Light rubber boot vamp rubber compound

A kind of rubber compounding, lightweight technology, applied in the application, clothing, footwear and other directions, can solve the problems of unsatisfactory mechanical properties, inconvenient wearing, impact of protective operations, etc., to achieve good boot surface stiffness and light specific gravity. , the effect of small calendering shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

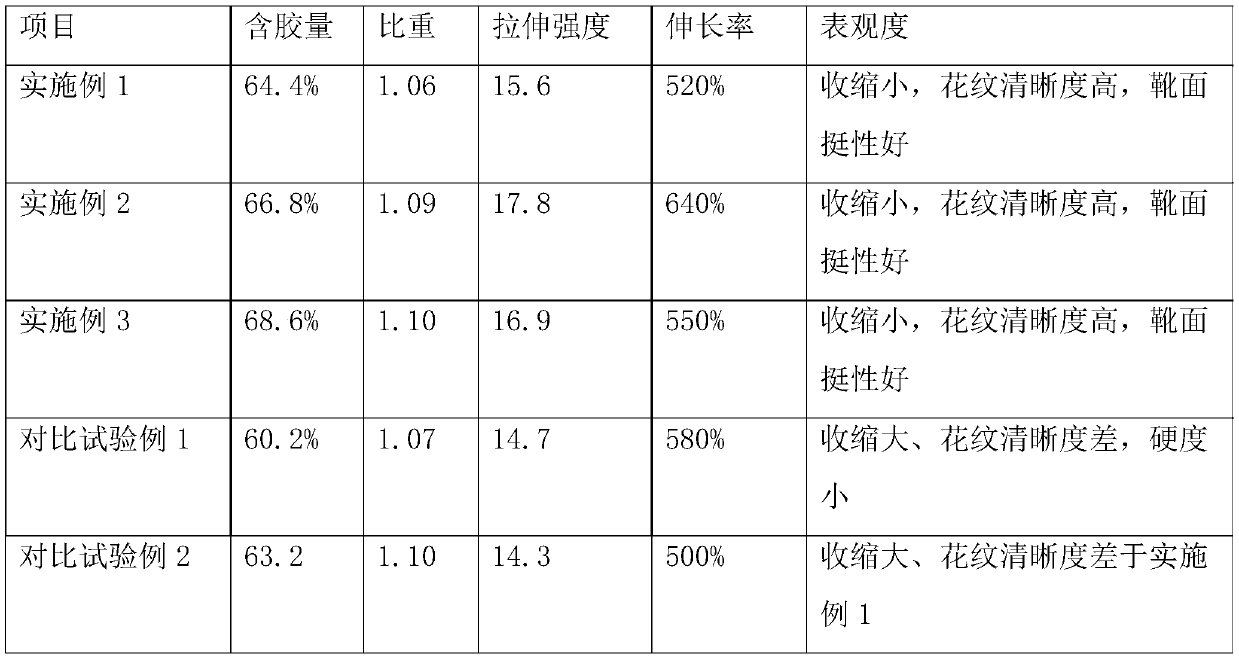

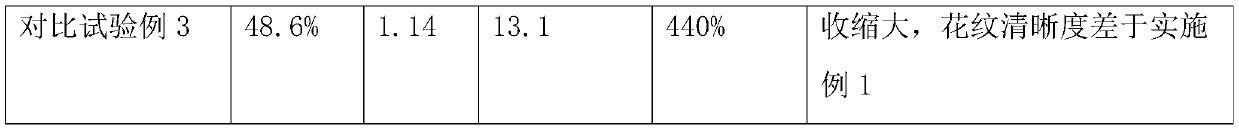

Embodiment 1

[0016] The rubber compound for the upper surface of lightweight rubber boots of this embodiment comprises the following components in parts by weight: 90 parts of natural rubber, 5 parts of high styrene rubber, 5 parts of thermoplastic styrene-butadiene rubber, 1.5 parts of sulfur, 1.0 parts of stearic acid, 2 parts of active zinc oxide, 0.8 parts of anti-aging agent MB, 0.8 parts of anti-aging agent 264, 20 parts of light white carbon black, 25 parts of hollow glass microspheres, 2 parts of phenolic resin, 1.5 parts of accelerator DM, Accelerator D 0.8 parts. The specific gravity of the light white carbon black is 1.2-1.5, the specific gravity of the hollow glass microspheres is 0.18-0.21, the surface of the hollow glass microspheres is modified by a coupling agent, and the hollow glass microspheres are from Zhejiang The hollow glass microsphere HY-5020 produced by Haiyue New Material Co., Ltd.; the light white carbon black is the light white carbon black YH350 produced by Fu...

Embodiment 2

[0018] The rubber compound for the upper surface of lightweight rubber boots of this embodiment comprises the following components in parts by weight: 80 parts of natural rubber, 10 parts of high styrene rubber, 10 parts of thermoplastic styrene-butadiene rubber, 2.5 parts of sulfur, 2.0 parts of stearic acid, 4 parts of active zinc oxide, 1.5 parts of anti-aging agent MB, 1.5 parts of anti-aging agent 264, 25 parts of light white carbon black, 30 parts of hollow glass microspheres, 8 parts of phenolic resin, 1.2 parts of accelerator DM, 0.5 parts of accelerator D, the specific gravity of the light white carbon black is 1.2-1.5, the specific gravity of the hollow glass microspheres is 0.18-0.21, the surface of the hollow glass microspheres is modified by a coupling agent, the The hollow glass microspheres are hollow glass microspheres HY-5020 produced by Zhejiang Haiyue New Material Co., Ltd.; the light white carbon black is light white carbon black YH350 produced by Fujian Nan...

Embodiment 3

[0020] The mixed rubber compound for the upper surface of lightweight rubber boots of this embodiment, the rubber raw material comprises the following components in parts by weight: 70 parts of natural rubber, 8 parts of high styrene rubber, 8 parts of thermoplastic styrene-butadiene rubber, 1.8 parts of sulfur, 1.3 parts of stearic acid, 2 parts of active zinc oxide, 0.8 parts of anti-aging agent MB, 0.8 parts of anti-aging agent 264, 45 parts of light white carbon black, 40 parts of hollow glass microspheres, 4 parts of phenolic resin, 0.8 parts of accelerator DM, Accelerator D 0.4 parts The specific gravity of the light white carbon black is 1.2-1.5, the specific gravity of the hollow glass microspheres is 0.18-0.21, the surface of the hollow glass microspheres is modified by a coupling agent, and the hollow glass microspheres The glass microspheres are hollow glass microspheres HY-5020 produced by Zhejiang Haiyue New Material Co., Ltd.; the light white carbon black is light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com