3D mechanical edge finder based on bulb universal joint

A ball joint, edge finder technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of inaccurate tool setting, workpiece error, etc. The effect of low cost, high precision, high efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

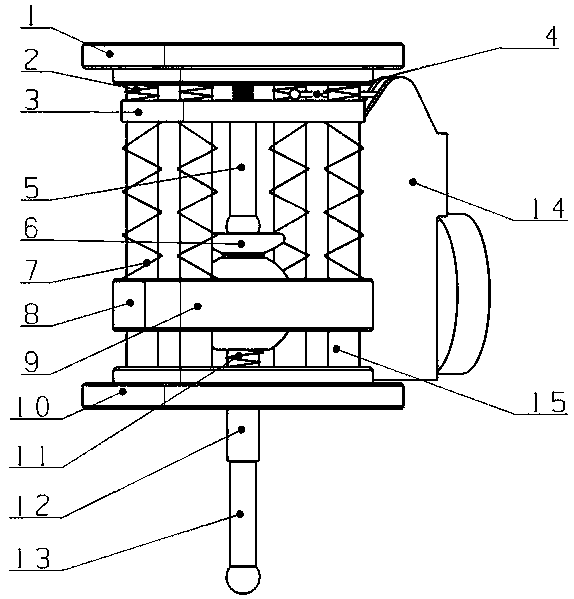

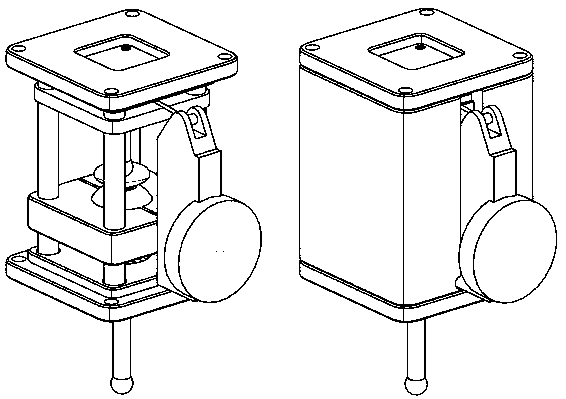

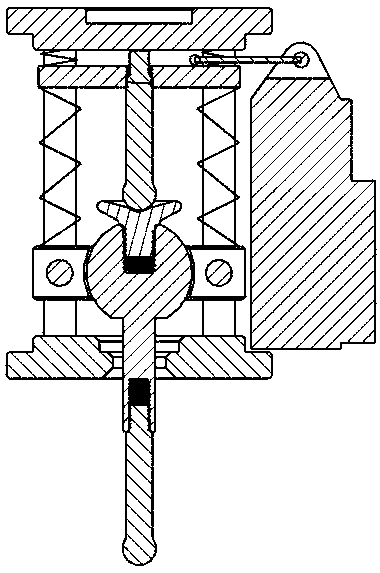

[0023] see Figure 1-6 , a 3D edge finder based on a ball joint, the edge finder includes an upper top cover 1, an upper and lower floating plate 3, an internal adjustment probe 5, a concave spherical part 6, a swing return spring 11, and a dial indicator 14 and the main body bottom plate 10, the upper top cover 1 is connected with the upper and lower floating plates 3, and the upper top cover 1 and the upper and lower floating plates 3 are also provided with a downward pressure return spring 2 and an internal adjustable gauge 4, and the internal adjustable gauge One end of the head 4 is connected to the upper and lower floating plates 3, and the other end is connected to the dial indicator 14; the internal adjustment measuring head 5 is located below the upper and lower floating plates 3, one end is connected to the lower end of the upper and lower flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com