Intermittent rotation and middle punching device for glass vase

A vase and glass technology, applied in the field of intermittent rotation and middle hole opening device, can solve the problem of low hole opening efficiency of glass vases, and achieve the effect of increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

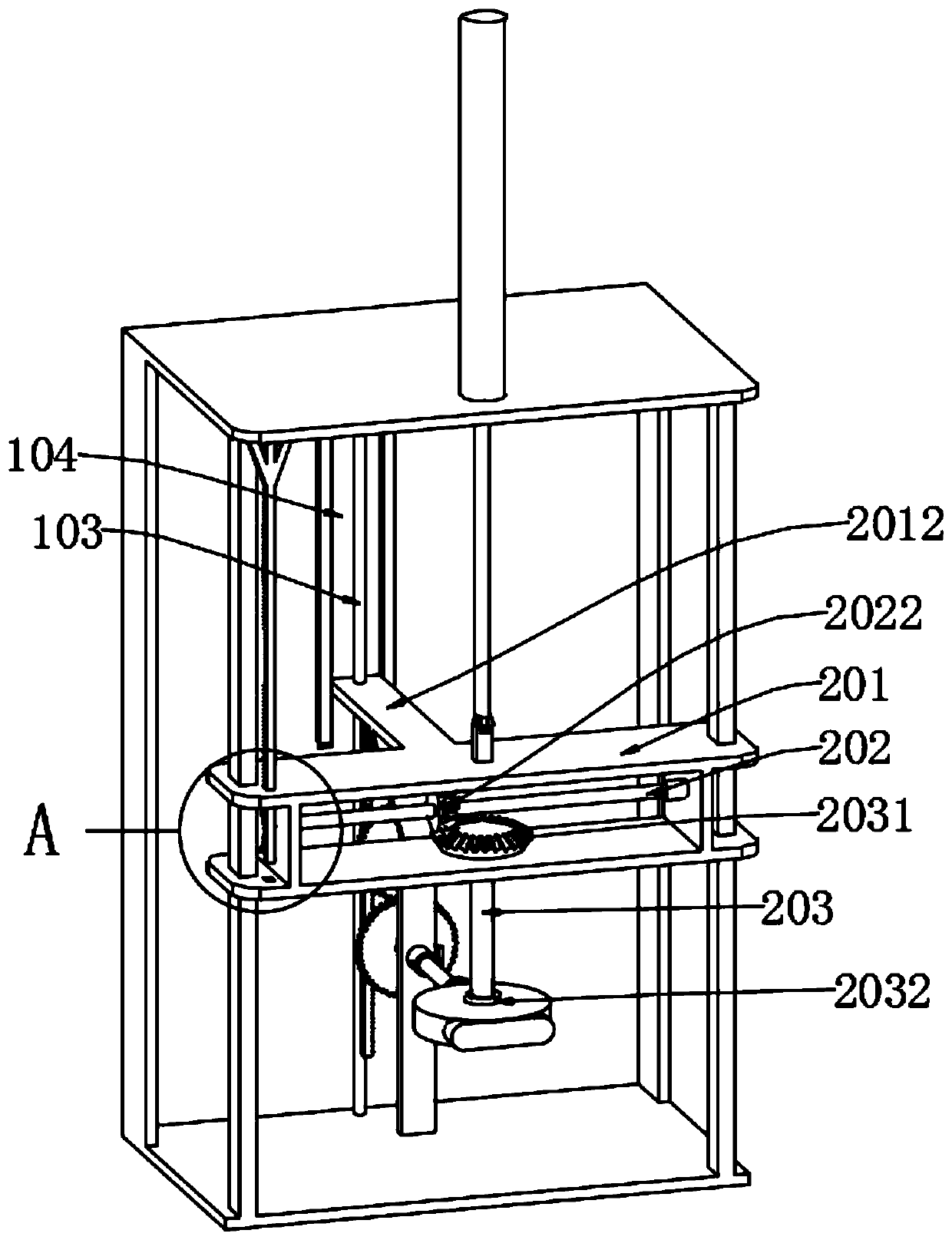

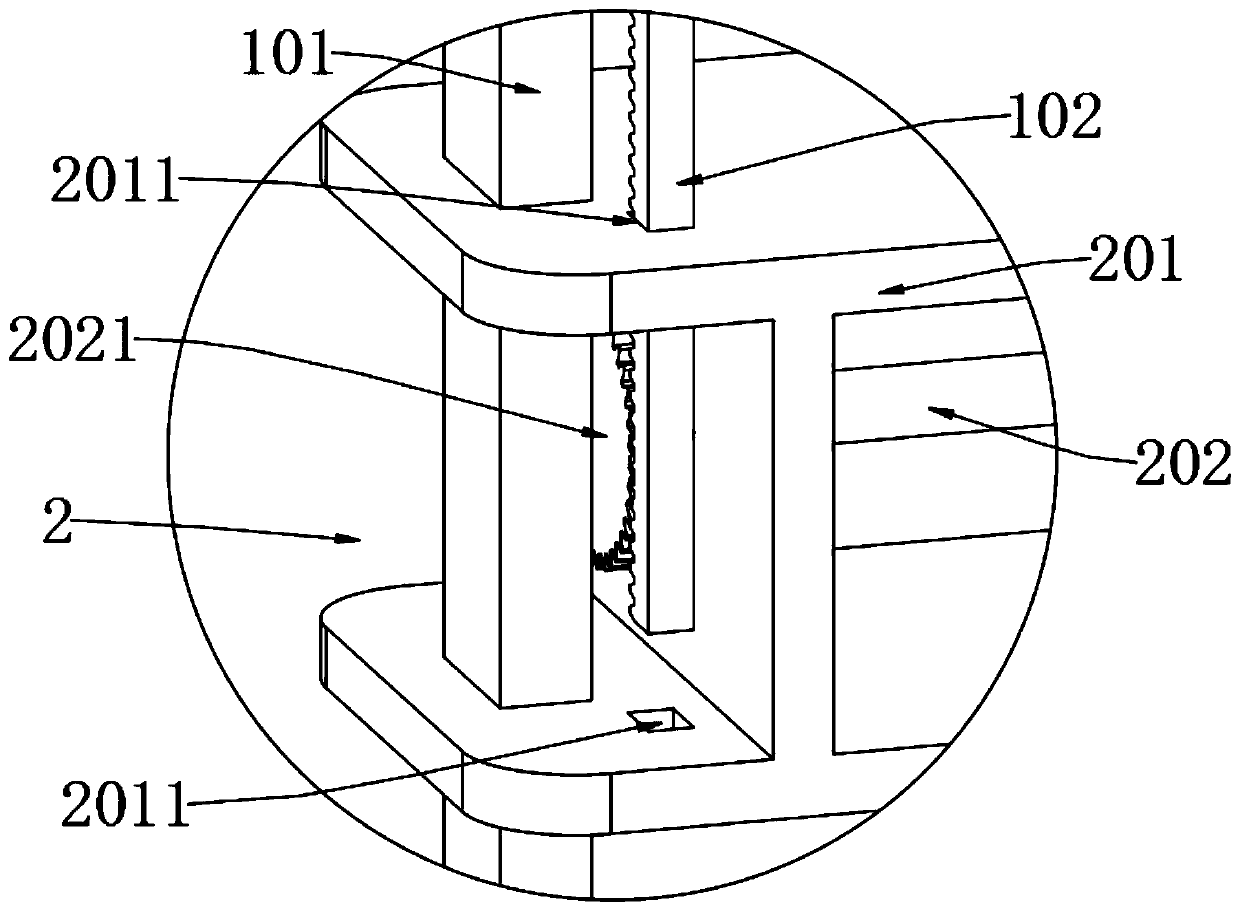

[0031] as attached Figure 1-3 to attach Figure 7 Shown:

[0032] The present invention provides a device for intermittent rotation and middle opening of glass vases, which includes a rotary opening mechanism 2; The top of mechanism 2 is fixedly connected with the telescoping end of electric cylinder 4 by bolts, and the interior rear side end of frame body 1 is also equipped with vase intermittent rotation mechanism 3, and vase intermittent rotation mechanism 3 is connected with rotary opening mechanism 2 transmission.

[0033] Wherein, the rotary drilling mechanism 2 includes an adjustment frame 201, a horizontal shaft 202, a side gear 2021, a horizontal bevel gear 2022, a hole shaft 203, a vertical bevel gear 2031 and a hole opening head 2032, and the adjustment frame 201 is slidably installed on the frame On the front guide column 101 at the front end of the inner side of the body 1, and the middle of the adjustment frame 201 is inlaid with a horizontal shaft 202, and th...

Embodiment 2

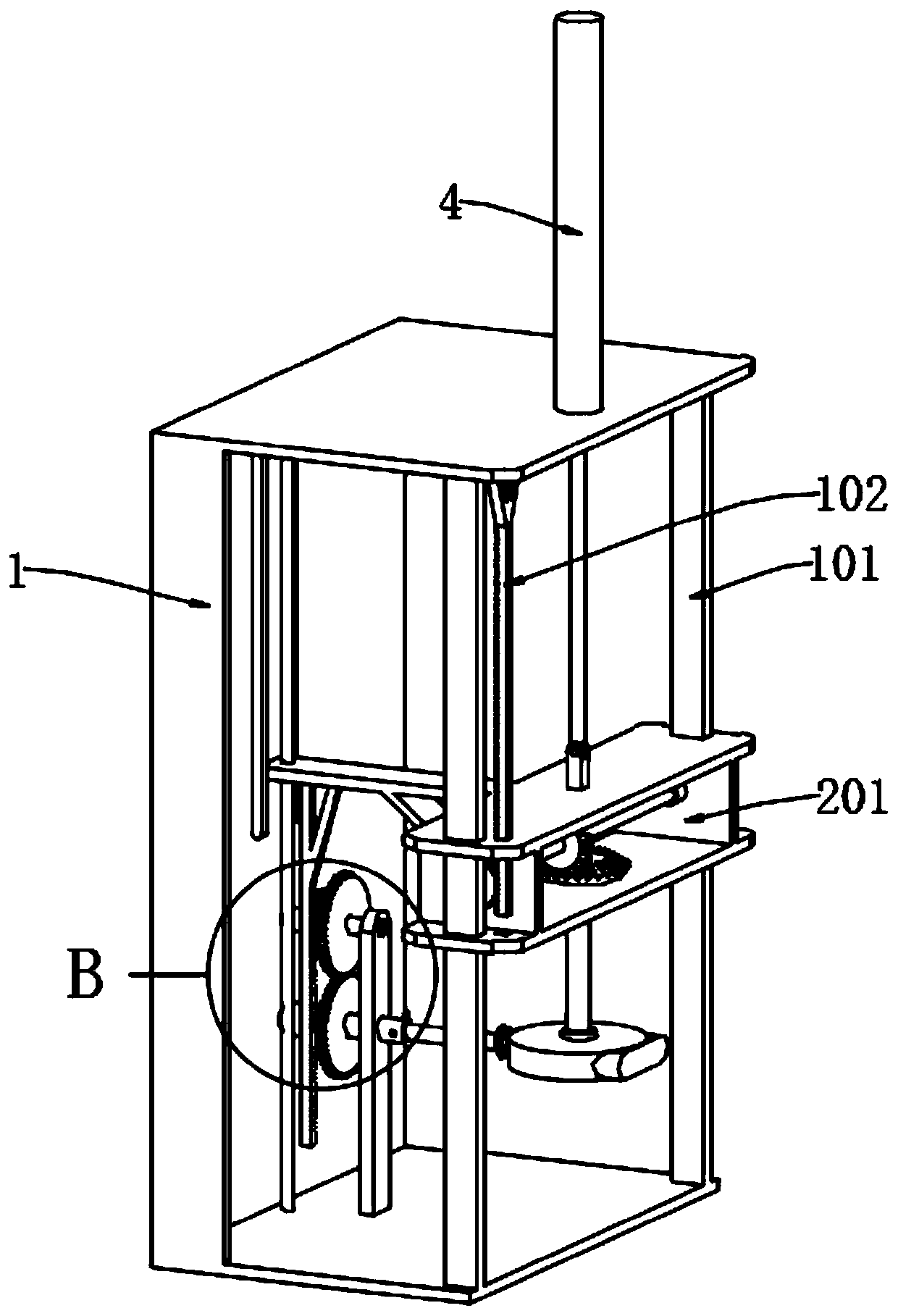

[0036] On the basis of embodiment 1, as attached Figure 4-6 , attached Figure 8 And attached Figure 9 Shown:

[0037] The present invention provides an intermittent rotation and middle opening device for glass vases. The vase intermittent rotation mechanism 3 includes an intermittent rotation shaft 301, an intermittent rotation gear 3013, a linkage shaft 302, an incomplete gear 3021, a ratchet device 3022 and a support frame 303. The intermittent rotation gear 3013 is clamped on the intermittent rotating shaft 301 and can mesh with the locking teeth on the incomplete gear 3021, and the incomplete gear 3021 is clamped on the linkage shaft 302, and the rear end of the linkage shaft 302 is also clamped with a ratchet device 3022 , and the front ends of the linkage shaft 302 and the intermittent rotating shaft 301 are respectively supported and fixed by the support frame 303 .

[0038] Wherein, the front end side of the intermittent rotating shaft 301 is also provided with a s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap