Collapsible loess composite grouting material as well as preparation method and application thereof

A technology of collapsible loess and grouting materials, which is applied in soil protection, construction, and infrastructure engineering, etc. It can solve the problems of inaccurate control of grout solidification time, shortened service life of grouting pipes, and high destructiveness of grouting pipes, etc. problem, to achieve the effect of easy adjustment of setting time, easy setting time, and improved water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

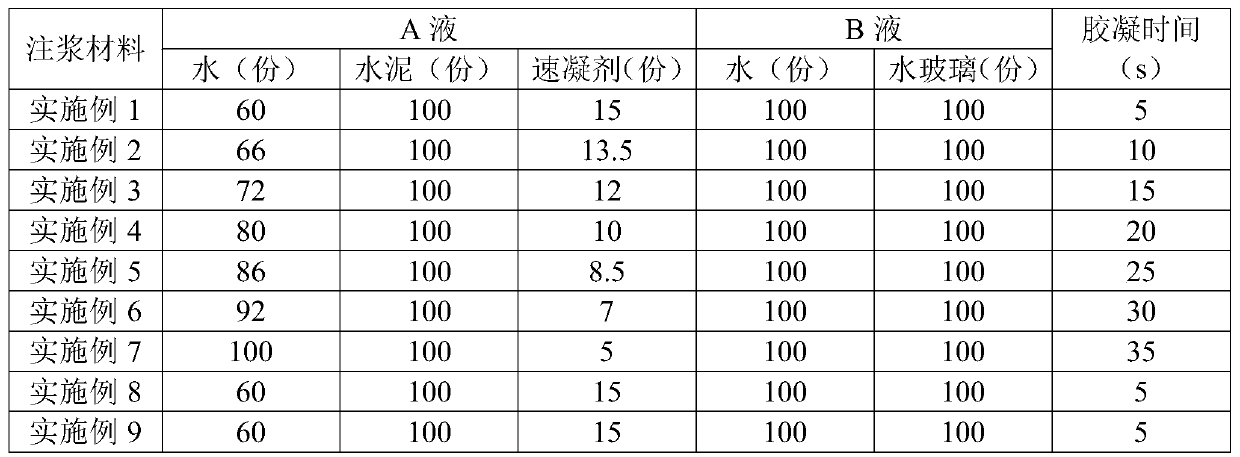

[0031] A collapsible loess composite grouting material, the preparation method includes the following steps:

[0032] S1, preparation of liquid A: fully stir 60-100 parts of water and 100 parts of cement to form a cement single slurry, and then mix 5-15 parts of quick-setting agent into the cement single slurry to form A liquid, wherein, The cement is 42.5 ordinary Portland cement, and the quick-setting agent is calcium hydroxide;

[0033] S2, preparation of liquid B: fully stir 100 parts of water and 100 parts of water glass to form liquid B, wherein the concentration of water glass is 40 degrees Baume, and the modulus is 2.8-3.2;

[0034] S3, when collapsible loess composite grouting material is required, mix liquid A and liquid B.

[0035] The difference between Examples 2-7 and Example 1 is that the component distribution ratios in liquid A and B are different; the difference between Example 8 and Example 1 is that the cement is sulphoaluminate cement, and the quick-setti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com