JWXC-1700 type relay small-capacity load reliability test system

A technology of JWXC-1700, 1. JWXC-1700, applied in the field of relay reliability testing, can solve problems such as poor electrical conductivity, no connection, surface oxidation, etc., and achieve the effects of reducing poor contact, improving product quality, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

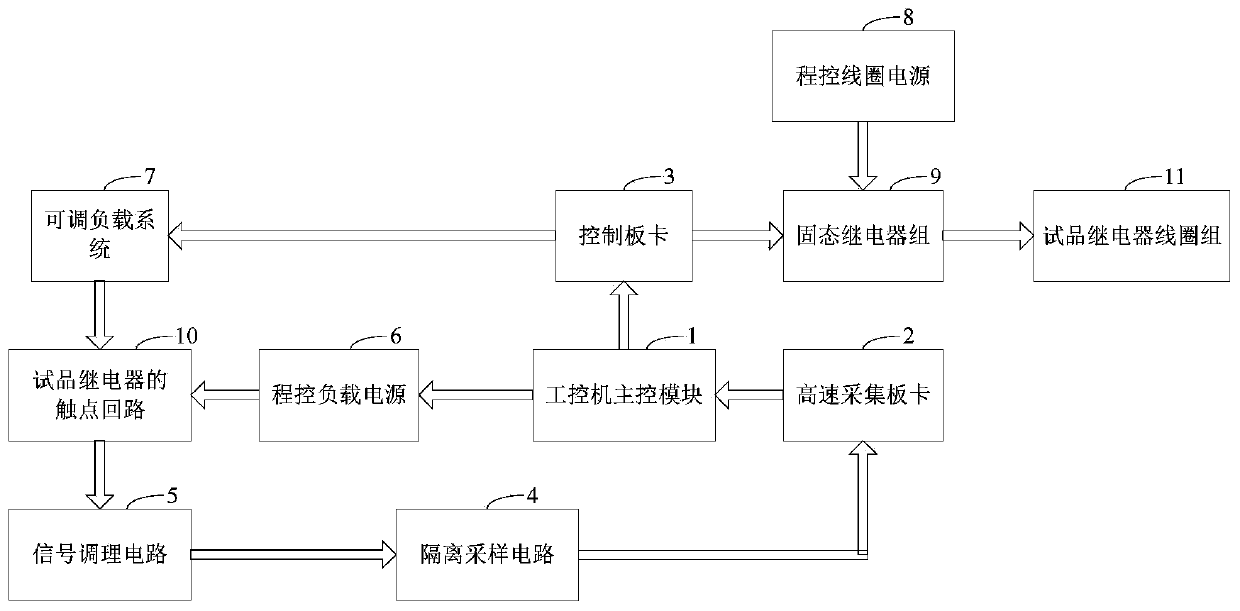

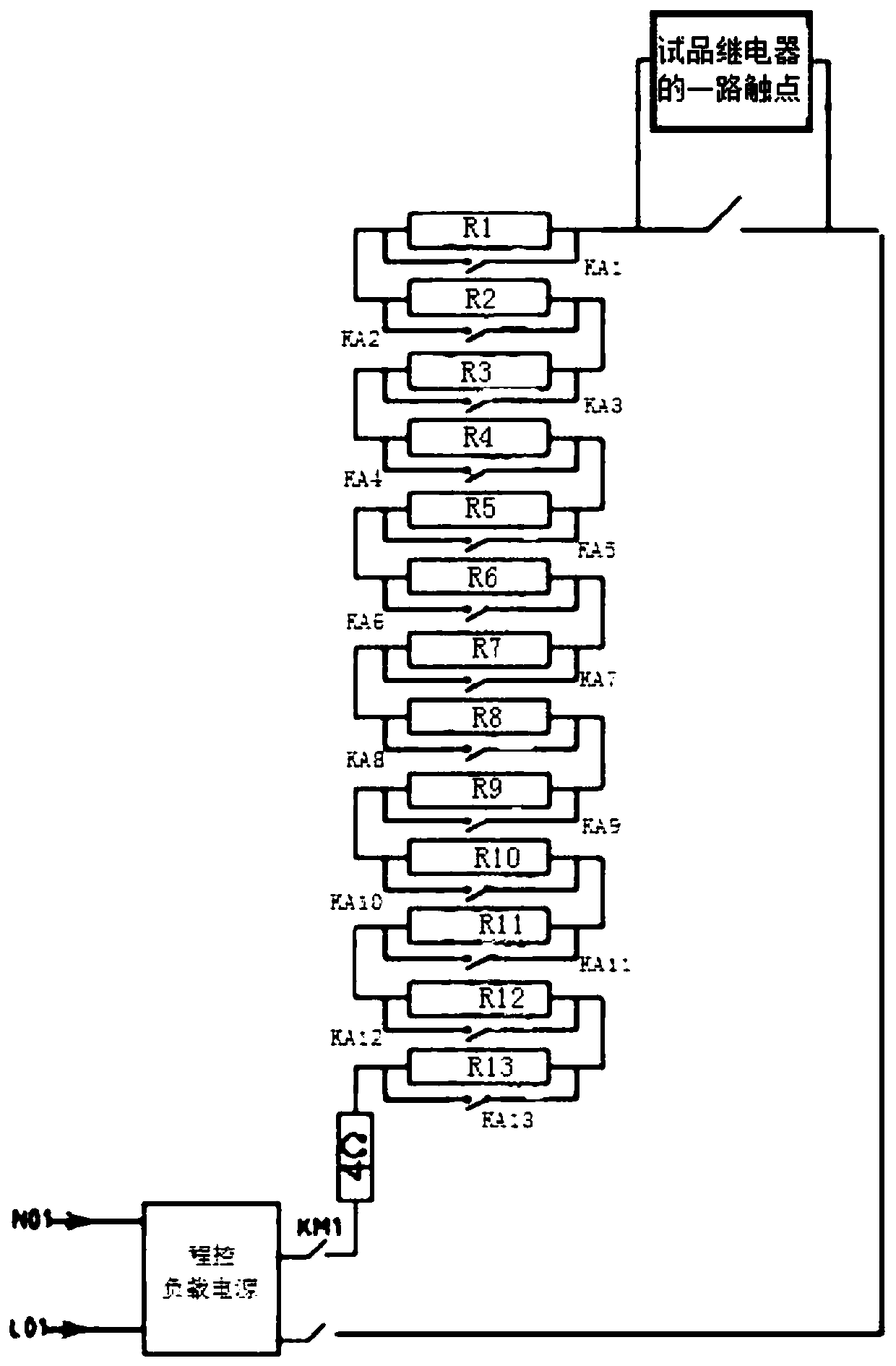

[0020] like figure 1 As shown, a JWXC-1700 type relay small-capacity load reliability test system of the present invention includes an adjustable load system 7 and a signal conditioning circuit 5 connected in sequence, an isolation sampling circuit 4, a high-speed acquisition board 2, and an industrial computer. Control module 1, control board 3 and solid state relay group 9. The input end of the signal conditioning circuit 5 is connected to contact circuits 10 of a plurality of test relays, the adjustable load system 7 is connected to the contact circuits 10 of the test relays, and the contact circuits 10 of the test relays are Also connect the programmable load power supply 6. The solid-state relay group 9 is composed of a plurality of solid-state relays, and each solid-state relay is correspondingly connected to a test relay coil 11 , and the solid-state relay group 9 is also connected to a programmable coil power supply 8 . The signal conditioning circuit 5 can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com