VAD blowtorch cleaning device and cleaning method

A cleaning device and blowtorch technology, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as difficult cleaning of blowtorch, low degree of automation, broken blowtorch interface, etc., to achieve The effect of reducing the number of disassembly and assembly of pipelines, high degree of automation, and slowing down the scaling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0048] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

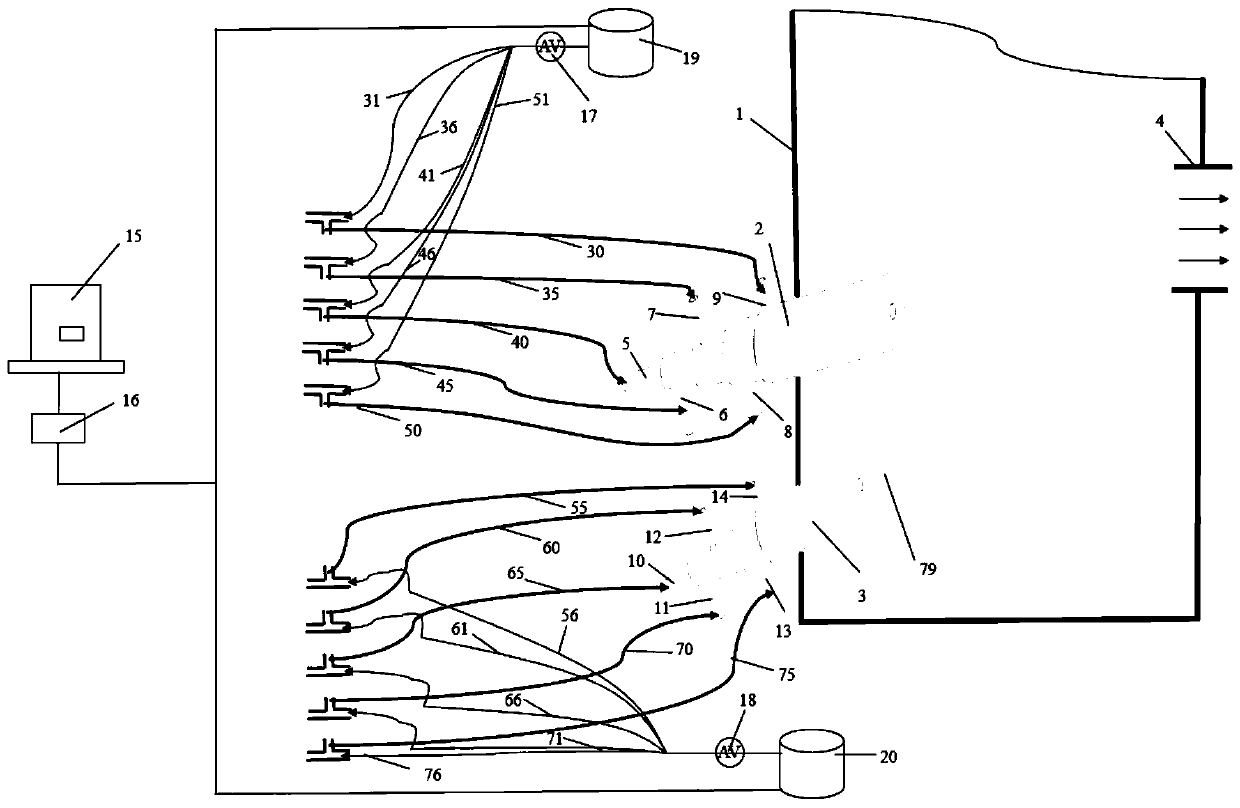

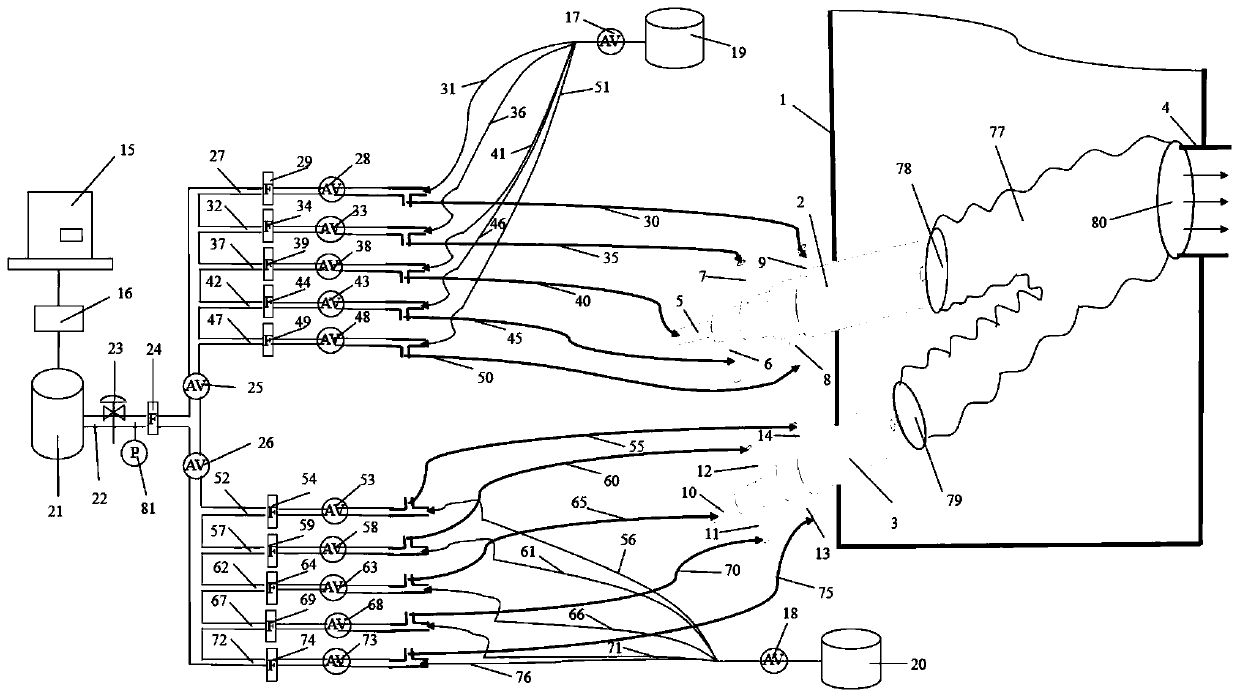

[0049] The present embodiment provides a VAD blowtorch cleaning device, comprising:

[0050] A sweeping gas supply device (specifically, a sweeping gas supply cabinet 21) is used to generate and discharge gas for blowtorch cleaning;

[0051] The intake pipeline switching mechanism (specifically, the three-way pipe and the first to fourteenth automatic valves) has two intake ports and one outlet port, which is used to select and switch one of the two intake ports to open and close. Another pipeline; one of the intake ends of the intake pipeline switching mechanism is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com