Complex structure reverse-flow valve core and numerical control processing method thereof

A technology with complex structures and processing methods, which is applied to valve devices, engine components, mechanical equipment, etc., can solve the problems of restricting the processing efficiency of parts, insufficient processing of products, and long cutting lines, so as to improve processing efficiency, beautiful appearance, The effect of a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

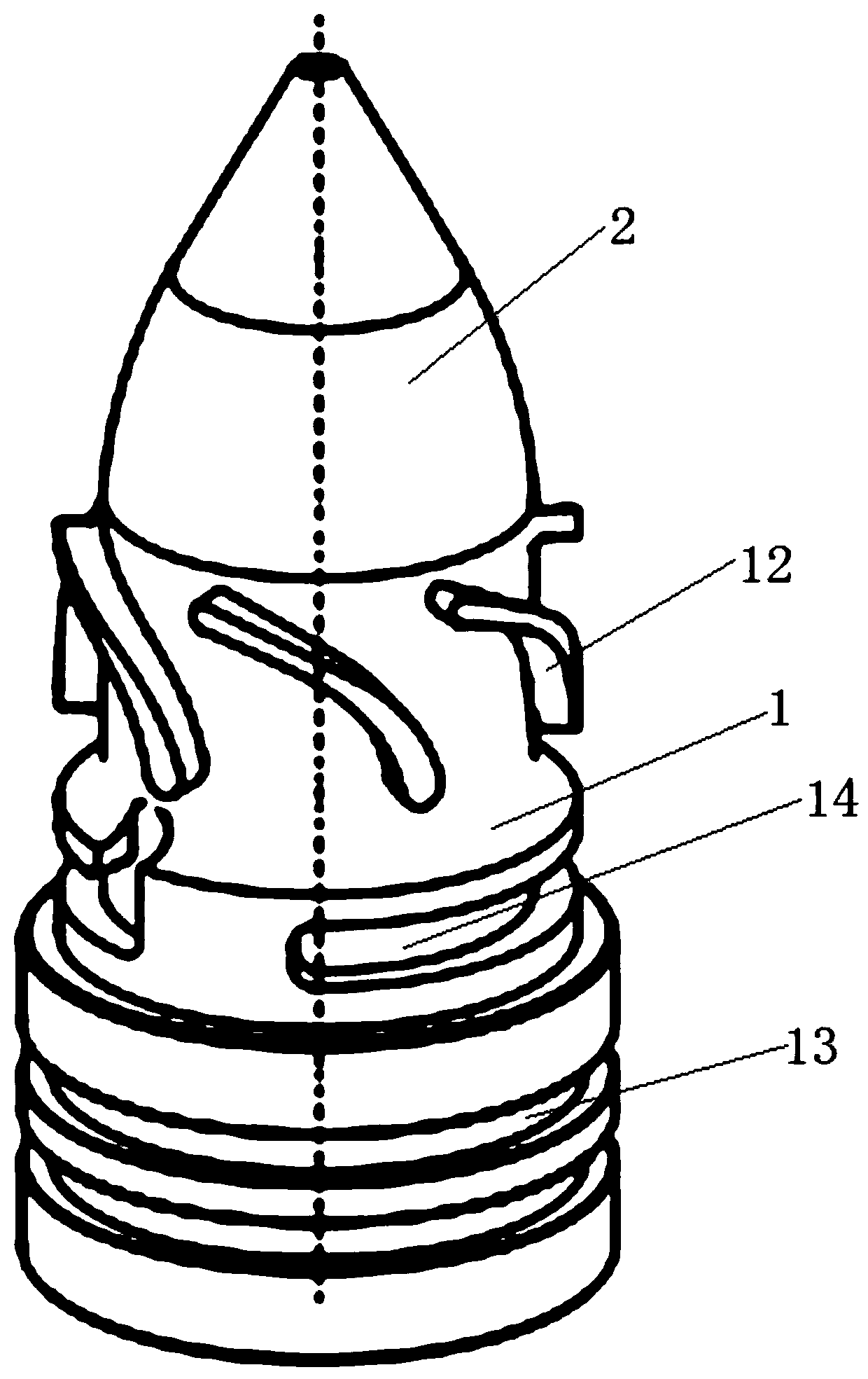

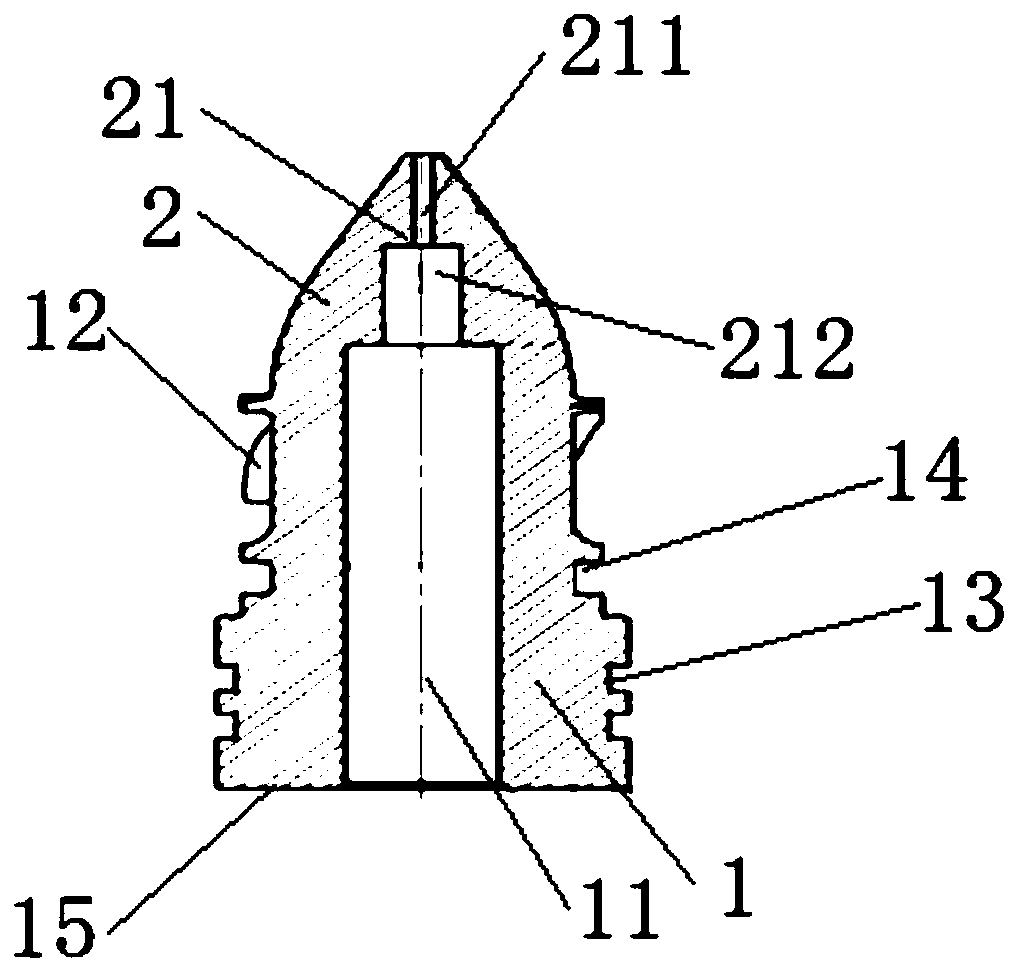

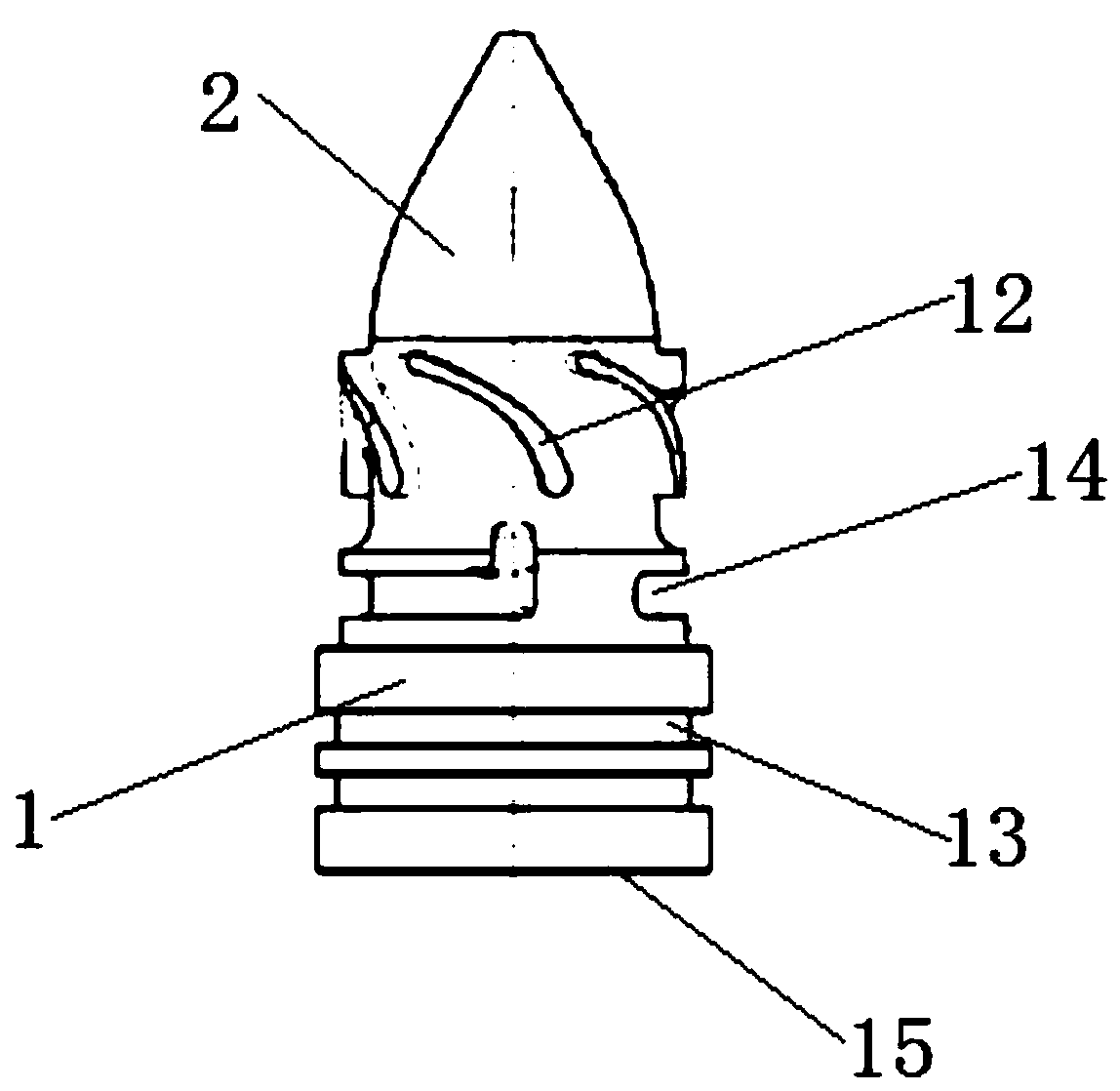

[0042] refer to Figure 1-Figure 3, this embodiment provides a reverse flow valve core with a complex structure, including a valve body 1 and a valve head 2, the valve head 2 is connected to the upper end of the valve body 1, and the valve head 2 is provided with a stepped through hole 21, the The valve body 1 is provided with a straight through hole 11 , the stepped through hole 21 communicates with the straight through hole 11 , and the valve body 1 is provided with an irregular boss 12 outside.

[0043] In this embodiment, the stepped through hole 21 includes two connected sections. The upper section is a narrow through hole 211, and the lower section is a wide through hole 212. The narrow through hole 211, wide through hole 212, and straight through hole 11 are sequentially connected. The narrow through hole 211 , the wide through hole 212 and the straight through hole 11 are all cylindrical through holes. That is, the cross-sections of the narrow through hole 211 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com