Multi-stage energy recovery device and process for coal water slurry gasified black water

An energy recovery device and coal-water slurry technology, which is applied in gasification process, chemical industry, water/sewage treatment, etc., can solve the problems of limited pressure potential energy recovery effect, black water pressure reduction, flow rate increase, etc., to solve erosion corrosion Serious, simple structure, effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

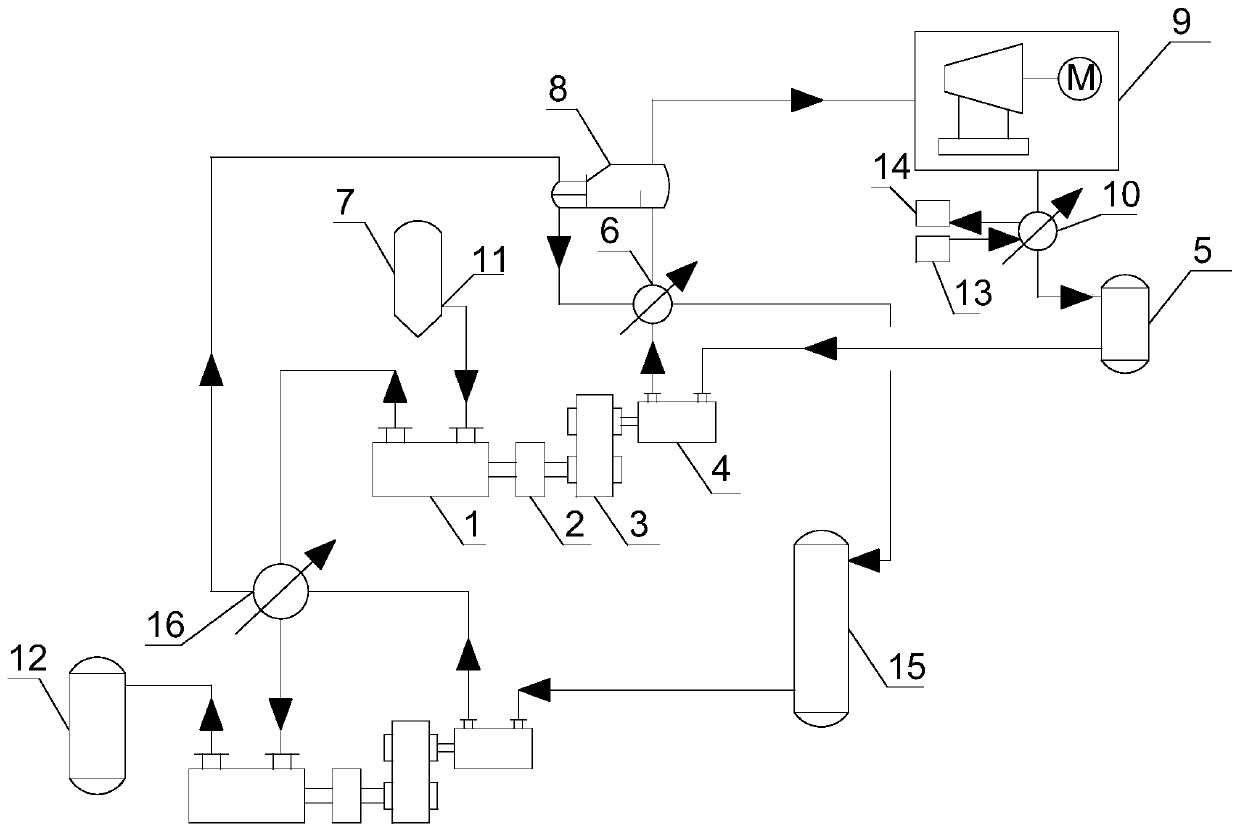

Embodiment 1

[0043] A multi-stage energy recovery device for coal-water slurry gasification black water, comprising a gasifier 7 with a black water outlet 11 and an evaporating hot water tower 12, the black water outlet 11 and the black water outlet 11 of the gasifier 7 A multi-stage energy recovery unit is arranged between the evaporative hot water towers 12; the multi-stage energy recovery unit includes at least two turbine units for recovering black water potential energy, and is arranged between adjacent turbine units for recovery of black water Heat recovery unit for thermal energy. The turbo unit includes a turbo pump 1 , and the mechanical end of the turbo pump 1 is connected with a working medium pump 4 through a motor 2 and a transmission 3 in sequence. The multi-stage energy recovery unit includes the turbine pump 1 of the upper turbine unit connected to the black water outlet 11 in the gasifier 7, the heat recovery unit, and the turbine unit of the lower turbine unit connected t...

Embodiment 2

[0054] A multi-stage energy recovery device for coal-water slurry gasification black water, comprising a gasifier 7 with a black water outlet 11 and an evaporating hot water tower 12, the black water outlet 11 and the black water outlet 11 of the gasifier 7 A multi-stage energy recovery unit is arranged between the evaporative hot water towers 12; the multi-stage energy recovery unit includes at least two turbine units for recovering black water potential energy, and is arranged between adjacent turbine units for recovery of black water Heat recovery unit for thermal energy. The turbo unit includes a turbo pump 1 , and the mechanical end of the turbo pump 1 is connected with a working medium pump 4 through a motor 2 and a transmission 3 in sequence. The multi-stage energy recovery unit includes the turbine pump 1 of the upper turbine unit connected to the black water outlet 11 in the gasifier 7, the heat recovery unit, and the turbine unit of the lower turbine unit connected t...

Embodiment 3

[0065] A multi-stage energy recovery device for coal-water slurry gasification black water, comprising a gasifier 7 with a black water outlet 11 and an evaporating hot water tower 12, the black water outlet 11 and the black water outlet 11 of the gasifier 7 A multi-stage energy recovery unit is arranged between the evaporative hot water towers 12; the multi-stage energy recovery unit includes at least two turbine units for recovering black water potential energy, and is arranged between adjacent turbine units for recovery of black water Heat recovery unit for thermal energy. The turbo unit includes a turbo pump 1 , and the mechanical end of the turbo pump 1 is connected with a working medium pump 4 through a motor 2 and a transmission 3 in sequence. The multi-stage energy recovery unit includes the turbine pump 1 of the upper turbine unit connected to the black water outlet 11 in the gasifier 7, the heat recovery unit, and the turbine unit of the lower turbine unit connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com