Method and device for reducing use amount of sleeves

A technology of usage volume and sleeves, which is applied in rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problems of increased production costs and high sleeve usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

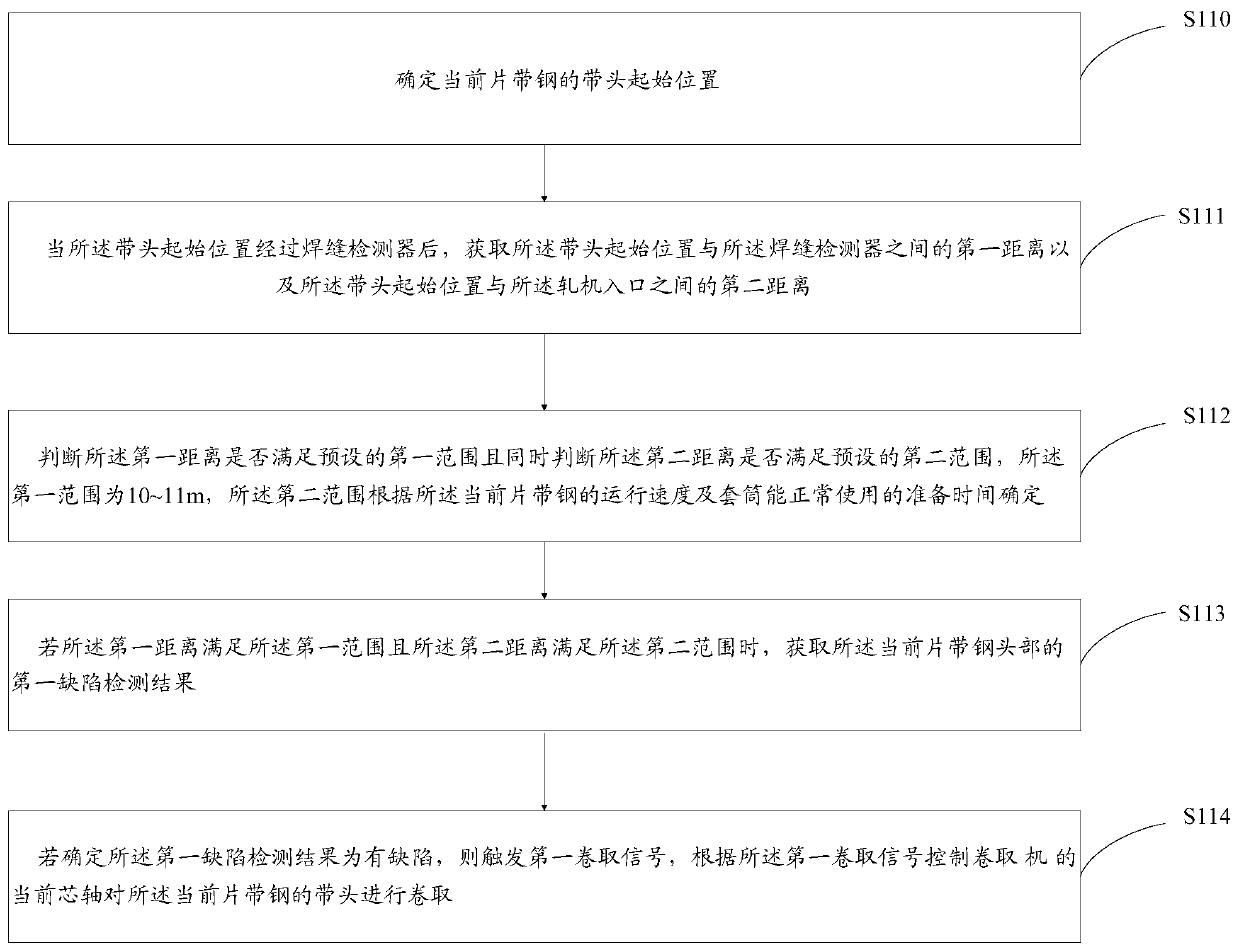

[0047] This embodiment provides a method for reducing the amount of sleeve used, which is applied to the continuous acid rolling production line. The continuous acid rolling production line is arranged in sequence according to the running direction of the strip: pickling equipment, surface defect detector, trimming machines, weld detectors, loopers, rolling mills and coilers; such as figure 1 As shown, the methods include:

[0048] S110. Determine the starting position of the strip head of the current strip.

[0049] In practical application, through the analysis of production data and the accumulation of production experience, it is found that the defects of raw materials that do not meet the rolling requirements are mainly concentrated in the head and tail. Therefore, in this step, the starting position of the strip head of the current strip is determined.

[0050] Here, since the raw material coil is formed by welding together multiple pieces of steel strip, when determinin...

Embodiment 2

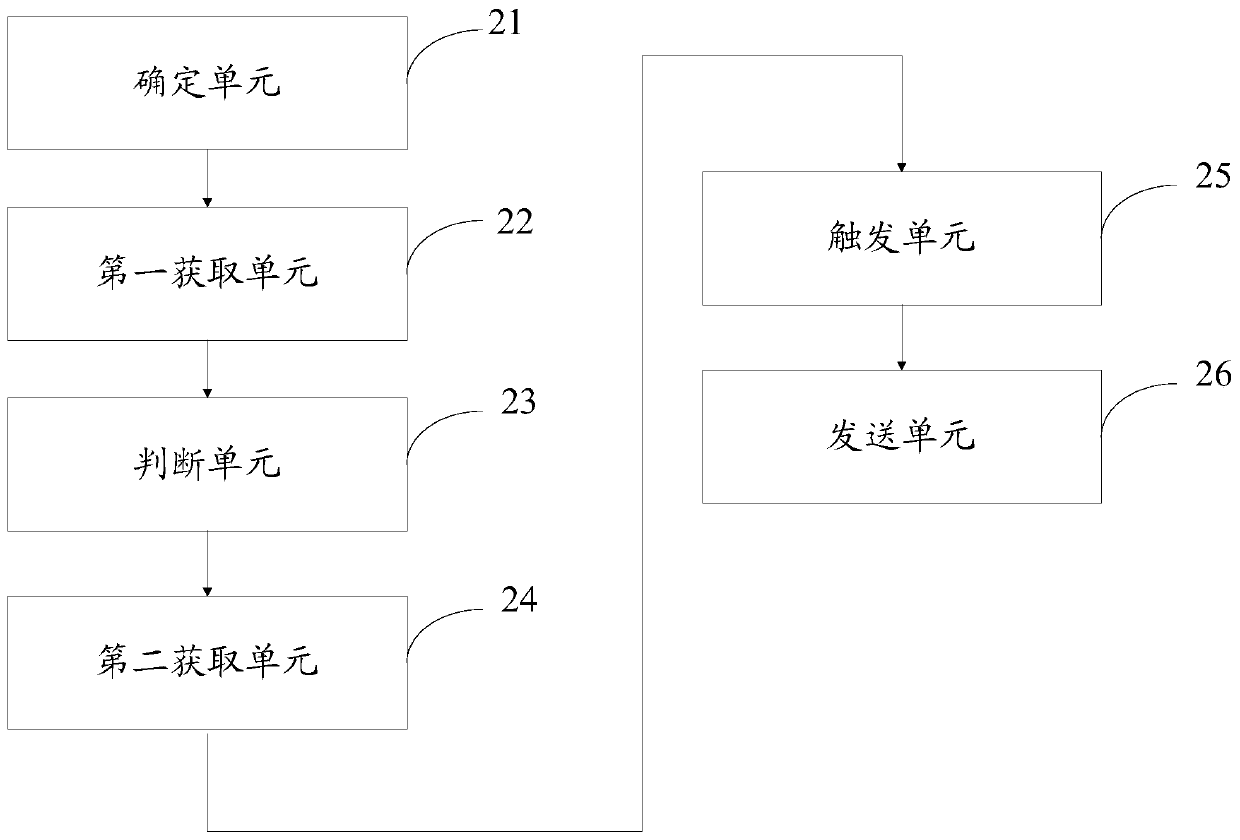

[0107] This embodiment provides a device for reducing the amount of sleeve used, which is applied to the continuous acid rolling production line. The continuous acid rolling production line is arranged in sequence according to the running direction of the strip: pickling equipment, surface defect detector, Edge trimmers, weld detectors, loopers, rolling mills and coilers; e.g. figure 2 As shown, the device includes: a determining unit 21, a first acquiring unit 22, a judging unit 23, a second acquiring unit 24 and a triggering unit 25; wherein, the determining unit 21 is used to determine the starting position of the tape head of the current strip;

[0108] The first acquiring unit 22 is configured to acquire the first distance between the starting position of the tape head and the weld seam detector and the distance between the starting position of the tape head and the weld seam detector after the starting position of the tape head passes the weld seam detector. a second di...

Embodiment 3

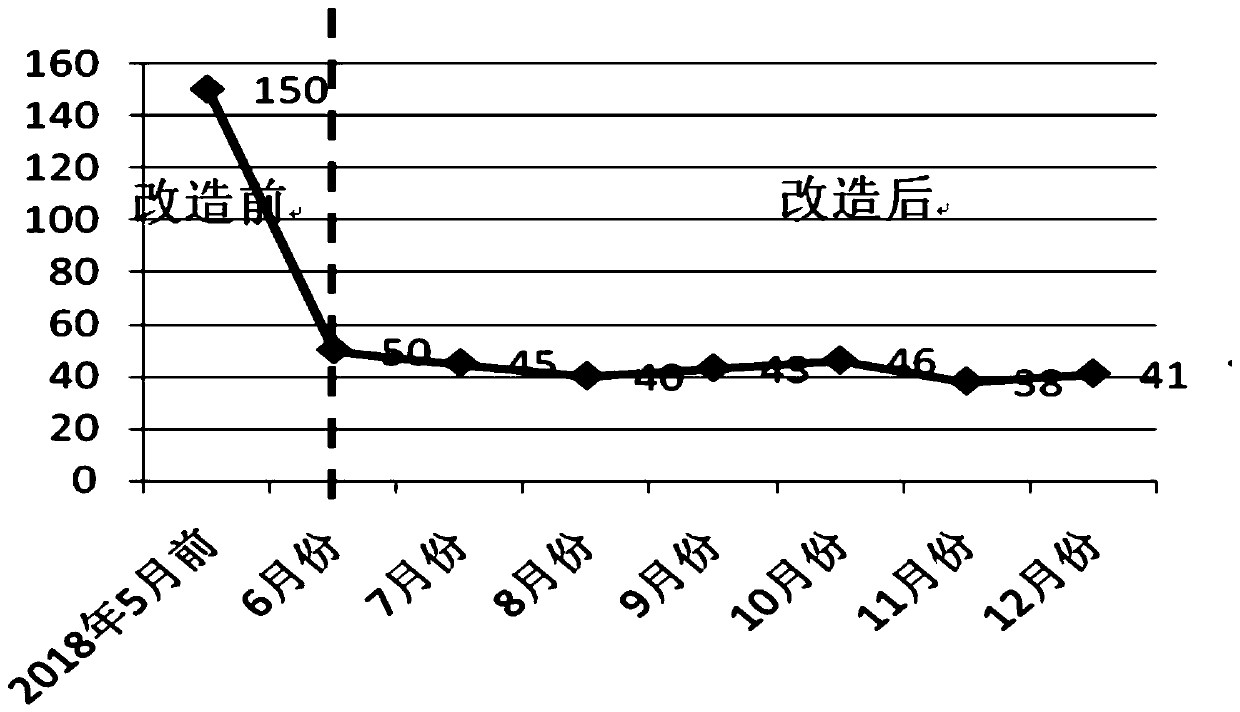

[0165] In practical application, when using the method provided in Example 1 to coil the steel strip on the acid tandem rolling production line of a certain steel plant, the sleeve usage is as shown in Table 1 and image 3 Shown:

[0166] Table 1

[0167] Effect comparison Before renovation (June and July) June july The number of sleeves consumed per month (pieces) 150 50 45

[0168] From Table 1 and image 3 It can be seen that the amount of sleeve usage is significantly reduced. image 3 middle, It is the number of sleeves used per month.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com