Light low-loss fiber-reinforced aromatic nitrile-based resin matrix composite material and preparation method thereof

A fiber-reinforced, composite material technology used in sustainable manufacturing/processing, chemical industry, coatings, etc. to improve poor wettability, good film formation and toughness, and increase free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

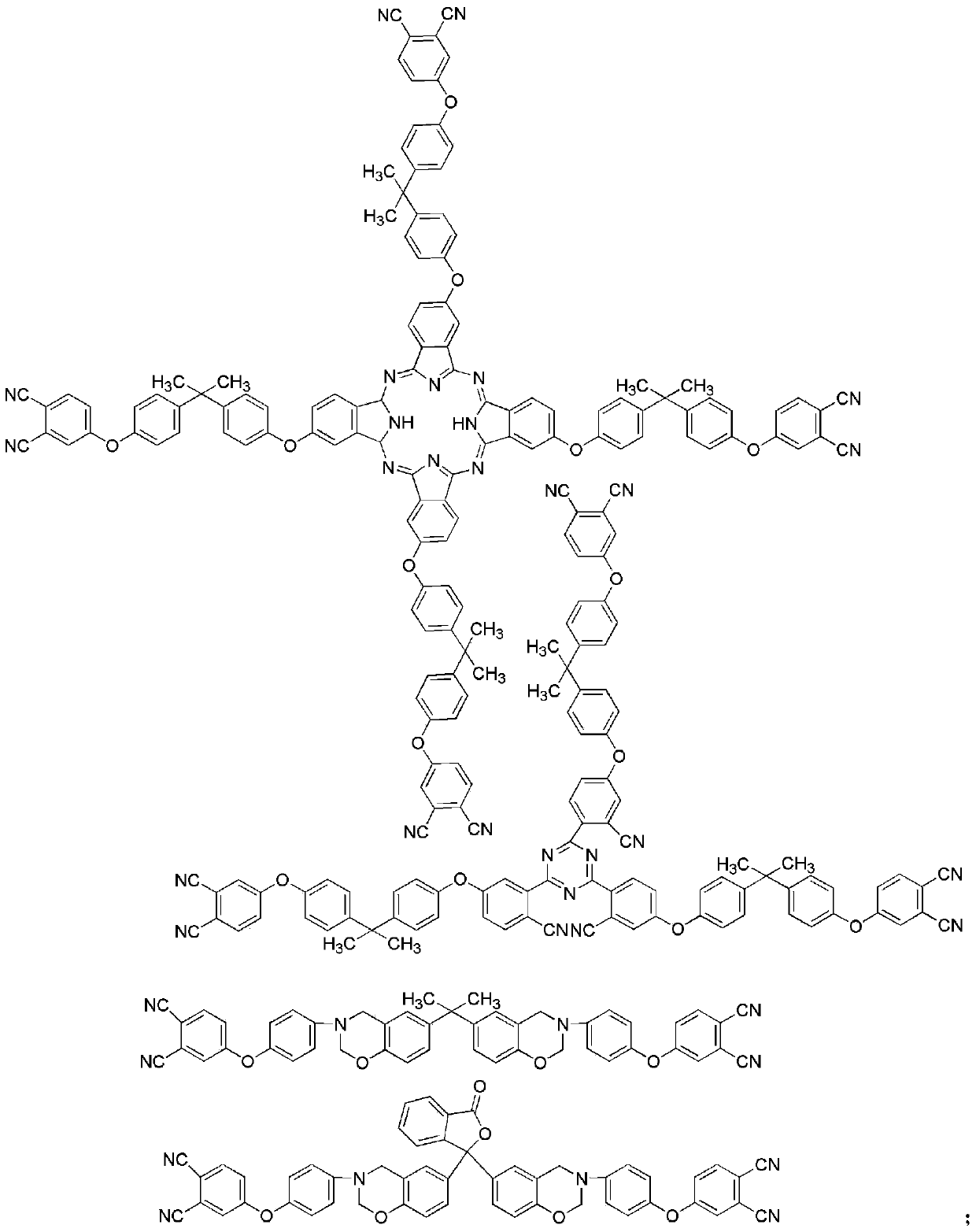

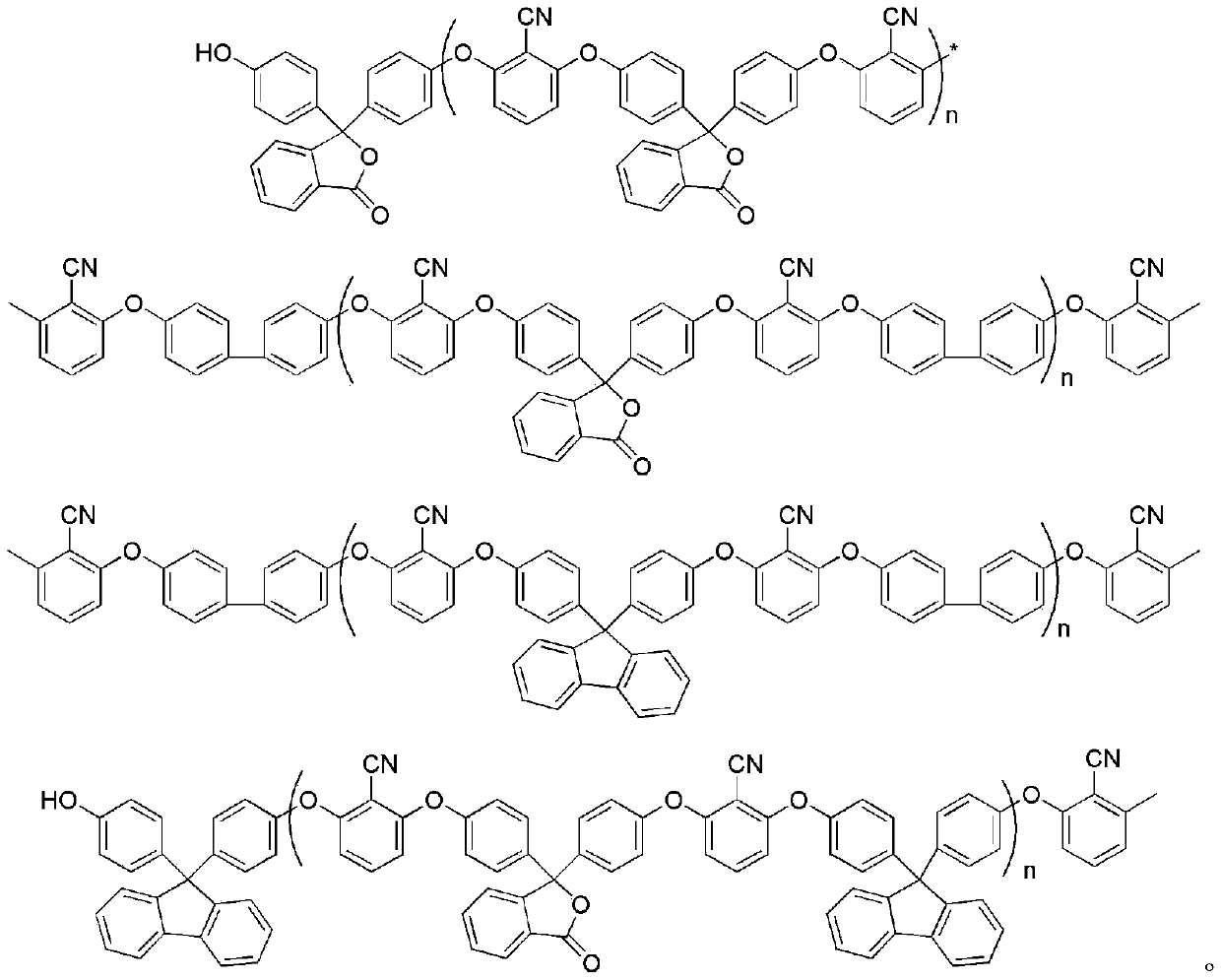

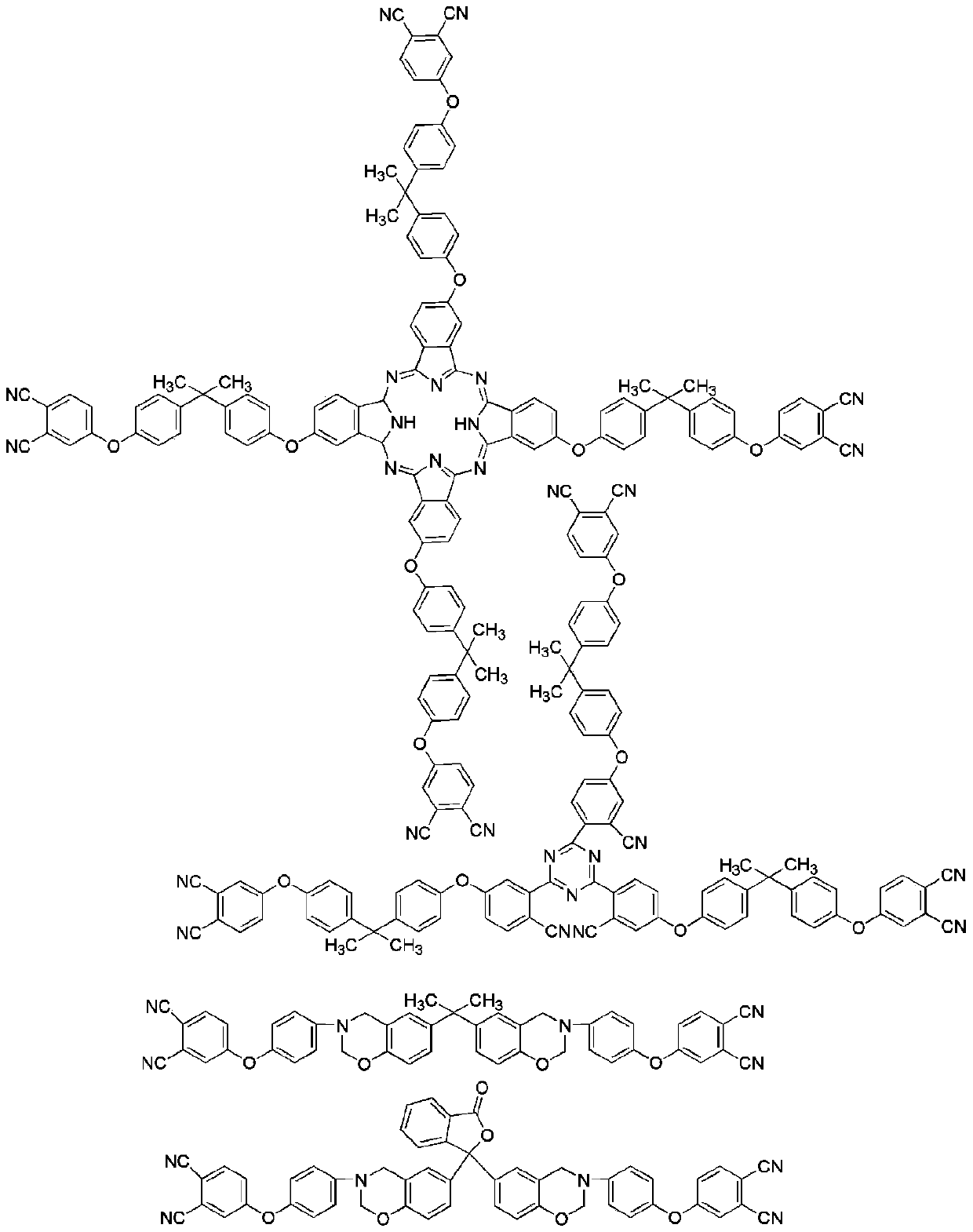

Method used

Image

Examples

Embodiment

[0052] The embodiment of the present invention discloses a method for preparing a lightweight low-loss fiber-reinforced aramid-based resin-based composite material, comprising the following steps:

[0053] (1) Aromatic nitrile resin A and aromatic nitrile resin B with a mass ratio of (0.6-0.9): (0.1-0.4) are sequentially added to N with a volume ratio of (0.6-0.8): (0.2-0.4), In the blended solvent of N-dimethylformamide and N-methylpyrrolidone, a homogeneous solution with a mass-to-liquid ratio of (0.5-0.6): (0.4-0.5) is obtained;

[0054] (2) Refluxing the homogeneous solution obtained in step (1) for 2-4 hours at 140-180° C. to obtain a uniform high-viscosity aromatic nitrile-based resin glue;

[0055] (3) heat-treating the quartz fiber in a drying oven at 200° C. for 30 minutes to remove the treatment agent on the surface of the fiber to obtain the treated quartz fiber;

[0056] (4) Cool the resin glue solution obtained in step (2) to about 60°C, introduce it into the dip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com