A hot stamping method based on sheet metal

A metal plate and plate technology, applied in the field of plate stamping, can solve the problems of scalding, inconvenient plate placement, poor coating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

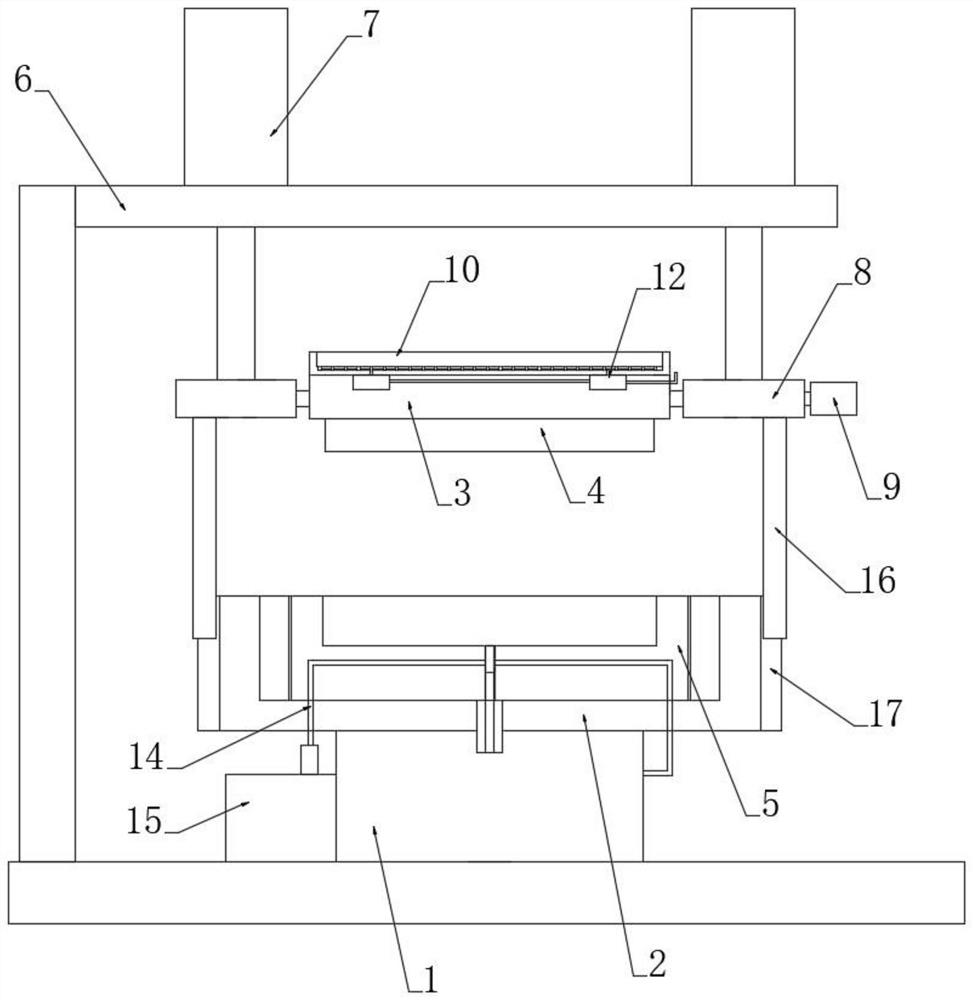

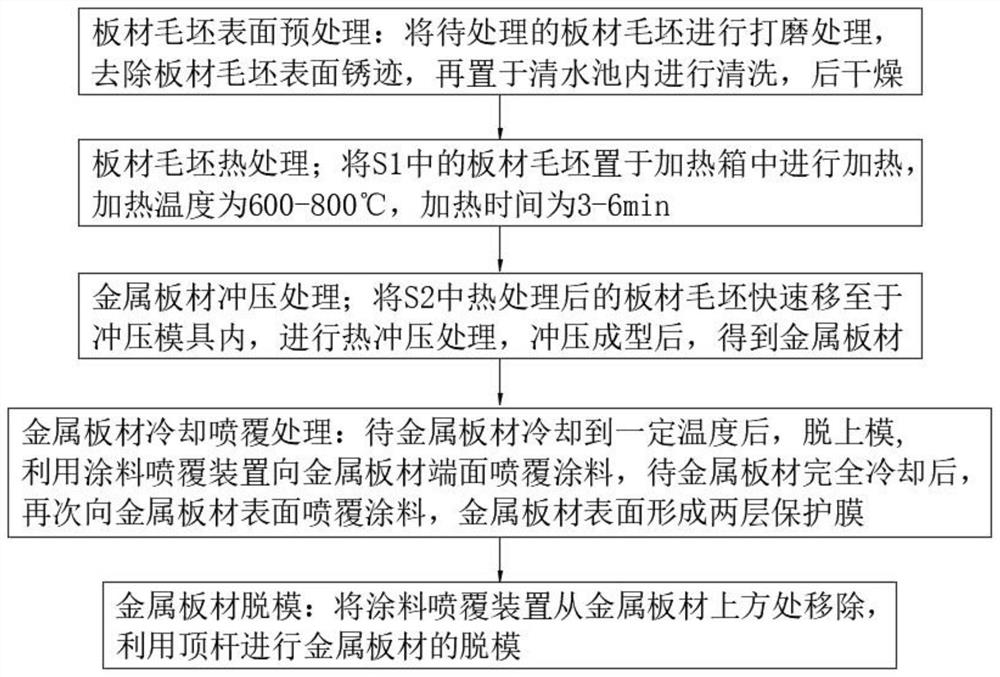

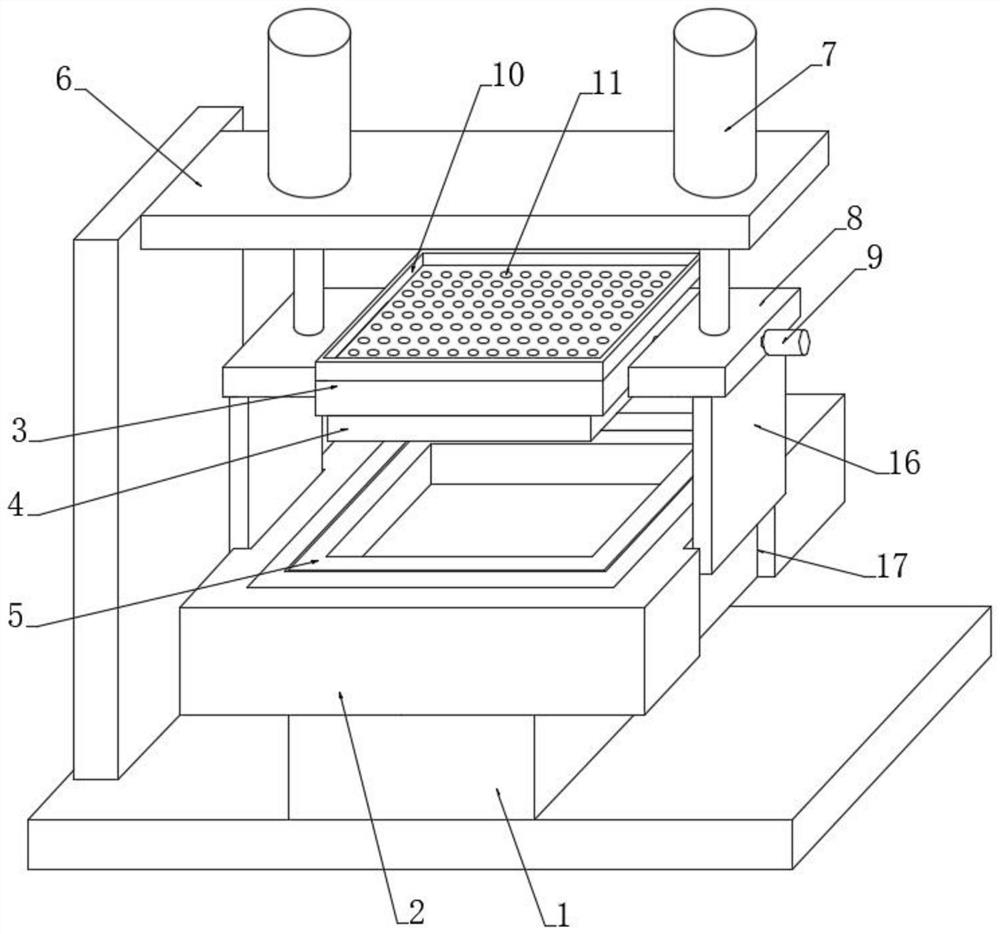

[0042] see figure 1 , a heating stamping method based on sheet metal, the specific heating stamping method is as follows:

[0043] S1. Pretreatment of the surface of the rough plate: grind the rough plate to be processed, remove the rust on the surface of the rough plate, and then put it in a clean water pool for cleaning and drying;

[0044] S2, heat treatment of the plate blank; place the plate blank in S1 in a heating box for heating, the heating temperature is 600-800°C, and the heating time is 3-6min;

[0045] S3. Metal plate stamping treatment: quickly move the plate blank after the heat treatment in S2 into the stamping die, perform hot stamping treatment, and obtain the metal plate after stamping and forming.

[0046] S4. Metal plate cooling and spraying treatment: After the metal plate in S3 is cooled to a certain temperature, take off the upper mold, and use the paint spraying device to spray paint on the end face of the metal plate. Spray paint, and form two layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com