A beam end prestressed structure and its construction method

A prestressed structure and construction method technology, applied in bridges, bridge construction, bridge materials, etc., can solve problems such as difficulty in ensuring the quality of prestressed construction, difficulty in meeting production requirements, cutting off of main reinforcement under transverse force, etc., to reduce adverse effects, The effect of shortening the construction period and enhancing the overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

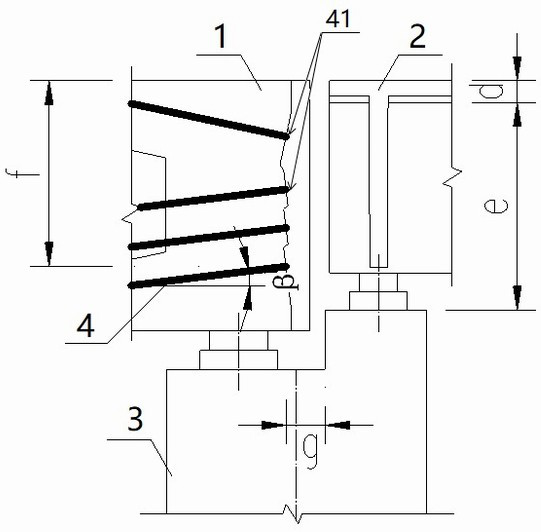

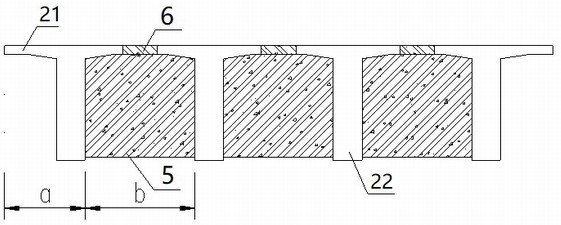

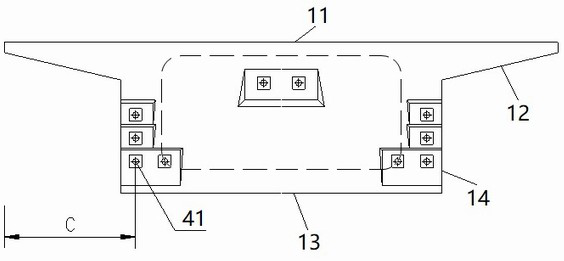

[0038] A beam end prestressed structure such as figure 1 As shown, it includes box girder 1, T girder structure, pier 3, prestressed steel beam 4, the adjacent span of the box girder 1 is the T girder structure, and the box girder 1 and the The junction of the T-beam structure is located on the pier 3. The T-beam structure includes an end beam 5 and a T-beam 2. The T-beam 2 has multiple pieces, and each piece of the T-beam 2 includes a T-beam flange plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com