Production process and application of magnesium hydroxide suspension with high solid content

A magnesium hydroxide, high solid content technology, applied in magnesium hydroxide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complicated preparation process, long reaction time, low solid content of slurry, etc., and achieve desulfurization Good effect, short preparation time and good suspension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention discloses a production process of magnesium hydroxide suspension with high solid content, comprising a detection step, a crushing step, and a slurry preparation step.

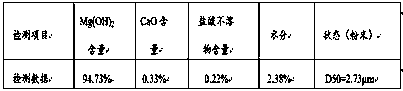

[0036] Described detection step, get the magnesium hydroxide by-product of lithium carbonate industry as raw material A, described raw material A is detected, if the detection result of described raw material A satisfies following index, then enter next step:

[0037]

[0038] The pulverization step is dry pulverization, including coarse pulverization and superfine pulverization;

[0039] For the coarse crushing, the raw material A is crushed by a jaw crusher, and then pulverized by a hammer mill to 20 mesh to 40 mesh to obtain raw material A0.

[0040] For the ultrafine pulverization, the raw material A0 is pulverized through a horizontal mechanical ultrafine pulverizer, and the parameters of the superfine pulverizer are controlled as follows: the feed rate is 8Hz, the speed of the pulv...

Embodiment 2

[0045]The invention discloses a production process of magnesium hydroxide suspension with high solid content, comprising a detection step, a crushing step, and a slurry preparation step.

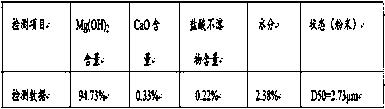

[0046] Described detection step, get the magnesium hydroxide by-product of lithium carbonate industry as raw material A, described raw material A is detected, if the detection result of described raw material A satisfies following index, then enter next step:

[0047]

[0048] The pulverization step is dry pulverization, including coarse pulverization and superfine pulverization;

[0049] For the coarse crushing, the raw material A is crushed by a jaw crusher, and then pulverized by a hammer mill to 20 mesh to 40 mesh to obtain raw material A0.

[0050] For the ultrafine pulverization, the raw material A0 is pulverized through a horizontal mechanical ultrafine pulverizer, and the parameters of the superfine pulverizer are controlled as follows: the feed rate is 8Hz, the speed of the pulve...

Embodiment 3

[0055] The invention discloses a production process of magnesium hydroxide suspension with high solid content, comprising a detection step, a crushing step, and a slurry preparation step.

[0056] Described detection step, get the magnesium hydroxide by-product of lithium carbonate industry as raw material A, described raw material A is detected, if the detection result of described raw material A satisfies following index, then enter next step:

[0057]

[0058] The pulverization step is dry pulverization, including coarse pulverization, ultrafine pulverization, and jet pulverization;

[0059] For the coarse crushing, the raw material A is crushed by a jaw crusher, and then pulverized by a hammer mill to 20 mesh to 40 mesh to obtain raw material A0.

[0060] For the ultrafine pulverization, the raw material A0 is pulverized through a horizontal mechanical ultrafine pulverizer, and the parameters of the superfine pulverizer are controlled as follows: the feed rate is 8Hz, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com