A cleaning and draining system for mechanical parts processing

A technology for mechanical parts and draining, which is applied in the field of cleaning and drying equipment for the processing of automotive mechanical parts, can solve the problems of low work efficiency, general cleaning effect, and heavy drying process workload, and achieves good use effect and structural design. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

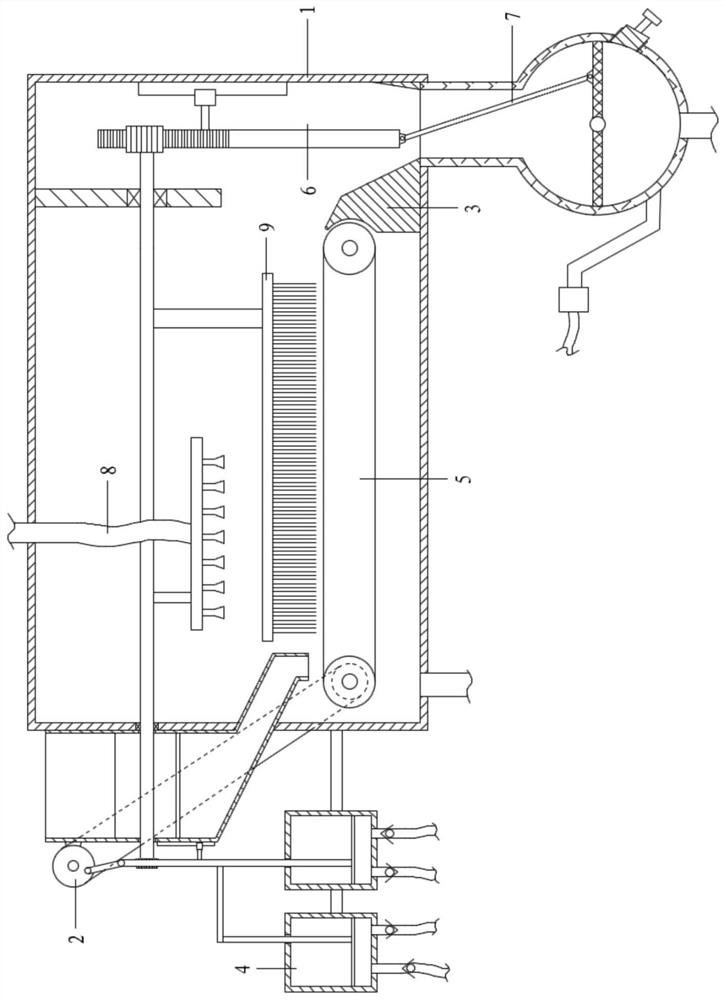

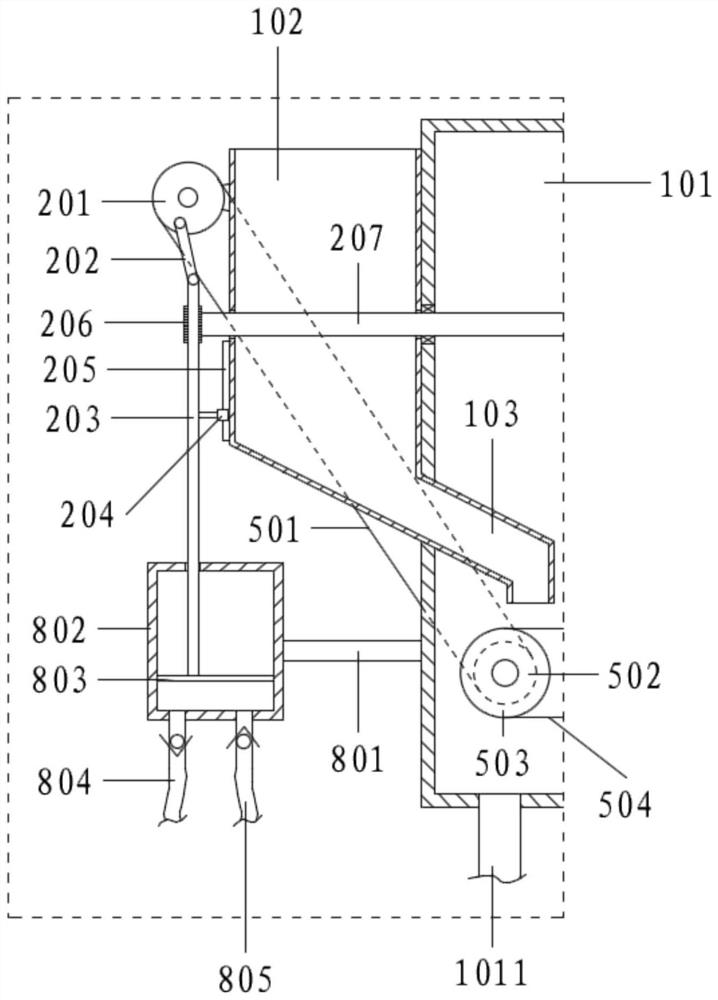

[0064] With reference to the accompanying drawings, a cleaning and draining system for processing mechanical parts includes a cavity assembly 1, a reciprocating assembly 2, a conveying assembly 5, a reciprocating assembly 6, a draining assembly 7, and a spray assembly 8;

[0065] The chamber assembly 1 includes a cleaning chamber 101, a feeding hopper 102, a feeding pipe 103, a feeding pipe 104 and a draining chamber 105; the feeding hopper 102 is fixed on the left side of the cleaning chamber 101, and the bottom end is connected with a feeding pipe 103; The material guide pipe 103 extends obliquely into the cleaning chamber 101, and the bottom outlet faces the left end of the conveying assembly 5; the conveying assembly 5 is arranged at the bottom of the cleaning chamber 101, and the right side of the conveying assembly 5 is provided with a baffle 3; There is a draining chamber 105 through the feeding pipe 104; a No. 1 reciprocating assembly 2 is arranged on the left side of t...

Embodiment 2

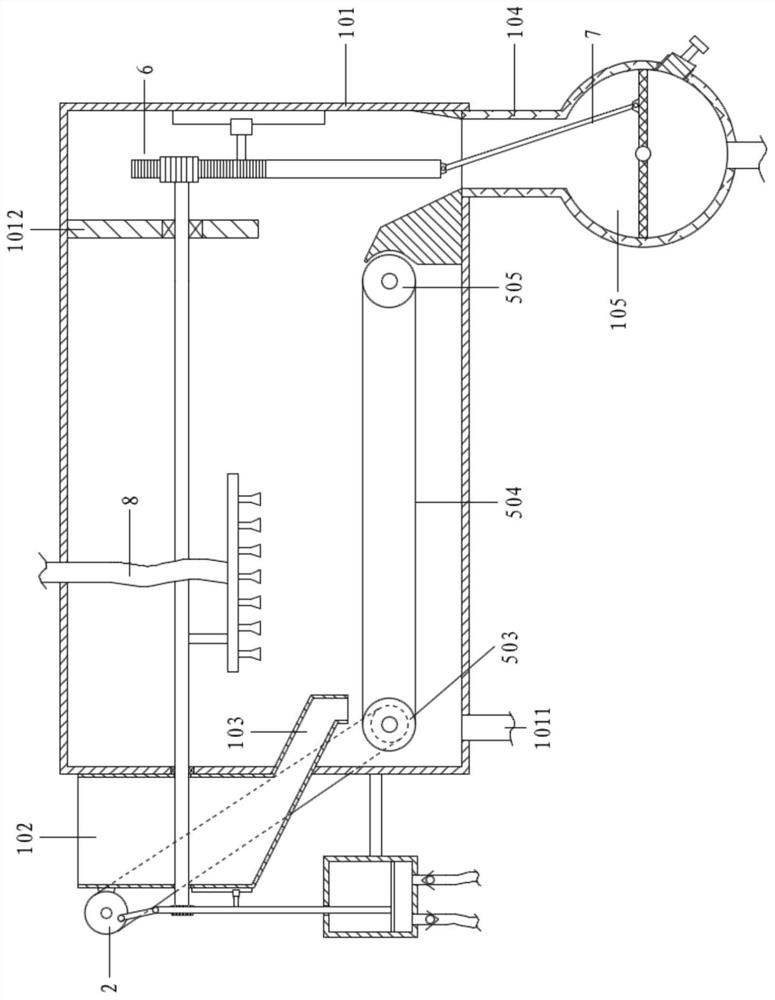

[0067] With reference to the accompanying drawings, a cleaning and draining system for processing mechanical parts includes a cavity assembly 1, a reciprocating assembly 2, a conveying assembly 5, a reciprocating assembly 6, a draining assembly 7, and a spray assembly 8;

[0068] The chamber assembly 1 includes a cleaning chamber 101, a feeding hopper 102, a feeding pipe 103, a feeding pipe 104 and a draining chamber 105; the feeding hopper 102 is fixed on the left side of the cleaning chamber 101, and the bottom end is connected with a feeding pipe 103; The material guide pipe 103 extends obliquely into the cleaning chamber 101, and the bottom outlet faces the left end of the conveying assembly 5; the conveying assembly 5 is arranged at the bottom of the cleaning chamber 101, and the right side of the conveying assembly 5 is provided with a baffle 3; There is a draining chamber 105 through the feeding pipe 104; a No. 1 reciprocating assembly 2 is arranged on the left side of t...

Embodiment 3

[0090] On the basis of the above examples,

[0091] It also includes a cleaning component 9; the cleaning component 9 is arranged in the cleaning chamber, including the third connecting rod 901, the mounting seat 902 and the bristles 903;

[0092] The mounting base 902 is arranged above the conveyor belt 504, and the top is connected with the main shaft 207 through the third connecting rod 901; the bottom surface of the mounting base 902 is equipped with bristles 903.

[0093] Specifically, the main shaft 207 is also swayed synchronously with the mounting base 902 , and the mechanical parts are scrubbed through the bristles 903 in cooperation with spraying, so as to optimize the cleaning effect on the mechanical parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com