Production line

A production line and linear transmission technology, which is applied in the direction of conveyors, electrolysis process, electrolysis components, etc., can solve problems such as unbalanced force on hangers, failures, and affecting the quality of electroplating, so as to improve uniformity and avoid jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

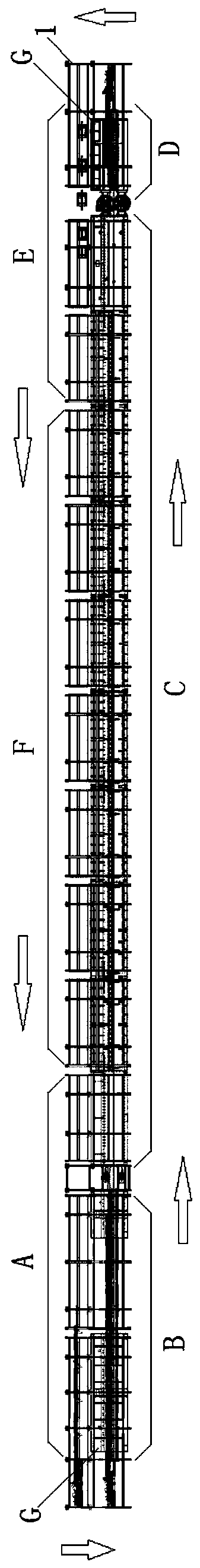

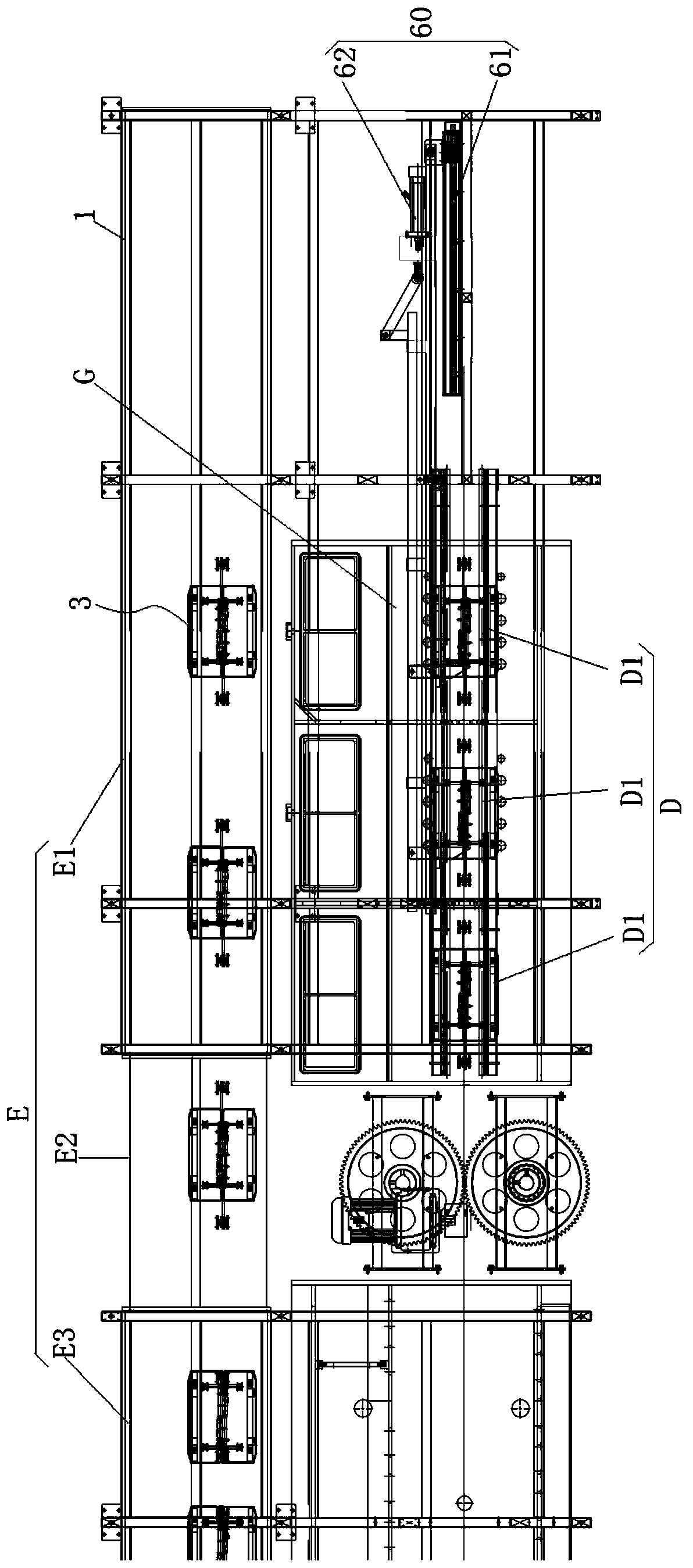

[0127] This embodiment provides a production line, such as figure 1 As shown, it includes a frame 1 , a hanger conveying system continuously erected on the frame in a ring shape, and a plurality of hangers 3 arranged on the hanger conveying system and driven for intermittent or continuous operation. The frame 1 is in the form of a gantry structure, and a plurality of racks are arranged at intervals along the running path of the hanger 3 . Several working sections are set on the rack conveying system, such as figure 1 As shown, the running direction of the hanger 3 is counterclockwise, and the running path along the hanger 3 includes: loading section A, pre-processing section B, electroplating section C, post-processing section D, unloading section E and the hanging piece Temporary section F. Specifically, in this embodiment, distributed along the running direction of the hanger 3, the hanger temporary storage section F sequentially includes a hanger storage position and a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com