Production and installation method for outdoor multi-specialty prefabricated pressure pipeline groups

A technology for pressure pipelines and installation methods, which is applied to pipeline supports, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., and can solve problems such as long construction period, difficult construction, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

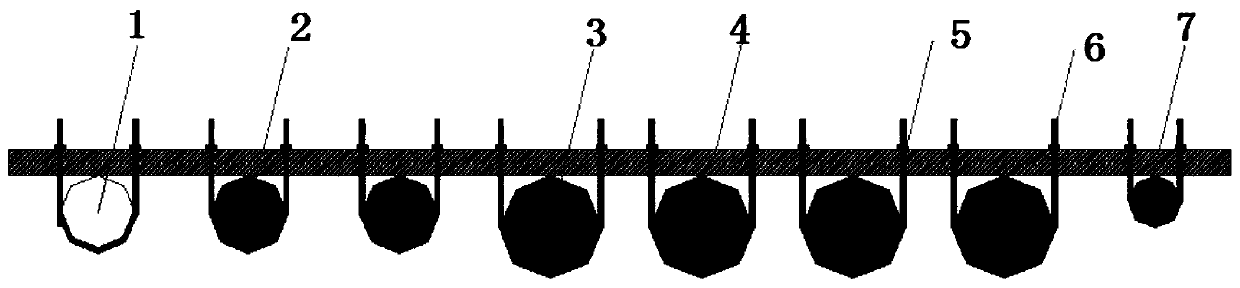

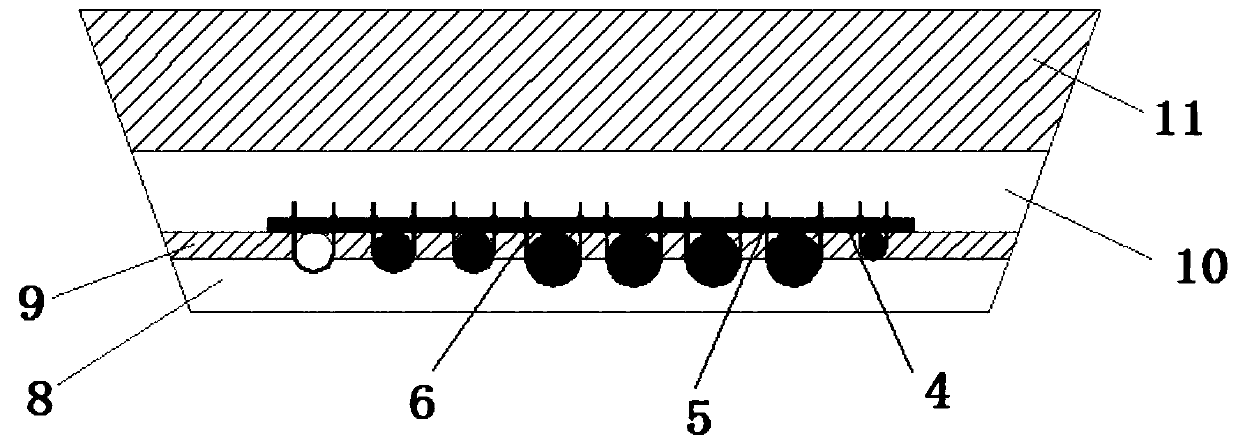

[0028] Such as Figure 1 to Figure 3 As shown, an outdoor multi-specialty prefabricated pressure pipeline group production and installation method includes the following specific steps:

[0029] Step 1: After integrating the professional drawings of outdoor water pipe 3, fire pipe 2, landscape sprinkler pipe 7 and gas pipe 1 through Revit software modeling and integration, conduct collision inspection and find out the collision points, optimize the space layout, and obtain a design that matches the site virtualization model;

[0030] Step 2: Revit software splits the pressure pipe network in an area into a module group according to the pipe length, forming multiple prefabricated pressure pipe groups;

[0031] Step 3: The revit software exports the information of the prefabricated pressure pipe group, such as diameter, length, material, heat preservation and anticorrosion, etc., and the above information is fed back to the pipe processing plant;

[0032] Step 4: The factory p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com