Integrated automobile hub bearing based on fiber bragg grating sensing and manufacturing method of integrated automobile hub bearing

A technology of fiber gratings and automobile hubs, which is applied in the direction of transmitting sensing components, converting sensor outputs, and measuring devices using optical devices, which can solve problems that cannot meet actual needs, and cannot realize the integration of bearing sensors and separate operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

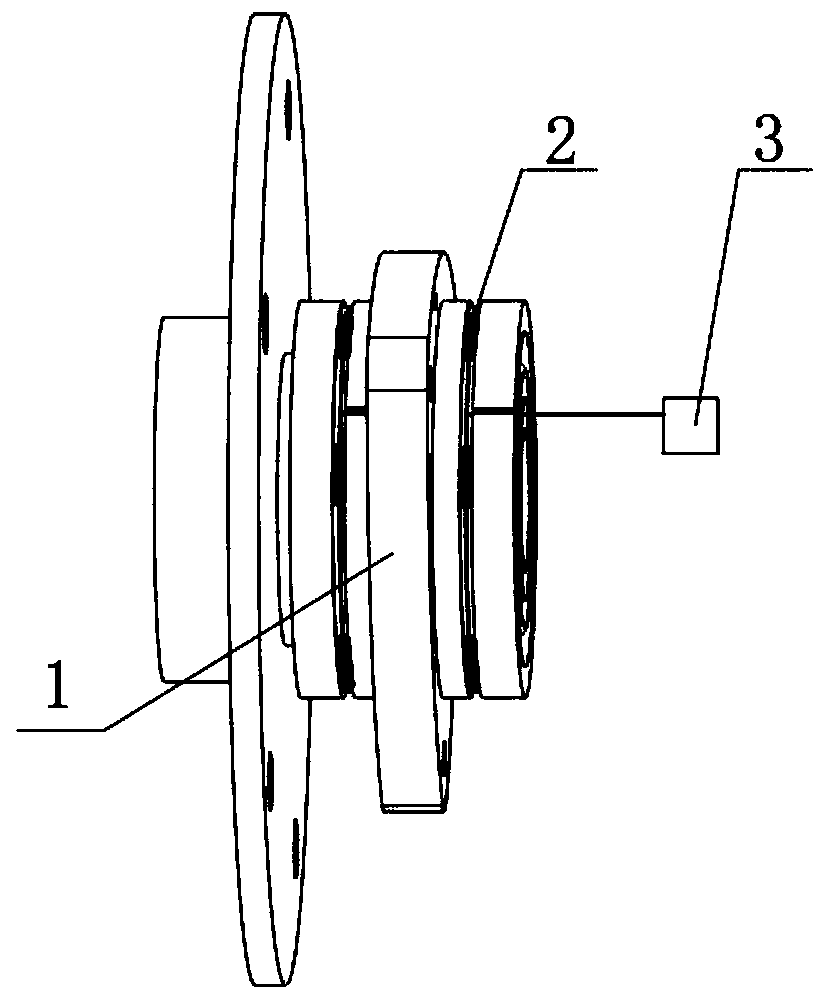

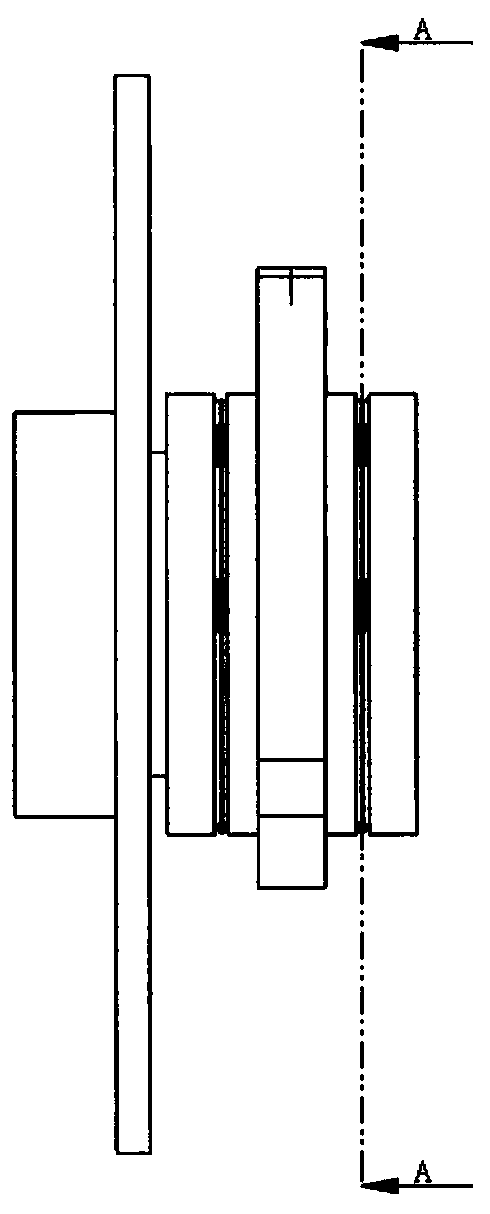

[0058] Such as figure 1 As shown, a sensor-integrated automobile wheel bearing in this embodiment includes an automobile wheel bearing 1 , a fiber grating sensing system 2 and a fiber grating demodulator 3 . The automobile hub bearing 1 is a third-generation automobile hub bearing with a double-row structure. The fiber grating sensing system 2 is installed and fixed on the hub bearing 1 to monitor the temperature and strain state of the outer ring 11 of the automobile hub bearing, and the fiber grating is demodulated The instrument 3 is connected to the fiber grating sensing system 21 for displaying test data.

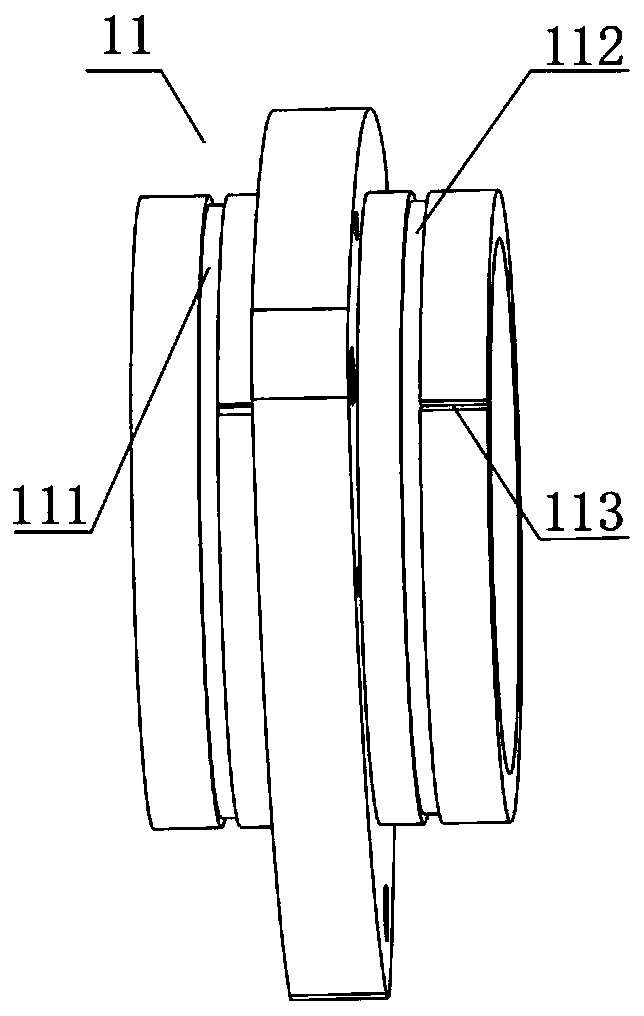

[0059] Such as figure 2 As shown, the automobile hub bearing 1 includes an automobile hub bearing outer ring 11, an inner ring, a cage and rollers, the hub bearing is a double-row structure, and the automobile hub bearing outer ring 11 is a flange structure, and on the outer surface An annular groove and a wire outlet slot are provided, and the annular grooves have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com