Thrust plate of axial plunger pump

A technology of axial piston pump and distribution plate, which is applied to piston pumps, pumps, multi-cylinder pumps, etc., can solve the problems of high noise and achieve the effects of high working pressure, noise reduction and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

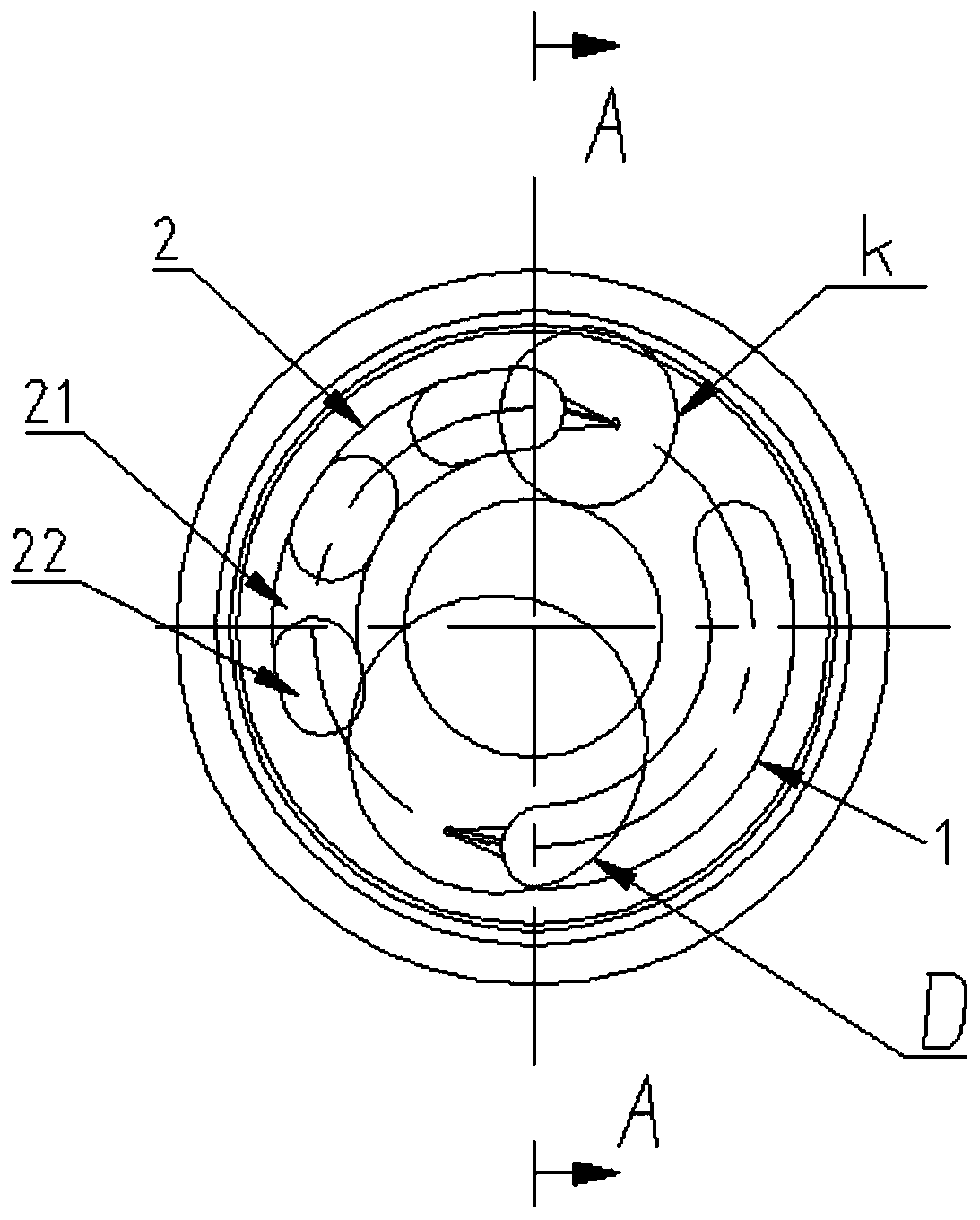

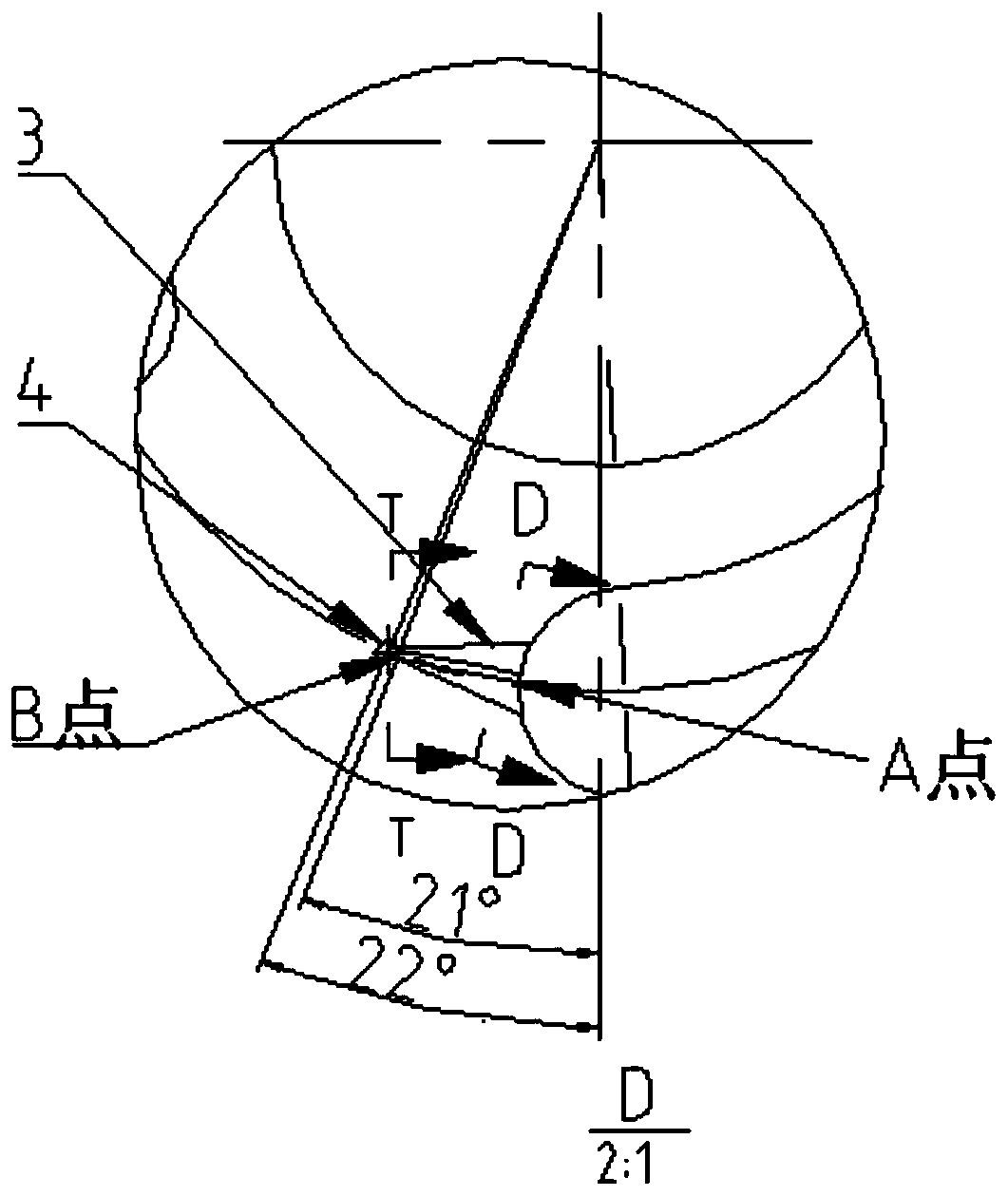

[0049] Such as figure 1 , 2 As shown in , 3 and 4, an axial piston pump distribution plate has a waist-shaped hole 1, which is located in the middle of the distribution plate and is a long hole formed by extending along the circumferential direction of the concentric circle of the distribution plate. A waist-shaped blind hole 2 is provided on the distribution plate at a position symmetrical to the circumference of the waist-shaped hole 1, and three through-holes 22 are provided in the waist-shaped blind hole 2, and an unloading valve is provided at the lower end of the waist-shaped hole 1. Groove 3 and damping hole 4, open the unloading groove 3 and damping hole 4 of same structure at the upper end of described waist-shaped blind hole 2;

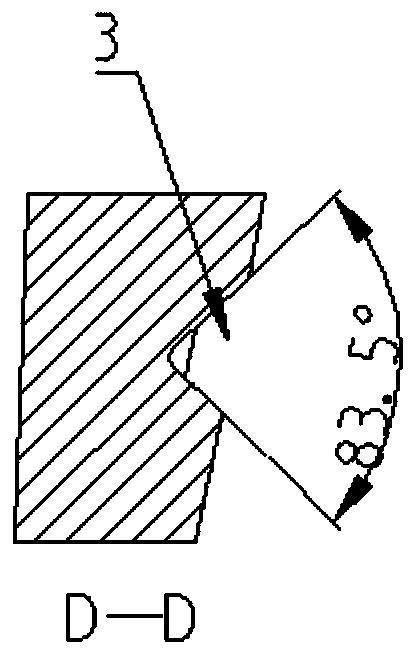

[0050] The unloading groove 3 is an open groove, and its c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com