Reciprocating type coil winding device

A winding device, reciprocating technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve problems such as affecting the workpiece, tedious operation of replacing the reciprocating screw, easy installation and fixation, etc. The effect of reducing scrap rate, increasing quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

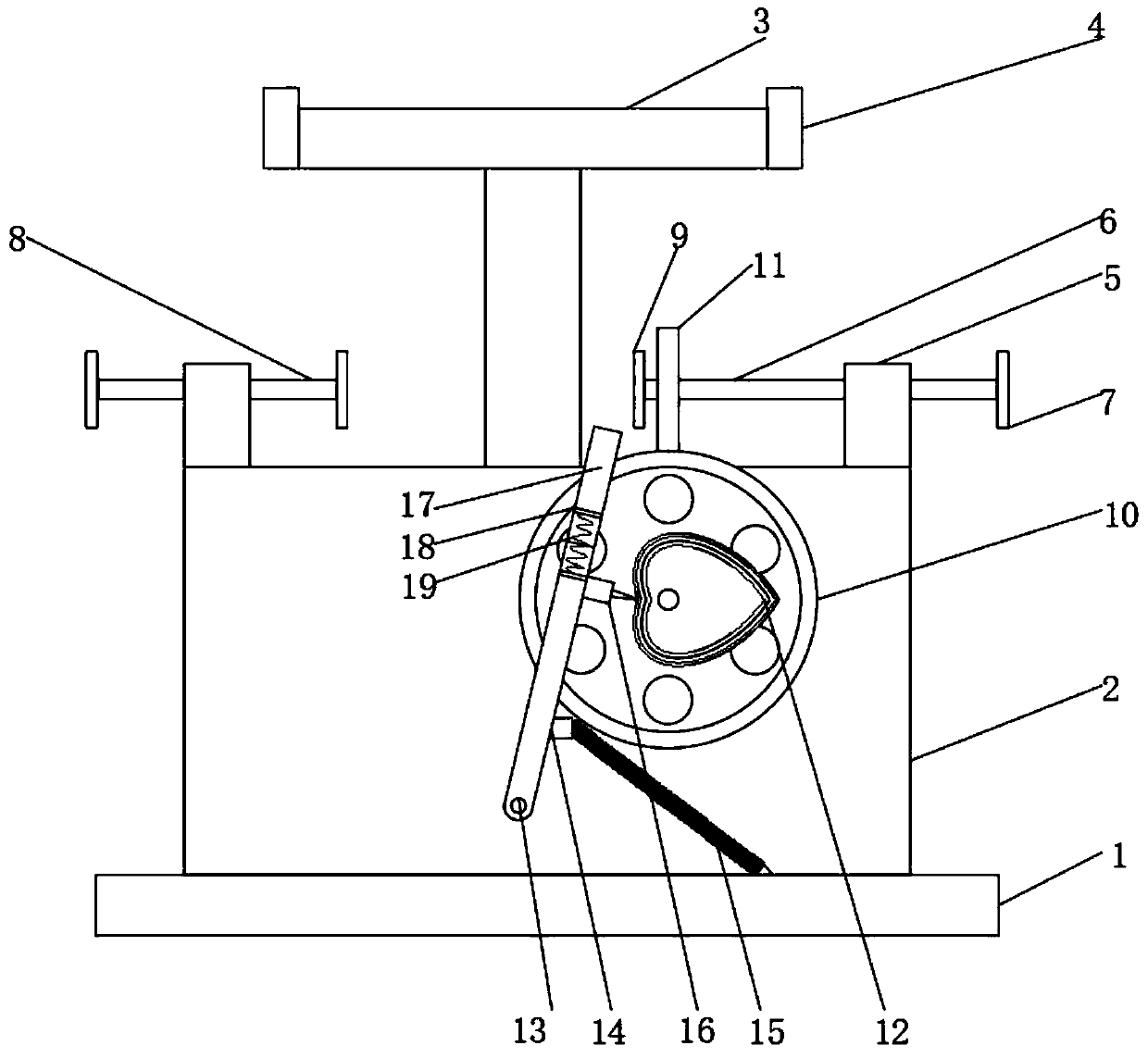

Embodiment 1

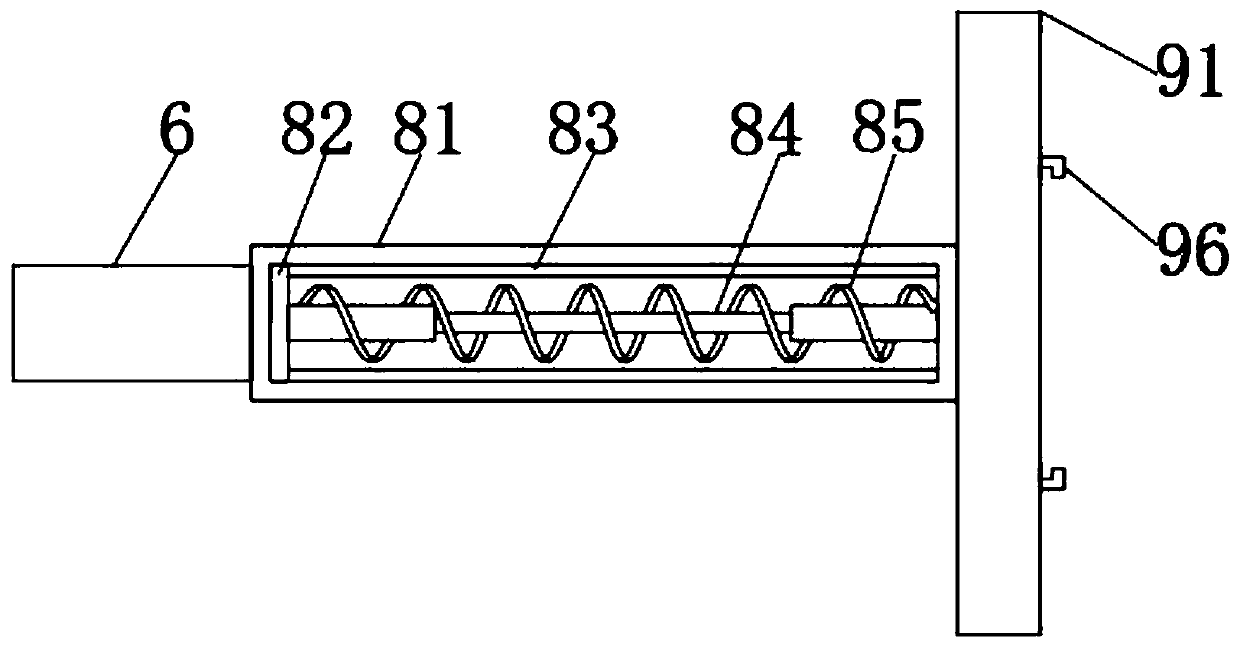

[0036] The adjustable rod 8 includes a hollow cylindrical rod 81, which is sleeved with a slide seat 82, and the upper and lower sides of the inner wall of the hollow cylindrical rod 81 are fixedly connected with slide rails 83, and the slide seat 82 slides on the two slide rails 83 , one side of the sliding seat 82 is elastically connected to one side of the inner wall of the hollow cylindrical rod 81;

[0037] When clamping the workpiece, first place one end of the workpiece on the clamping device 9 on the right side of the adjustable rod 8, move the workpiece to the left, and the clamping device 9 on the left side can move, so that when the right side of the workpiece and the right side The clamping device 9 is fixed after being contacted. This operation and installation process is simple, and under the action of elasticity, it can ensure the stability of workpiece clamping, and it can also be used for workpieces of different lengths, and the scope of use is wider.

Embodiment 2

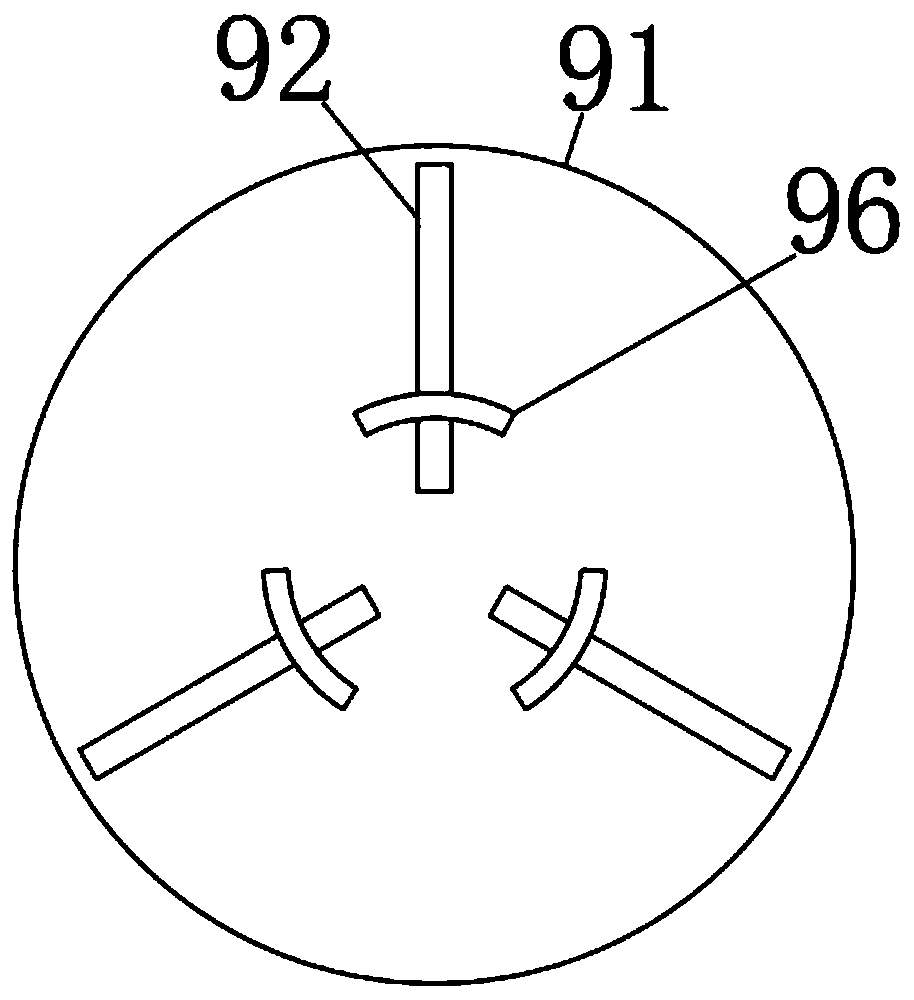

[0039] The clamping device 9 includes a clamping disc 91, one side of the clamping disc 91 is inlaid with three spring sleeves 92, the three spring sleeves 92 are equidistantly arranged, the angle between the intersection points of the extension lines of the three spring sleeves 92 is 120 degrees, and the spring sleeve 92 One side of the inner wall is elastically connected with a movable block 93, and one side of the movable block 93 is fixedly connected with an arc-shaped holder 96. When in use, the three arc-shaped holders 96 can clamp the workpiece tightly, thus ensuring the safety of the workpiece during winding. And stable, and according to the moving range of the arc-shaped clamping seat 96, it is also possible to increase the clamping of different workpieces.

[0040] In order to ensure that the winding rod 17 on the top of the swing rod 14 is in the winding process, along with the increase of the number of coils, the top of the winding rod 17 is prevented from contactin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com