Black-odor riverway ecological transformation method utilizing building rubbish reclaimed materials and sludge

A technology for construction waste and recycled materials, applied in the fields of botanical equipment and methods, construction, artificial waterways, etc., can solve the problems of sacrificing the water environment and waste of resources, not in line with the basic concept of sustainable development, etc., to save management costs, The channel has strong anti-scour ability and the effect of reducing engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Level the slope protection slope of the black and odorous river, remove all rocks, broken mud, miscellaneous plants, and garbage, the slope ratio is 1:0.75, the slope is Class I, and the height is 4m. Dredging the river channel silt, removing the silt and leveling the bottom of the canal.

[0036] (2) The fine aggregate (particle size ≤ 2.36mm) and the solidified sludge after construction waste are screened are uniformly mixed by a mixer, and the mixing time is 180 seconds. After mixing evenly, polyacrylamide, carboxymethyl Cellulose sodium water retaining agent is modified by composite intercalation through aqueous solution polymerization. After the composite anti-seepage material is prepared, it is laid on the river slope protection and the bottom of the channel with a thickness of 8cm to form a composite anti-seepage layer for the river.

[0037] (3) Select the construction waste coarse aggregate to prepare a rectangular prefabricated porous concrete block with a...

Embodiment 2

[0047] (1) Level the slope protection slope of the black and odorous river, remove all rocks, broken mud, miscellaneous plants, and garbage, the slope ratio is 1:1.25, the slope is a first-class structure, and the vertical height is 3m. Dredging the black and odorous silt, removing the silt and leveling the canal bottom.

[0048] (2) The fine aggregate (particle size ≤ 2.36mm) and the solidified sludge after construction waste are screened are uniformly mixed by a mixer, and the mixing time is 180 seconds. After mixing evenly, polyacrylamide, carboxymethyl Cellulose sodium water retaining agent is modified by composite intercalation through aqueous solution polymerization. After the composite anti-seepage material is prepared, it is laid on the river slope protection and the bottom of the channel with a thickness of 8cm to form a composite anti-seepage layer for the river.

[0049] (3) Select construction waste coarse aggregate to prepare a regular hexagonal prefabricated poro...

Embodiment 3

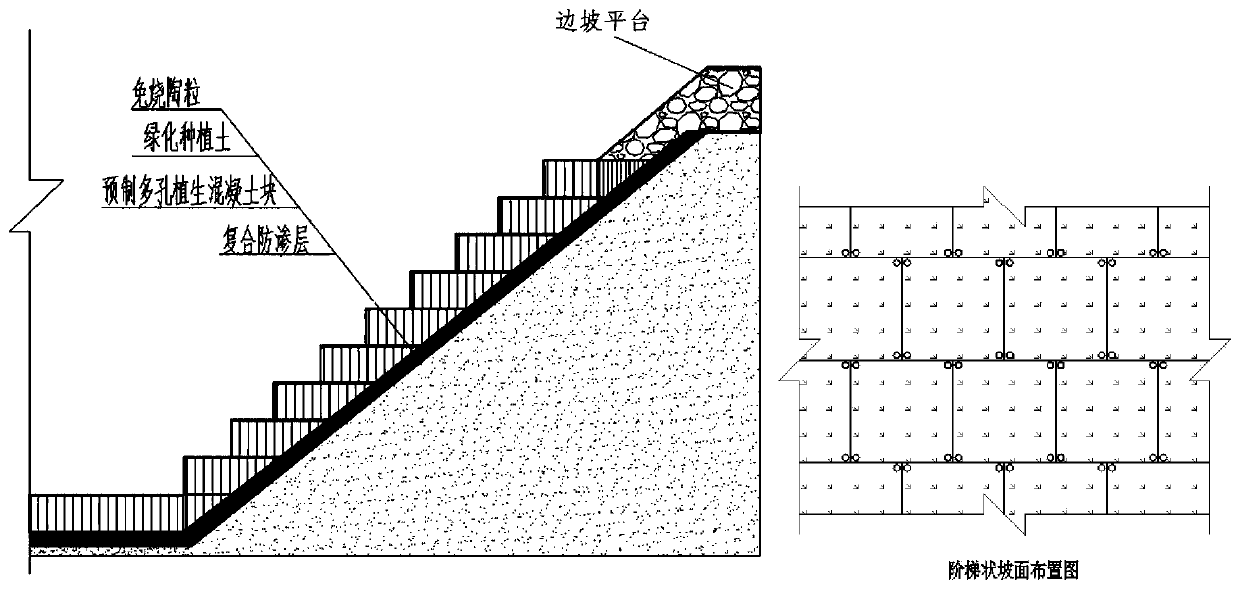

[0058] (1) Level the slope protection slope of the black and odorous river, remove all rocks, broken mud, miscellaneous plants, and garbage, and build a stepped foundation along the slope with a slope ratio of 1:1.25 and a vertical height of 3m. Dredging the river channel silt, removing the silt and leveling the bottom of the canal. For slope drainage ditch construction, excavate a rectangular trench with a width of 20cm and a depth of 20cm.

[0059] (2) The fine aggregate (particle size ≤ 2.36mm) and the solidified sludge after construction waste are screened are uniformly mixed by a mixer, and the mixing time is 180 seconds. After mixing evenly, polyacrylamide, carboxymethyl Cellulose sodium water retaining agent is modified by composite intercalation through aqueous solution polymerization. After the composite anti-seepage material is prepared, it is laid on the foundation of river channel slope protection and channel bottom with a thickness of 8cm to form a composite anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com