A kind of anti-seepage treatment method for weakly permeable formation

A treatment method and stratum technology, applied in chemical instruments and methods, applications, construction, etc., can solve the problems of reducing the water permeability of sand layers, secondary water leakage, high engineering cost, etc., and meet high-standard anti-seepage requirements, The effect of ensuring the quality of the project and reducing the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] From top to bottom, the Miluo Friendship River embankment consists of backfill, silt and fine sand, fine sand with pebbles, argillaceous siltstone, etc., among which the permeability coefficient of silt and fine sand is 5~15 Lu, and fine sand with pebbles The permeability coefficient of the formation is 10~20Lu, which belongs to the weakly permeable formation, and the depth range is 7~15m. The design requirement is that after the formation is treated, the permeability coefficient is less than 5Lu.

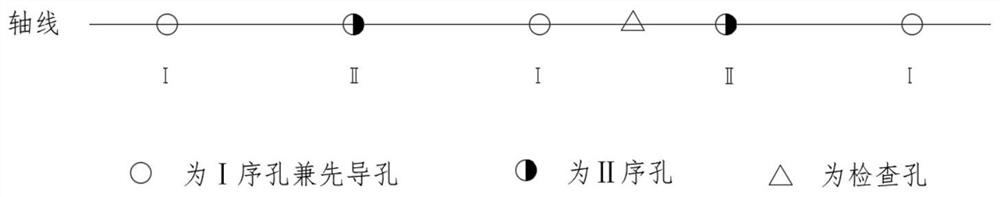

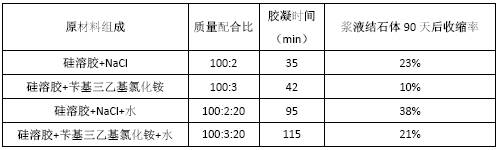

[0030] The anti-seepage treatment method for weakly permeable strata of the present invention is to use double rows of holes to carry out curtain grouting, each row is divided into two sequences of construction, the first sequence of holes adopts the method of pulse pouring plastic grout to reduce the pore volume of the pores; the second sequence of holes The silica sol nano-slurry is used for permeation and curing treatment to achieve the purpose of forming better anti-seep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com