An internal cleaning device suitable for different sizes of test tubes

A technology for cleaning devices and test tubes, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unsatisfactory cleaning effect, small application range, inconvenient cleaning, etc., and achieve good cleaning effect and wide application range Wide, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

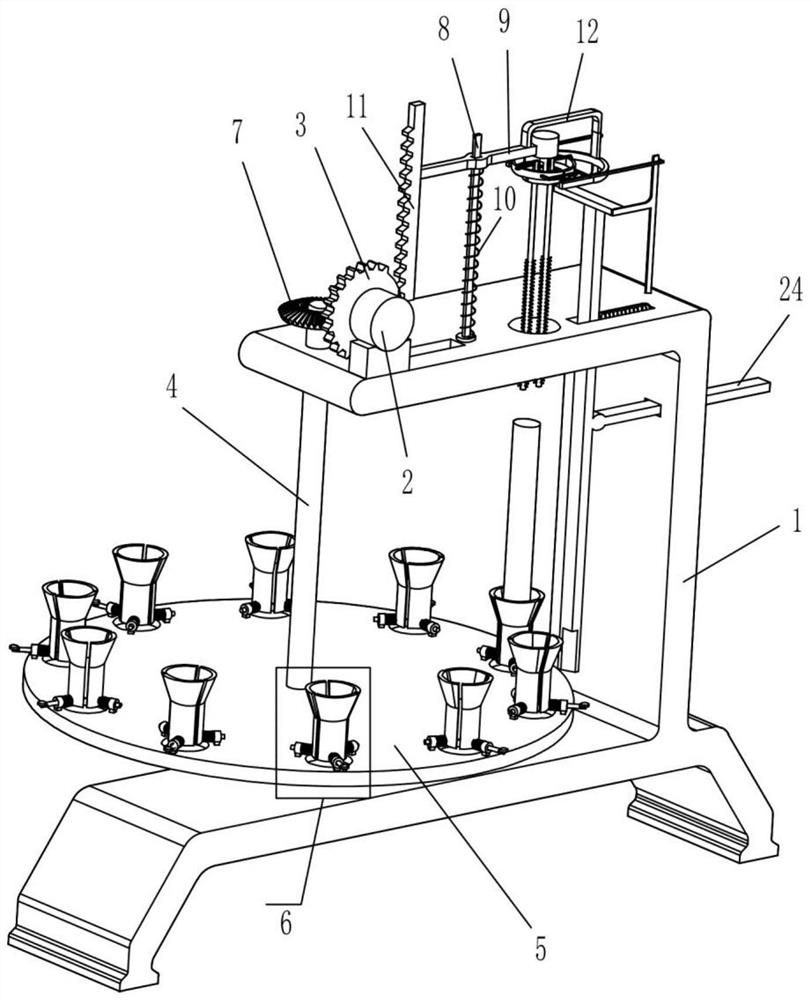

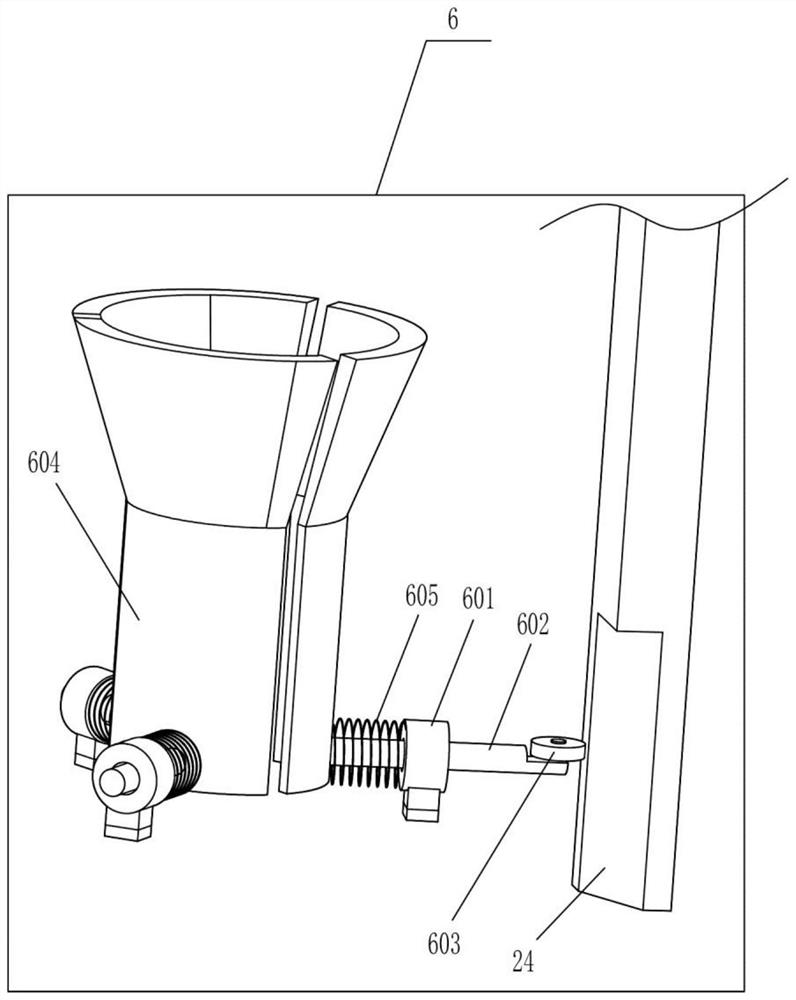

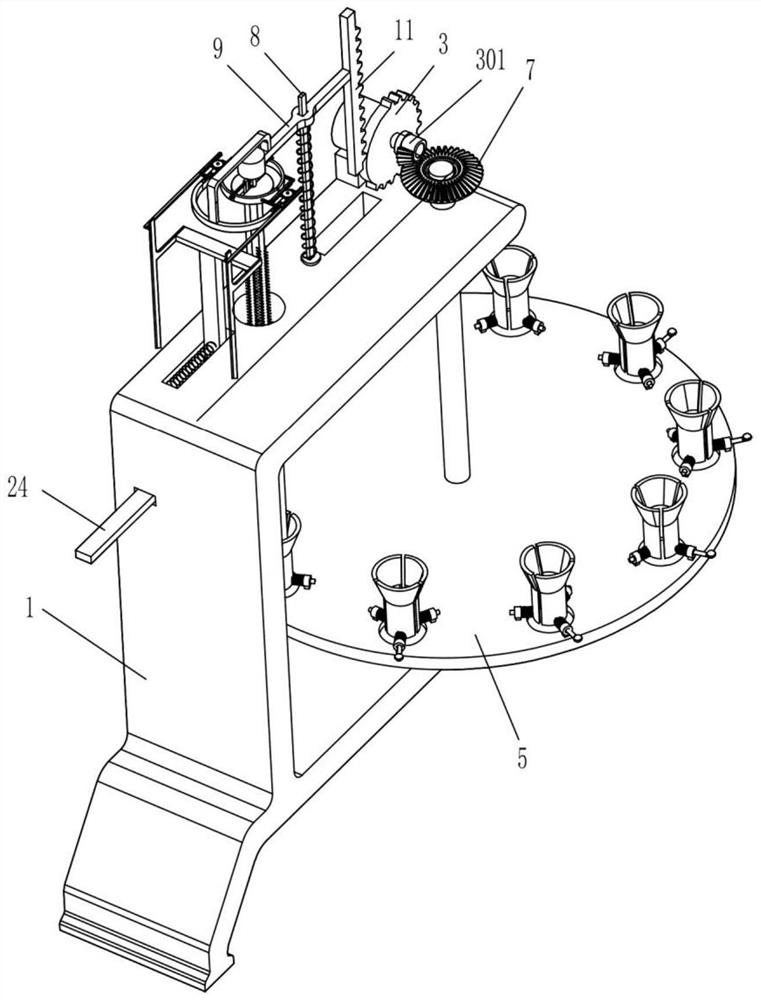

[0020] Embodiment: a kind of test tube internal cleaning device suitable for different sizes, such as Figure 1-6 As shown, it includes a support 1, a transmission motor 2, a sector gear 3, a tooth-missing bevel gear 301, a rotating shaft 4, a turntable 5, a clamping part 6, a transmission bevel gear 7, a sliding rod 8, a movable rod 9, and a return spring 10. Transmission rack 11 and support plate 12, the transmission motor 2 is fixedly installed on the left end of the upper side of the support 1, the sector gear 3 is installed on the output shaft of the transmission motor 2, the bevel gear 301 with missing teeth Set coaxially with the sector gear 3, the rotating shaft 4 is installed on the support 1 through a bearing and passes through the support 1, the upper end of the rotating shaft 4 is equipped with a transmission bevel gear 7 meshing with the tooth-less bevel gear 301, The lower end of the rotating shaft 4 is equipped with a turntable 5 and is located above the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com