Novel quickly-disassembled-and-assembled combined cofferdam with slope-retaining gallery for river channel

A technology of combining cofferdams and cofferdams, applied in artificial waterways, water conservancy projects, buildings, etc., can solve the problems of affecting the passage of cofferdams, unsatisfactory use, poor adaptability of walking wheels, etc., and achieve significant economic and social benefits. , The structure is novel and unique, the effect of solving the repair problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

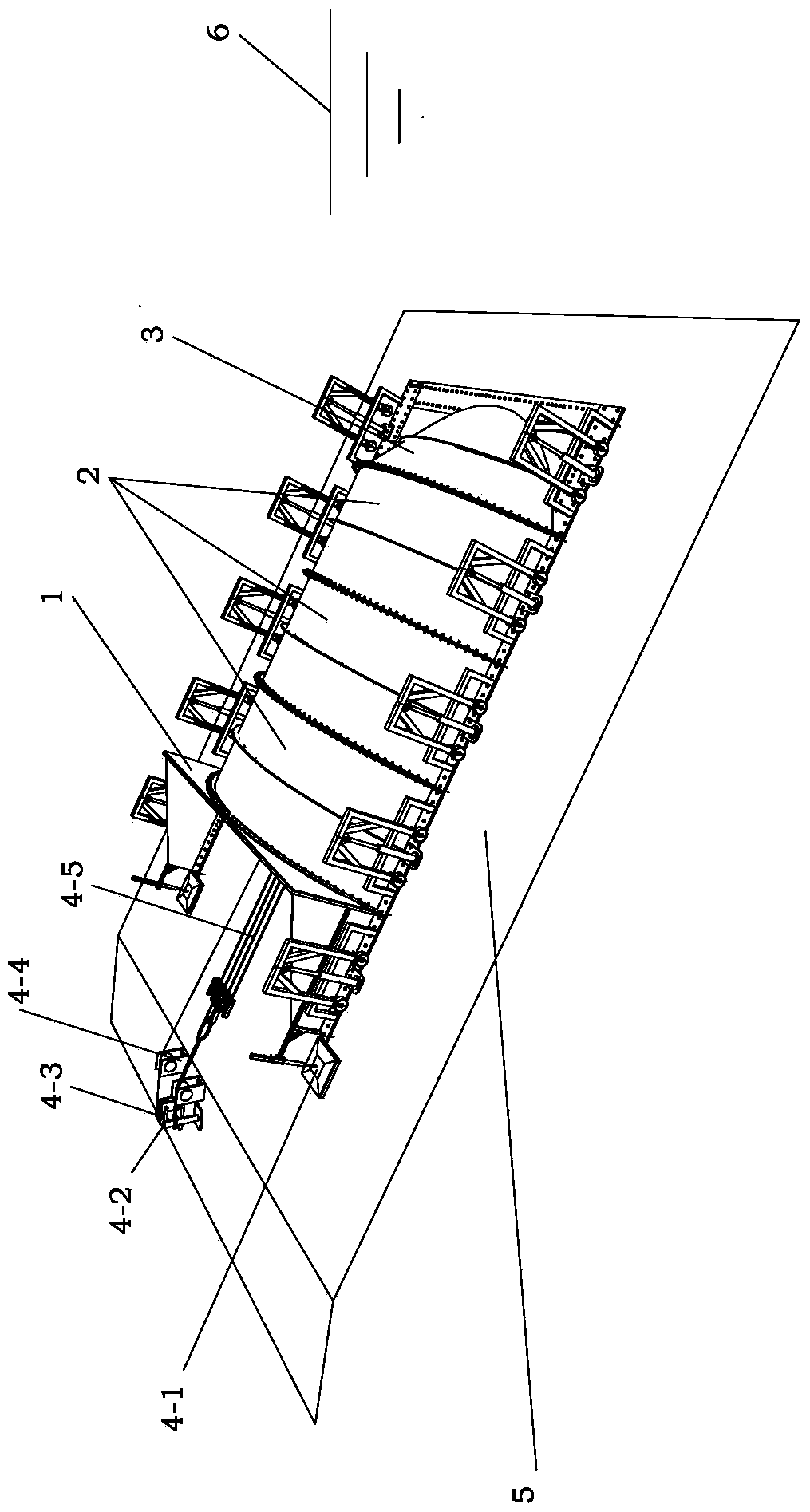

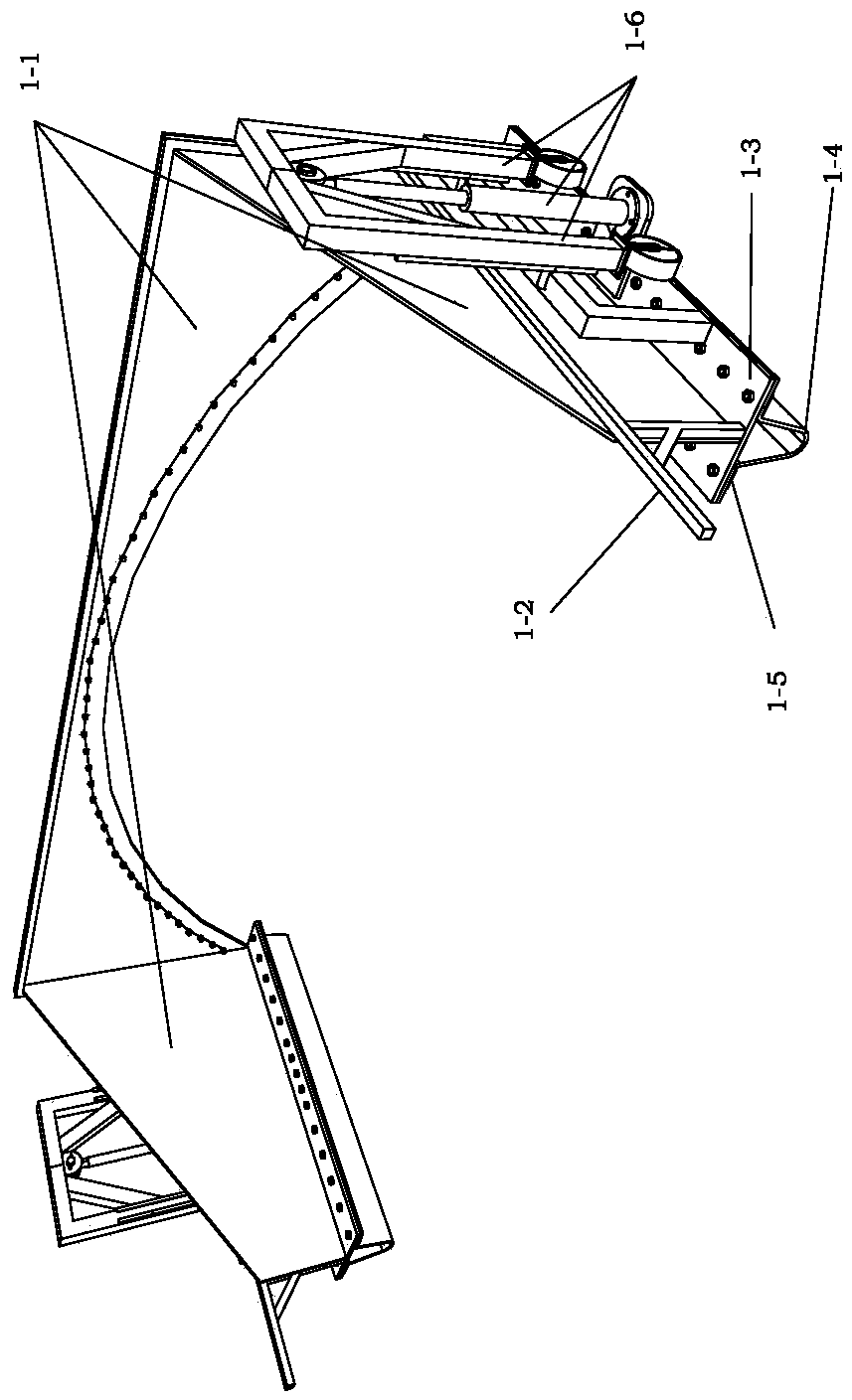

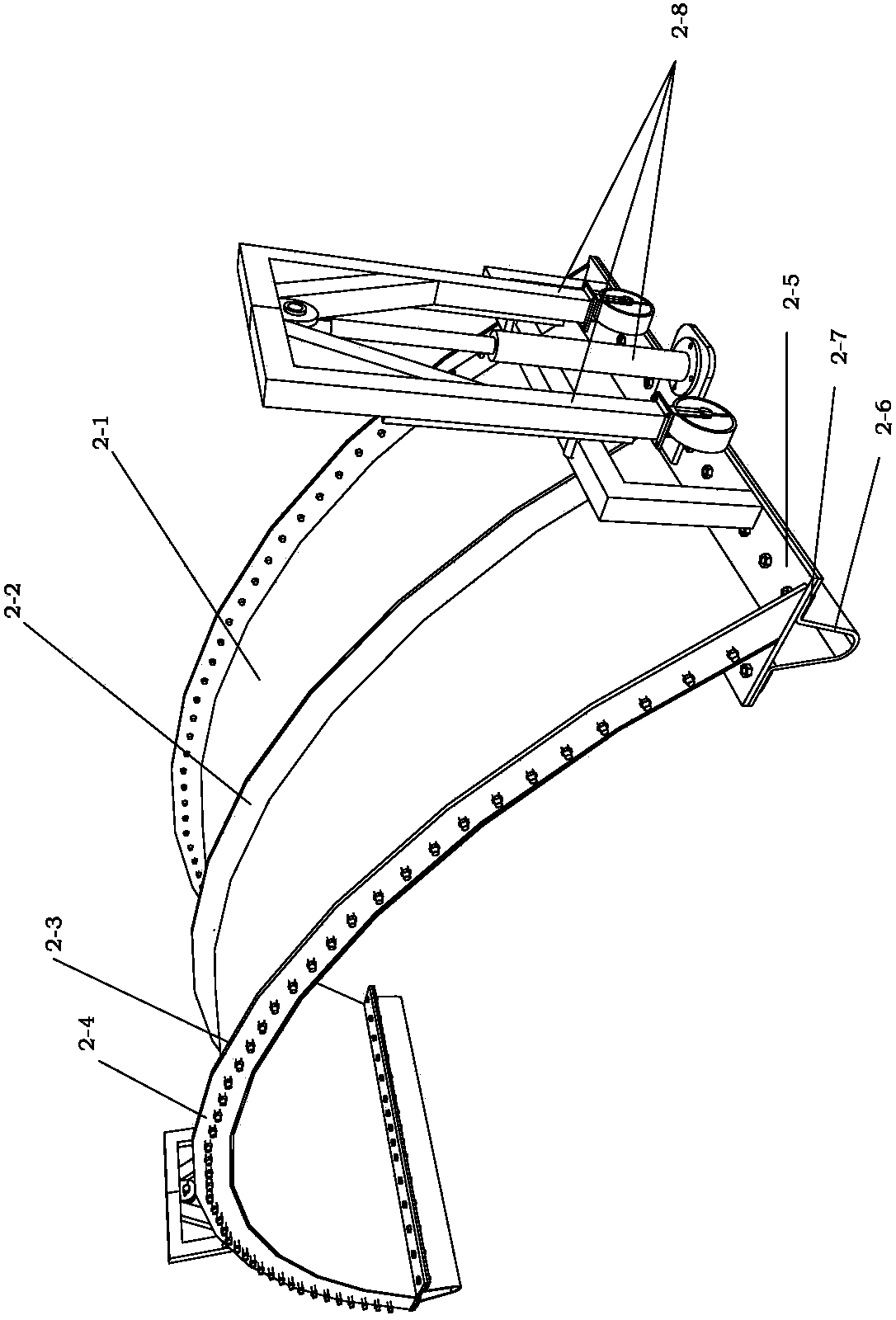

[0017] Depend on Figure 1-6 As shown, a novel river channel uphill corridor type quick disassembly combined cofferdam of the present invention comprises a cofferdam body, and the cofferdam body is composed of an inlet section cofferdam body 1, an intermediate section cofferdam body 2, a plug section cofferdam The cofferdam body 3 in the inlet section, the cofferdam body 2 in the middle section, and the cofferdam body 3 in the plug section are connected together through the rear connecting plate, flange and flange rubber gasket of the inlet section. , the front part of the cofferdam body 1 of the inlet section is equipped with a traction operation fixing device composed of ground anchor 4-2, winch 4-3 and pulley block 4-5, the front lower part is equipped with adsorption fixing device 4-1, ground anchor 4- 2 and the hoist 4-3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com