Phase-change energy-storage temperature-regulating slurry powder

A technology of phase change energy storage and phase change temperature, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high temperature resistance, easy cracking, heat storage capacity to be further improved, etc., to improve heat resistance performance, improved thermal insulation, and improved thermal cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

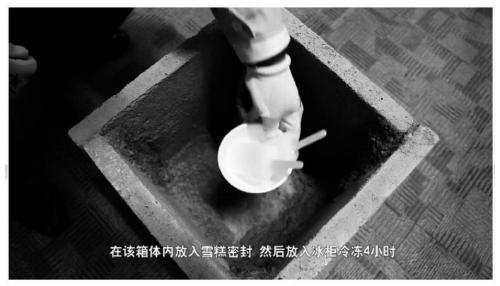

Image

Examples

Embodiment 1

[0031] A phase-change energy-storage temperature-regulating slurry powder, made of the following components by weight: 25 parts of microcrystalline wax, 15 parts of n-decanoic acid, 12 parts of flame retardant, 0.2 part of antifungal agent, 0.2 part of chlorinated Sodium, 30 parts of closed-cell vitrified microspheres with an average particle size of 0.6mm;

[0032] The flame retardant is made of active magnesium hydroxide, microcapsule red phosphorus, antimony trioxide, and zinc borate in a mass ratio of 50:8:6:3; the antifungal agent is made of sorbic acid and benzoic acid in a mass ratio Made for a 4:1 ratio.

Embodiment 2

[0034] A phase-change energy-storage temperature-regulating slurry powder, which is made of the following components in parts by weight: 25-35 parts of microcrystalline wax, 15-25 parts of n-decanoic acid, 12-16 parts of flame retardant, 0.2-0.8 parts of Antifungal agent, 0.2-0.8 parts of potassium chloride, 35 parts of closed-cell vitrified microspheres with an average particle size of 0.7mm;

[0035] The flame retardant is made of active magnesium hydroxide, microcapsule red phosphorus, antimony trioxide, and zinc borate in a mass ratio of 50:10:8:5; the antifungal agent is made of sorbic acid and benzoic acid in a mass ratio Made for a 5:1 ratio.

Embodiment 3

[0037] A phase-change energy-storage temperature-regulating slurry powder, made of the following components by weight: 35 parts of microcrystalline wax, 25 parts of n-decanoic acid, 16 parts of flame retardant, 0.8 part of antifungal agent, and 0.8 part of ammonium sulfate , 40 parts of closed-cell vitrified microspheres with an average particle size of 0.8mm;

[0038] Among them, the flame retardant is made of active magnesium hydroxide, microcapsule red phosphorus, antimony trioxide, and zinc borate in a ratio of 50:12:10:6 by mass; the antifungal agent is made of sorbic acid and benzoic acid by mass Made in a ratio of 6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com