PE protective film

A technology of protective film and protective layer, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, adhesive additive, etc. To achieve the effect of suppressing the retraction problem, increasing the connection strength, and balancing the properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

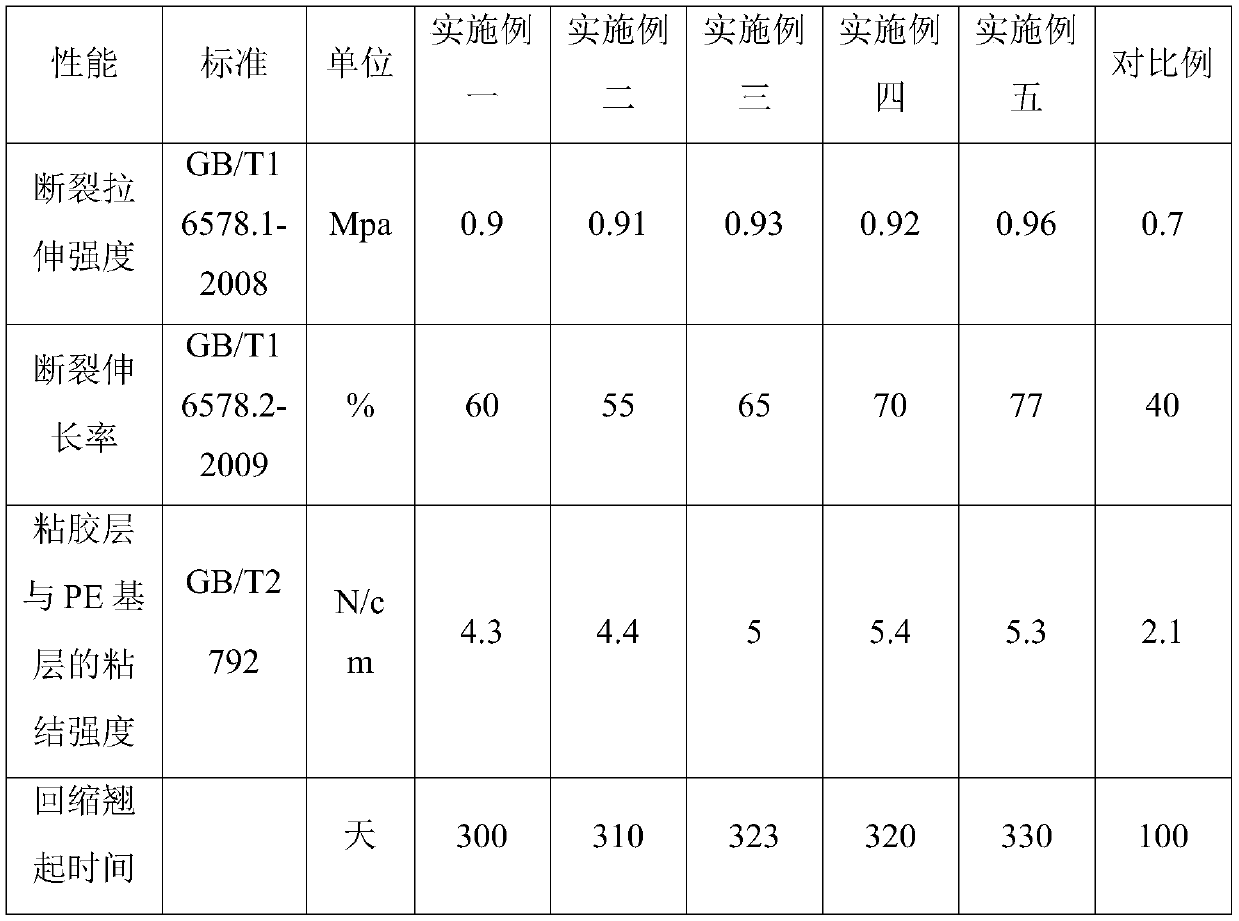

Examples

Embodiment 1

[0037] A PE protective film, the thickness ratio of the adhesive layer, the connection layer, the PE base layer, the anti-retraction layer and the protective layer is: 1:1:3:1:1.

[0038] in:

[0039] The raw materials of the PE base layer include the following parts by weight: 35 parts of low-density polyethylene with a density of 0.92 g / cubic centimeter, and 12 parts of high-density polyethylene with a density of 0.94 g / cubic centimeter;

[0040] The raw materials of the anti-retraction layer include the following parts by weight: 30 parts of thermosetting phenolic resin, 12 parts of penetrating agent;

[0041] The raw materials of the linking layer include the following parts by weight: 12 parts of low-density polyethylene with a density of 0.91 g / cubic centimeter, and 5-2 parts of crosslinking agent;

[0042] The raw materials of the adhesive layer include the following parts by weight: 23 parts of silicone pressure-sensitive adhesive (SH-916A), 12 parts of anti-aging age...

Embodiment 2

[0055] A PE protective film, the thickness ratio of the adhesive layer, the connection layer, the PE base layer, the anti-retraction layer and the protective layer is: 1:1:4:2:1.

[0056] in:

[0057] The raw materials of the PE base layer include the following parts by weight: 40 parts of low-density polyethylene with a density of 0.922 g / cubic centimeter, and 15 parts of high-density polyethylene with a density of 0.942 g / cubic centimeter;

[0058] The raw materials of the anti-retraction layer include the following parts by weight: 32 parts of thermosetting phenolic resin, 15 parts of penetrating agent;

[0059] The raw materials of the linking layer include the following parts by weight: 15 parts of low-density polyethylene with a density of 0.913 g / cubic centimeter, and 8 parts of crosslinking agent;

[0060] The raw materials of the adhesive layer include the following parts by weight: 30 parts of silicone pressure-sensitive adhesive (SH-916A), 15 parts of anti-aging ag...

Embodiment 3

[0073] A PE protective film, the thickness ratio of the adhesive layer, the connection layer, the PE base layer, the anti-retraction layer and the protective layer is: 2:1:4:2:1.

[0074] in:

[0075] The raw materials of the PE base layer include the following parts by weight: 40 parts of low-density polyethylene with a density of 0.925 g / cubic centimeter, and 25 parts of high-density polyethylene with a density of 0.945 g / cubic centimeter;

[0076] The raw materials of the anti-retraction layer include the following parts by weight: 36 parts of thermosetting phenolic resin, 20 parts of penetrating agent;

[0077] The raw materials of the linking layer include the following parts by weight: 20 parts of low-density polyethylene with a density of 0.915 g / cubic centimeter, and 10 parts of crosslinking agent;

[0078] The raw materials of the adhesive layer include the following parts by weight: 30 parts of silicone pressure-sensitive adhesive (SH-916A), 20 parts of anti-aging a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com