Dust collection device and method for detecting rupture of filter in dust collection device

A technology of dust collection device and filter, which is applied in chemical instruments and methods, separation methods, exhaust devices, etc., and can solve problems such as filter damage and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

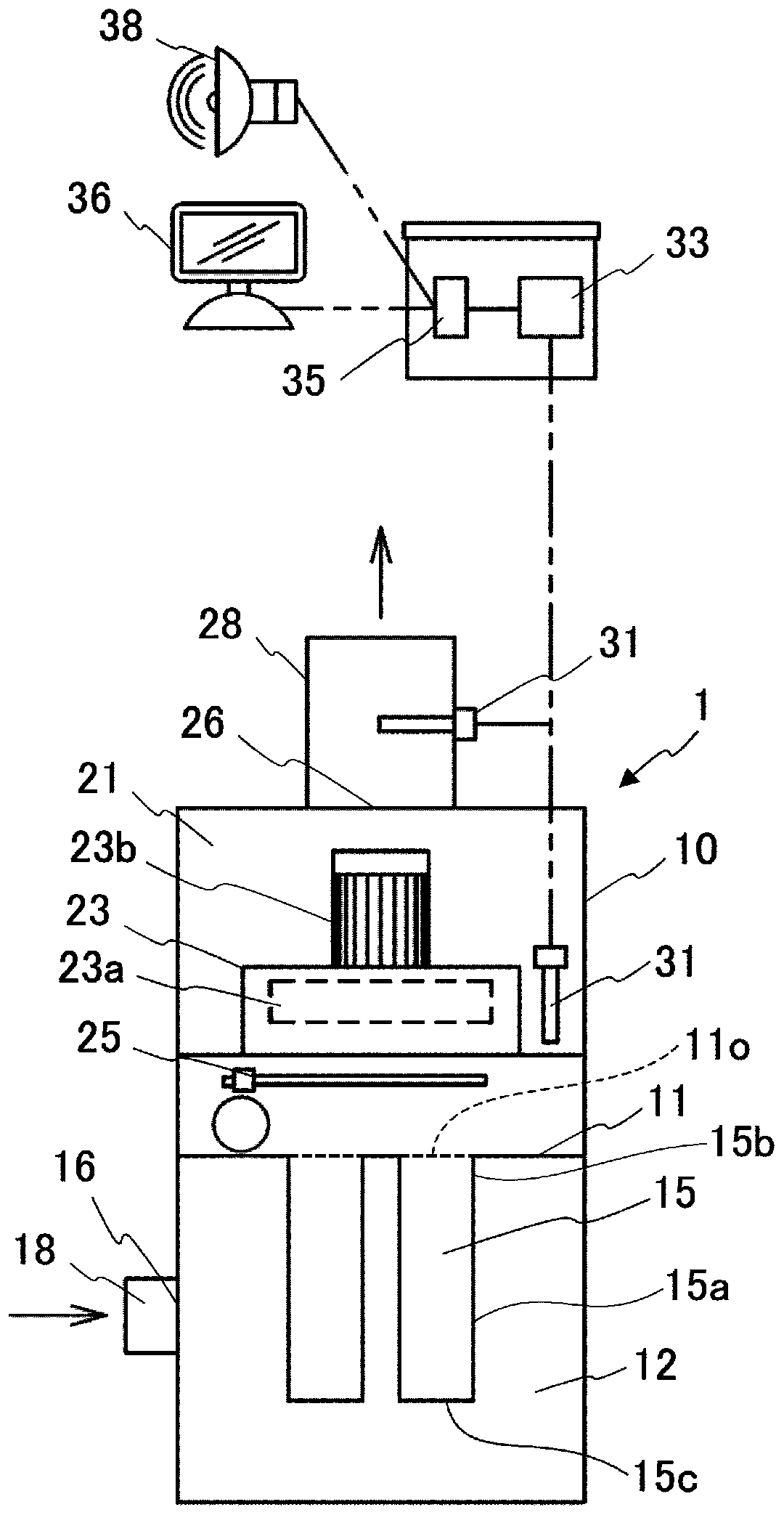

[0027] Hereinafter, the dust collector of the present invention will be described with reference to the drawings.

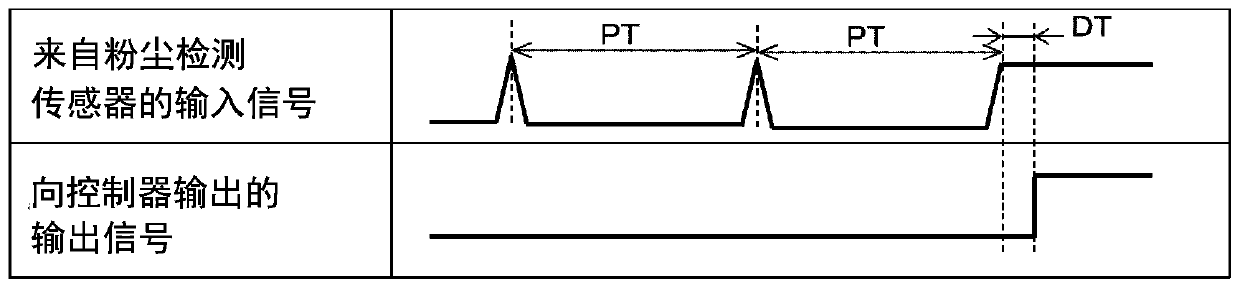

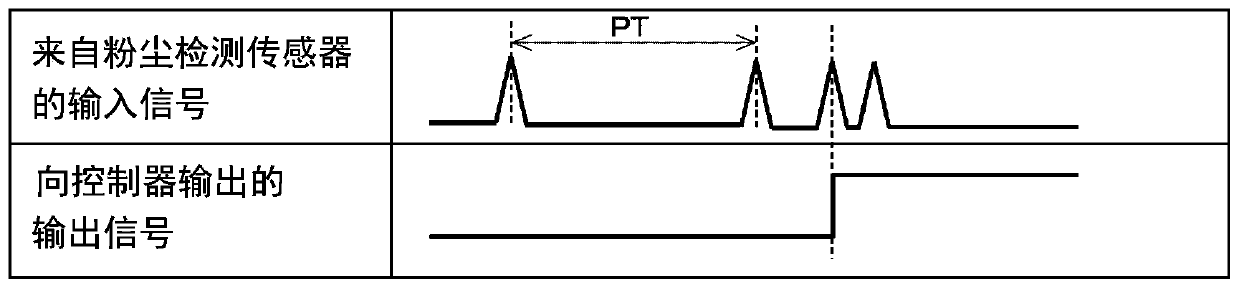

[0028] The dust collecting device of the present embodiment includes: a dust-containing air chamber into which dust-containing air sucked by a blower is introduced; a filter for passing the dust-containing air and separating dust from the dust-containing air; a clean air chamber, which is separated from the dust-containing air chamber by a filter, and the clean air filtered by the filter is introduced into the clean air chamber; and a pulse jet dust removal mechanism, which pulse jet dust removal mechanism The dust attached to the filter is removed at regular time intervals, and the dust collection device includes: a dust detection sensor, which is arranged on the side of the clean air room, and sends a dust detection signal if dust is detected; and a judgment processing unit, which The determination processing unit determines that breakage of the filter has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com