Control method used for while-drilling tube following pile machine

A control method and technology of pipe-while-drilling, which is applied to the automatic control system of drilling, drilling equipment and methods, sheet pile walls, etc., can solve the large difference in bearing performance between individual pipe pile foundations, which is not in line with the development of building industrialization Trend, damage to pipe piles and pile driver equipment, etc., to overcome the time lag and dependence on the technical level of engineers, to facilitate accurate design, and to increase the effect of sinking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

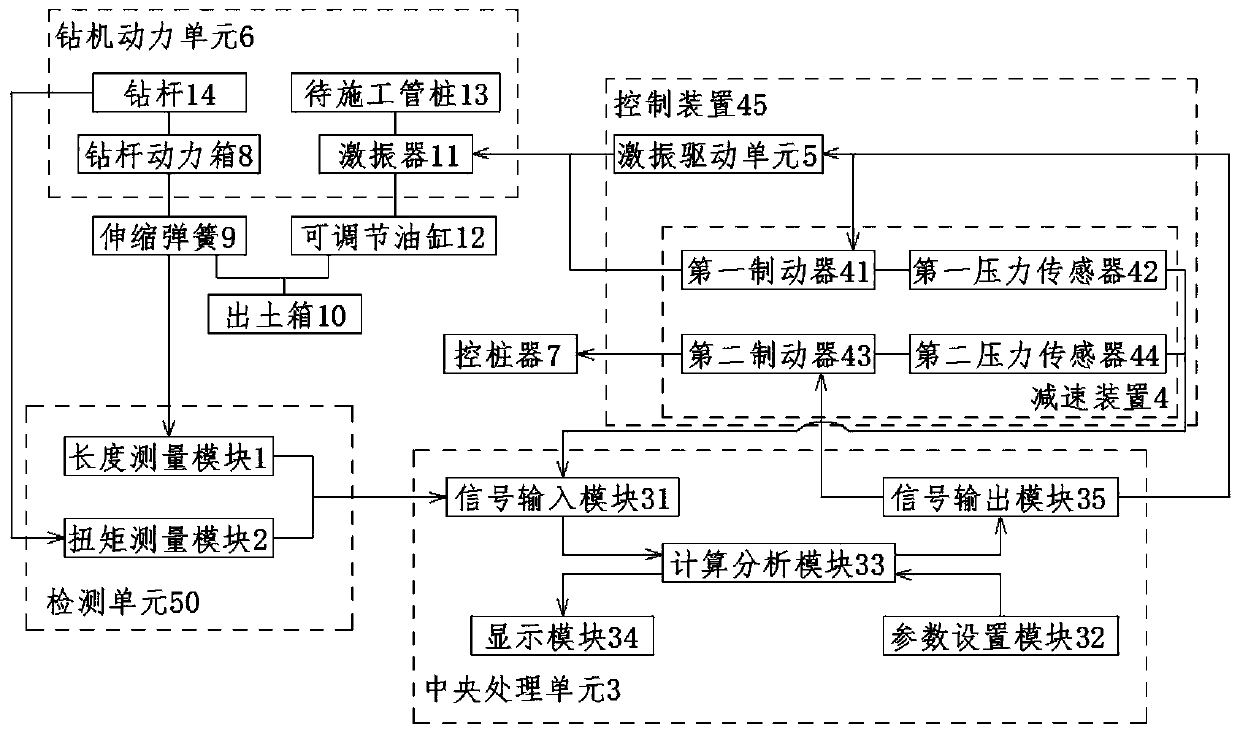

[0032] A kind of automatic control system that is used for drilling and following pipe pile machine is provided in the present embodiment, such as figure 1 As shown, it includes a detection unit 50 , a central processing unit 3 , a control device 45 and a drilling rig power unit 6 .

[0033] The drill power unit 6 includes a drill pipe 14, a drill pipe power box 8 corresponding to the drill pipe 14, a pipe pile 13 to be constructed, and a vibrator 11 corresponding to the pipe pile 13 to be constructed; The power box 8 is connected with an excavation box 10 by connecting a telescopic spring 9, and the excavation box 10 is connected with the vibrator 11 by connecting an adjustable oil cylinder 12.

[0034] The detection unit 50 is arranged between the central processing unit 3 and the drilling rig power unit 6, and is used to detect the operating parameters of the drilling rig power unit 6 and send the operating parameters to the central processing unit 3; The detection unit in...

Embodiment 2

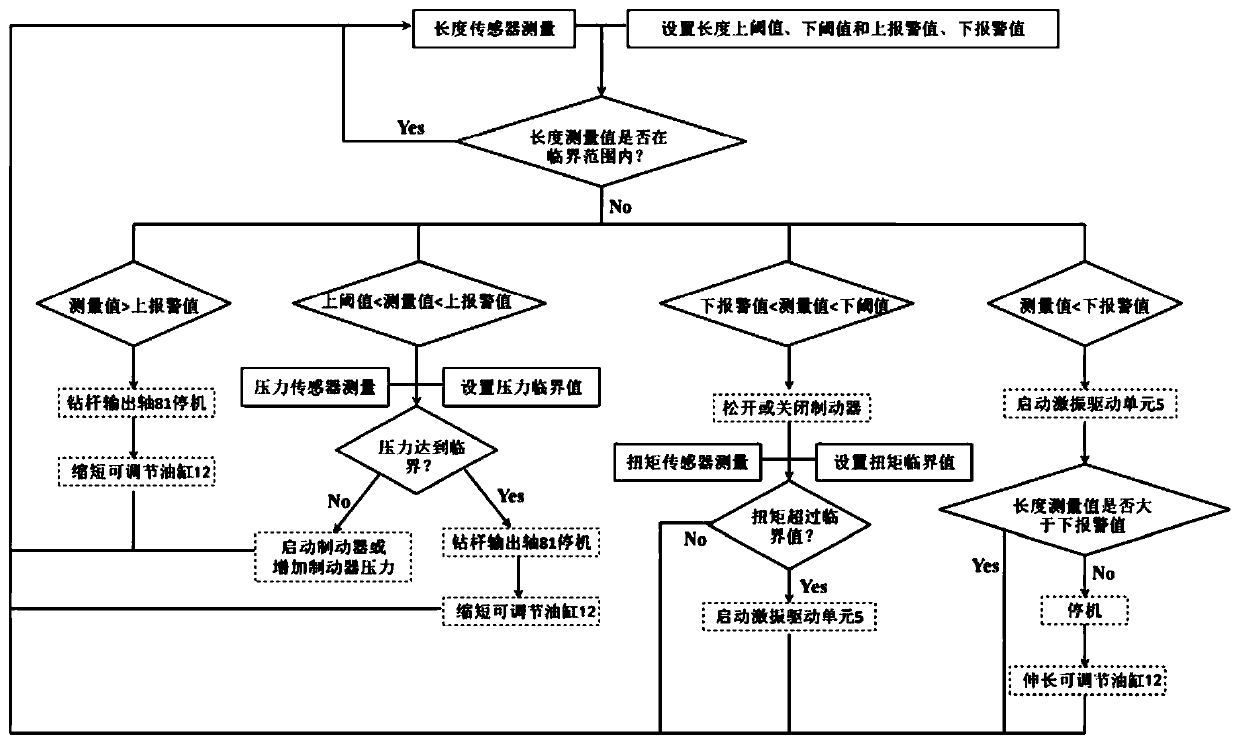

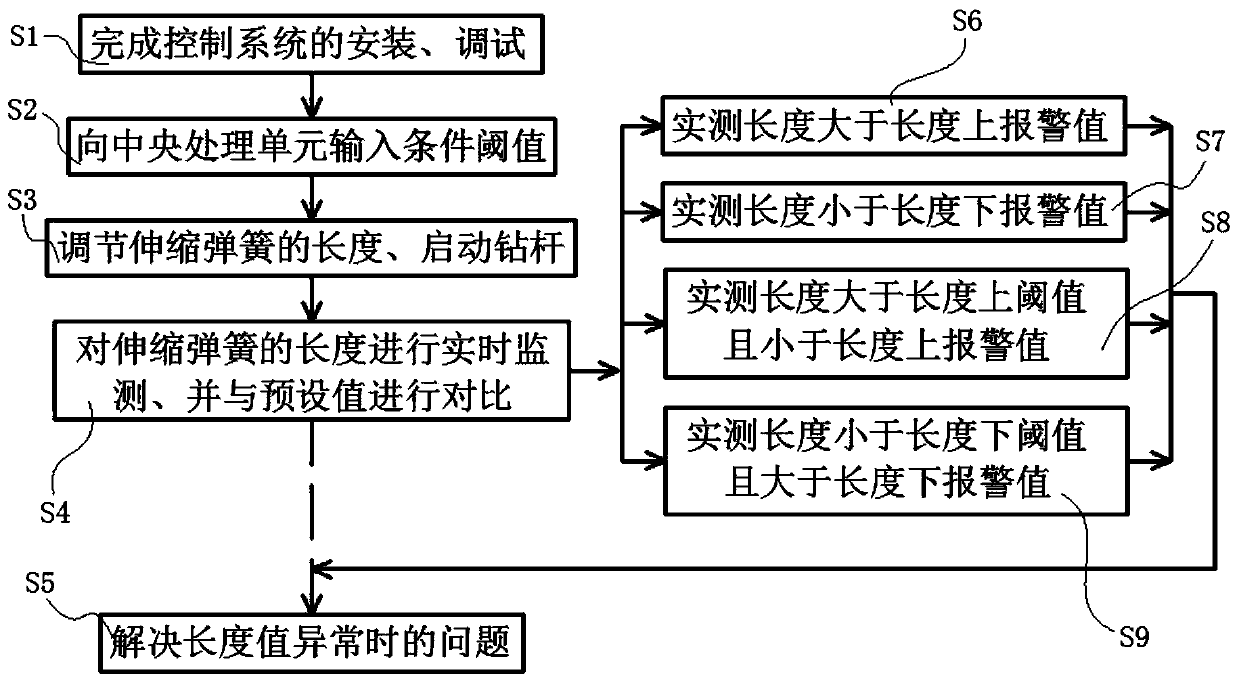

[0044] In order to facilitate the understanding of the working principle of the above-mentioned automatic control system, in this embodiment, a method such as Figure 2-Figure 3 The shown control method for drilling and following pipe pile machine includes the following steps:

[0045] S1. Complete the installation and debugging of the above-mentioned automatic control system before construction.

[0046] S2. Input to the central processing unit 3 the condition thresholds for controlling the output shaft 81 of the drill pipe power box 8, the reduction gear 4 and the excitation drive unit 5 to start and stop, including a pressure critical value, a torque early warning value, a length upper threshold, Length lower threshold, length upper alarm value, length lower alarm value and buffer time; wherein, length upper alarm value > length upper threshold > length lower threshold > length lower alarm value.

[0047] S3. Adjust the adjustable oil cylinder 12 so that the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com