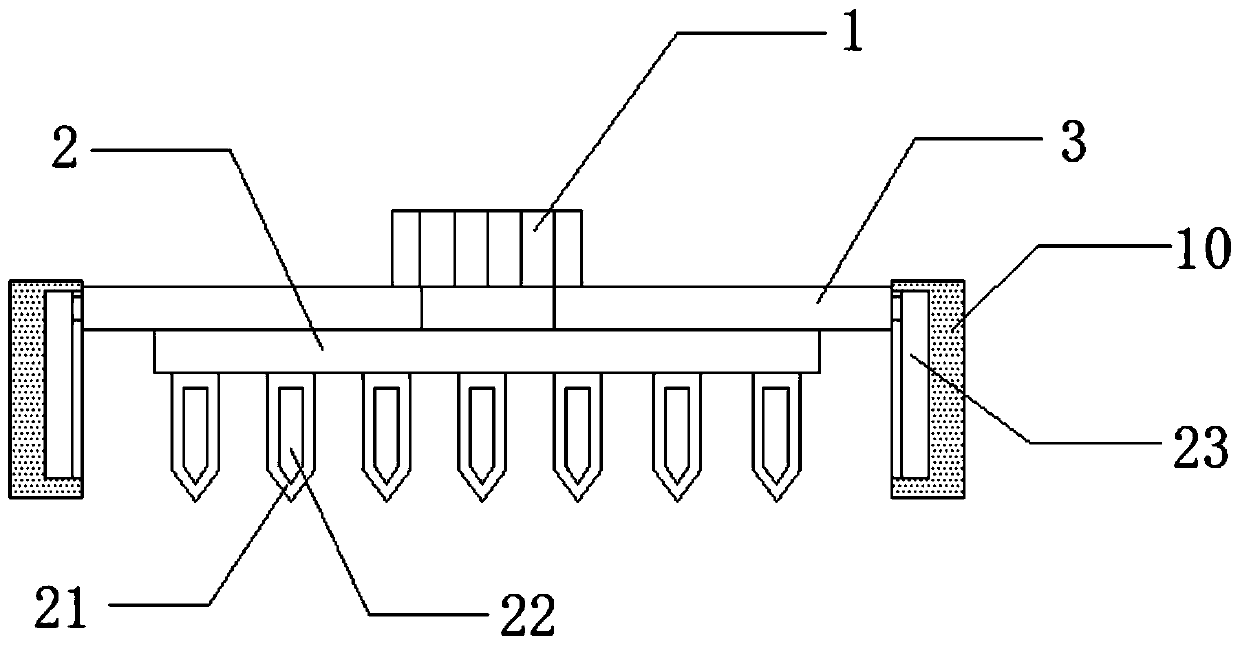

[0042] refer to Figure 1-7 , a fertilizing equipment for agricultural machinery, further comprising a third rotating motor 29 mounted on the outer wall at one end of one of the first mounting plates 10 through bolts, and the output shaft of the third rotating motor is connected with a rotating roller 31 through bolts, and the rotation The outer peripheral wall of the roller 31 is connected with third turning bars 30 distributed in an annular array by bolts, and the cross section of the third turning bars 30 is triangular.

[0043] Working principle: when in use, before fertilization, the third turning motor 29 can drive the turning roller 31 and the third tilling bar 30 to rotate, and then the third turning bar 30 can perform preliminary turning of the soil, which improves the efficiency of soil crushing. Effect, which in turn facilitates the convenience of soil and fertilizer mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com