Automatic monitoring method for plant area network

An automatic monitoring, plant area network technology, applied in data exchange networks, digital transmission systems, electrical components, etc., can solve the problem of difficult to grasp the real-time operation status of key network equipment in real time, and it is difficult to actively detect abnormal communication quality, equipment deterioration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

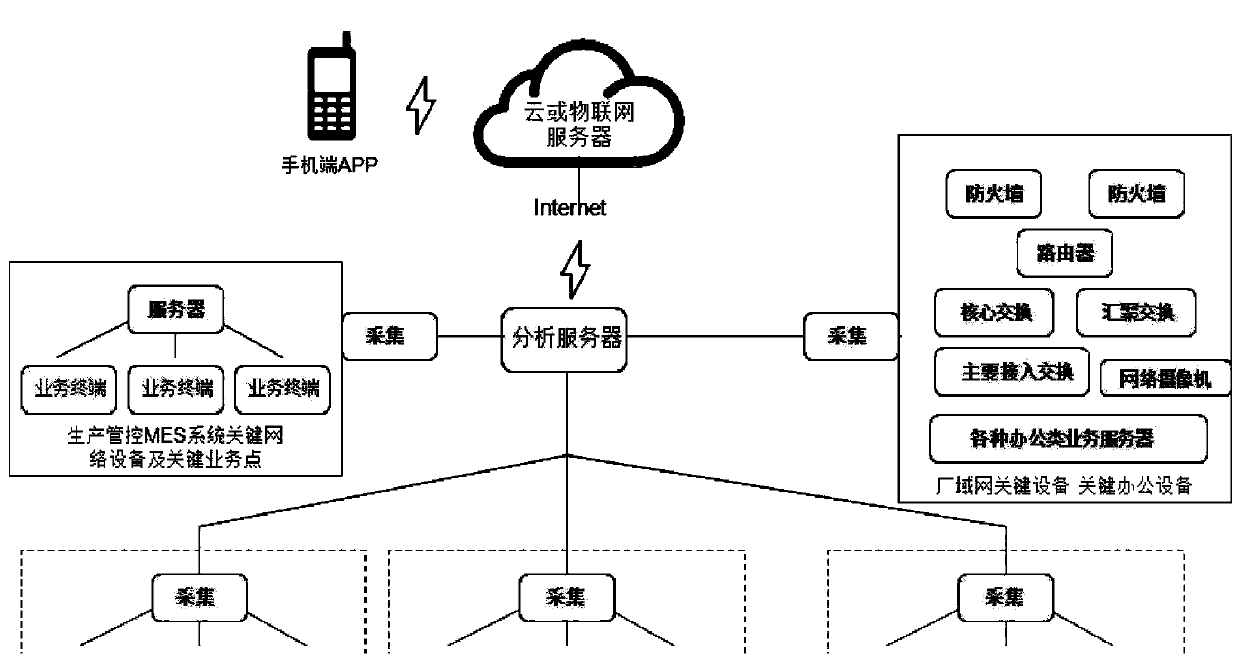

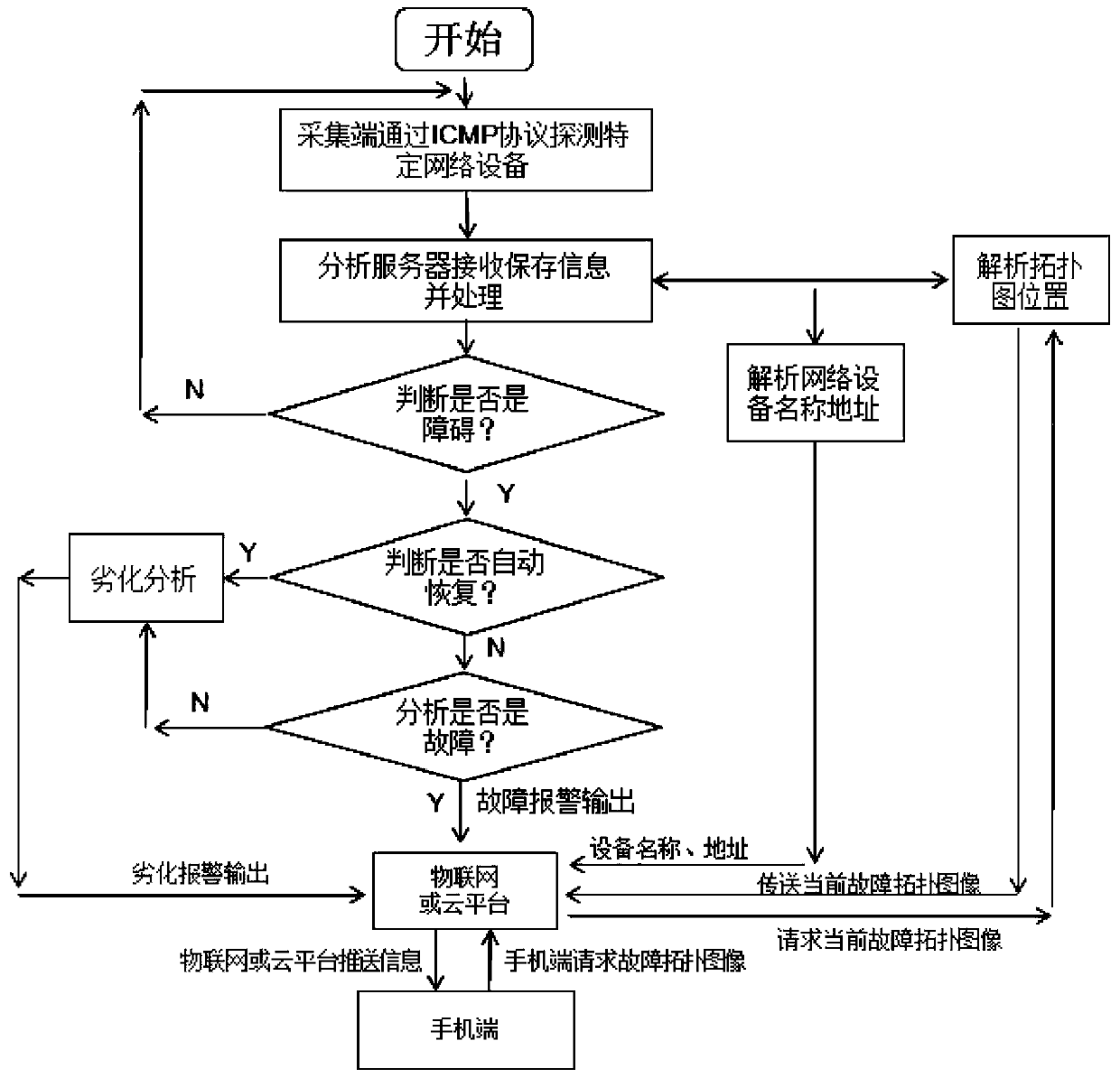

[0045] like Figure 1~2 Shown, a kind of network automatic monitoring method of plant area network of the present invention comprises the following steps:

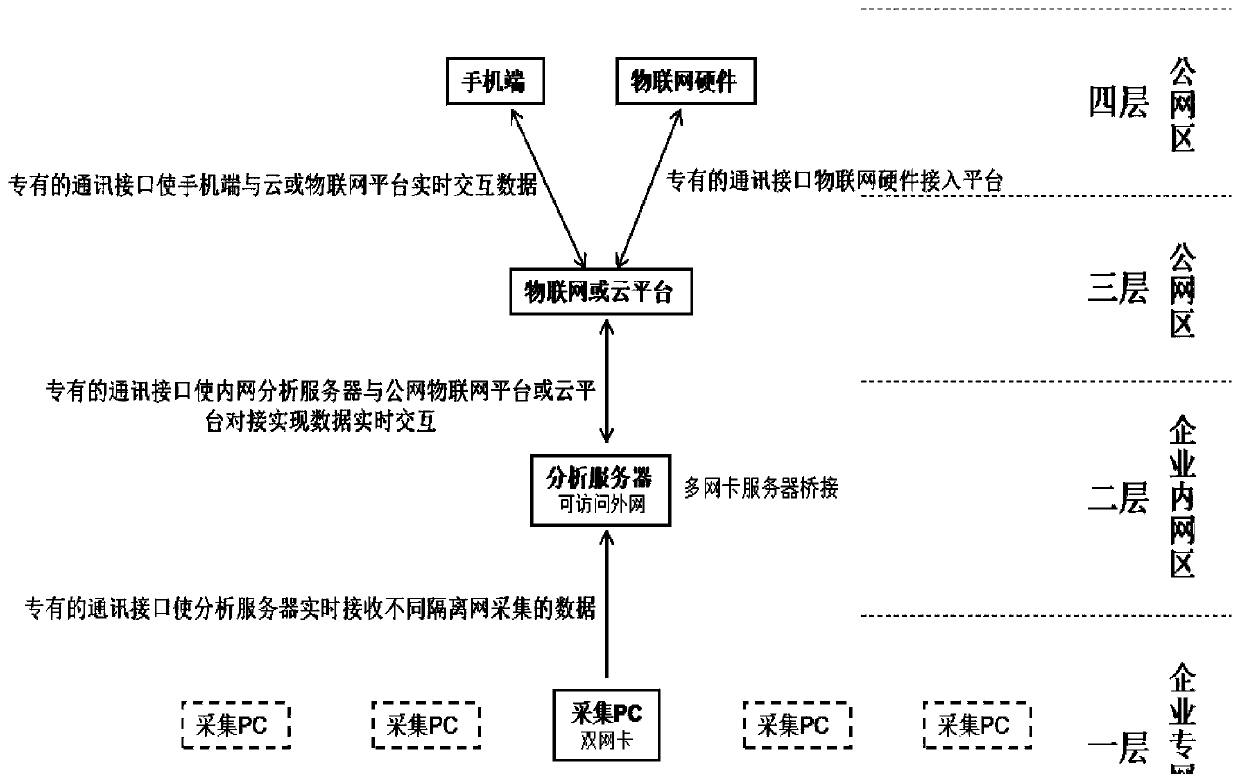

[0046] 1) Build a network architecture, establish a data collection terminal in the enterprise private network area (first floor) that the manager cares about, establish a data analysis terminal in the enterprise intranet area (second floor), and establish a data analysis terminal in the public network area through the cloud platform or the Internet of Things platform ( The third layer) realizes the data interaction between the enterprise intranet and the public network platform and the mobile terminal (fourth layer) that can realize the interaction with the cloud platform or the Internet of Things platform; the second layer and the first layer can also be the same layer.

[0047] 2) Arrange netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com