Bogie frame position internal self-turning-over device, system and method

A self-turning, bogie technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of tight tire positions and narrow working space for tire positions, saving space, improving safety, and reducing personnel. Effects of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

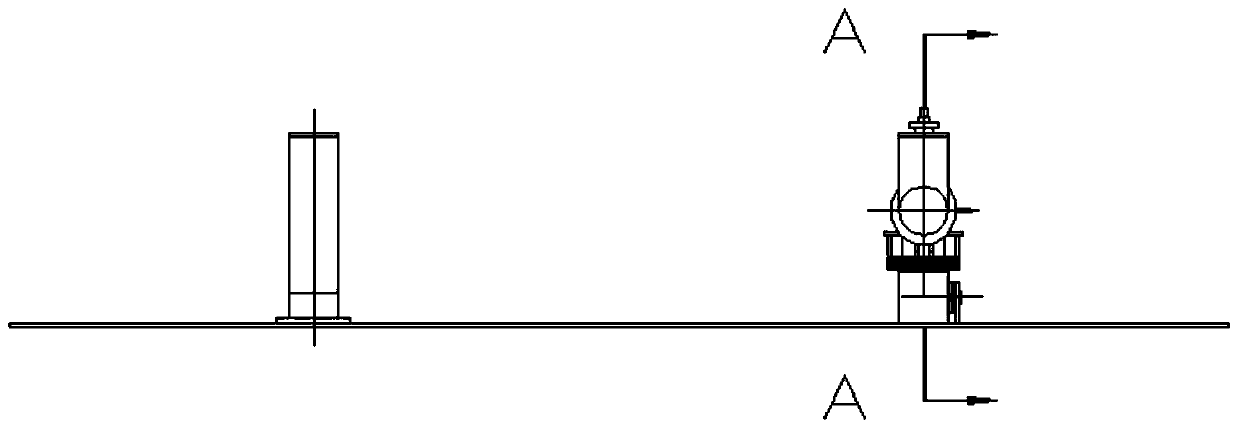

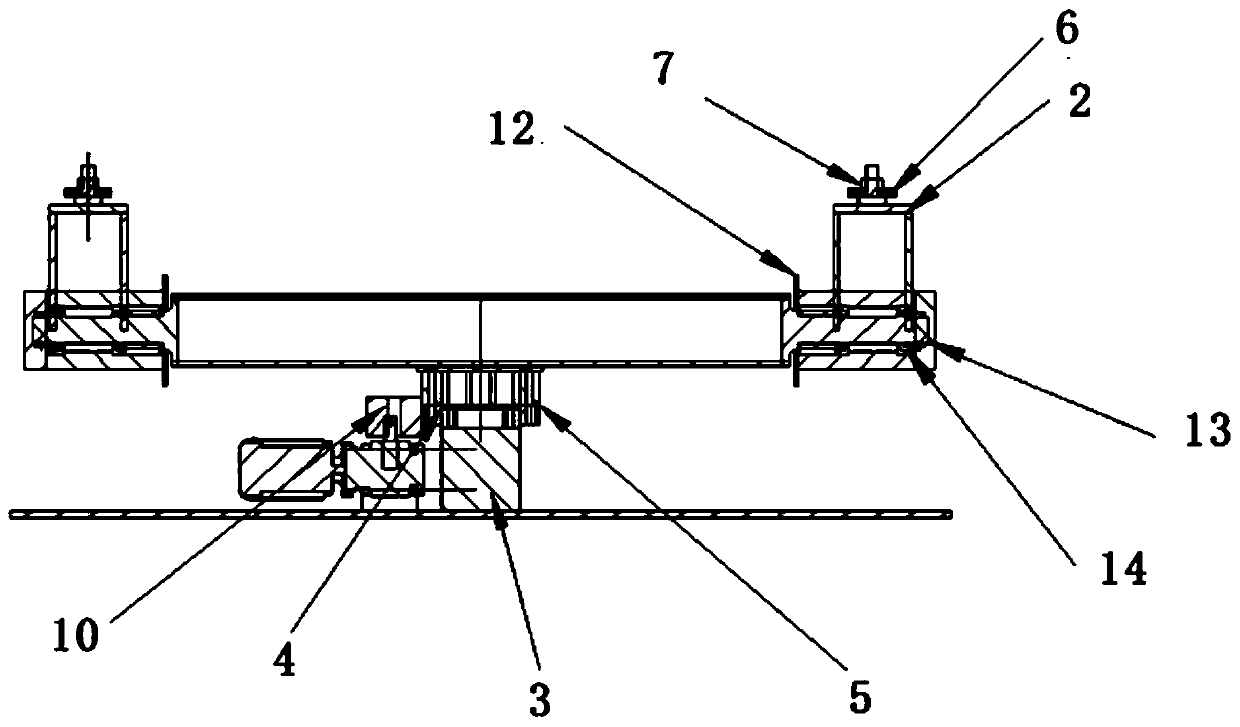

[0042] In a typical implementation of the present invention, the present invention is introduced by taking the overturning bogie frame as an example, as Figure 13 Shown is a schematic diagram of the device supporting the bogie frame of the present invention. The self-turning device in the tire position of the bogie frame proposed by the present invention is as follows: figure 1 As shown, it includes a driving member, a rotating beam, a first support, a second supporting member and a fastener; the driving member is used to drive the rotating beam to rotate in a horizontal plane; the second supporting member , which are arranged at both ends of the turning beam to support two corners of the bogie frame; and the second supporting member can rotate along the axis of the turning beam; The top of the second support is used to fasten the bogie to the turning beam; the first support supports the other two corners of the bogie frame.

[0043] Specifically, such as figure 1As shown,...

Embodiment 2

[0068] This embodiment also provides a bogie manufacturing system, including the self-turning device in the bogie frame tire position described in Embodiment 1, which is mainly used for bogie manufacturing.

Embodiment 3

[0070] The embodiment also provides a bogie overhaul system, which includes the above-mentioned self-turning device in the bogie frame tire position, and is mainly used for bogie overhaul.

[0071] It should be noted that the self-turning device in the tire position of the frame disclosed in this embodiment is not only applicable to the bogie frame disclosed in this embodiment, but also applicable to the turning of other frames.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com