High-temperature high-stress true triaxial test device and method

A test device, true triaxial technology, applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as inability to study rock mass, buried depth, earth stress and temperature, etc., to improve the real Performance and accuracy, avoiding thermal stress concentration, and improving loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

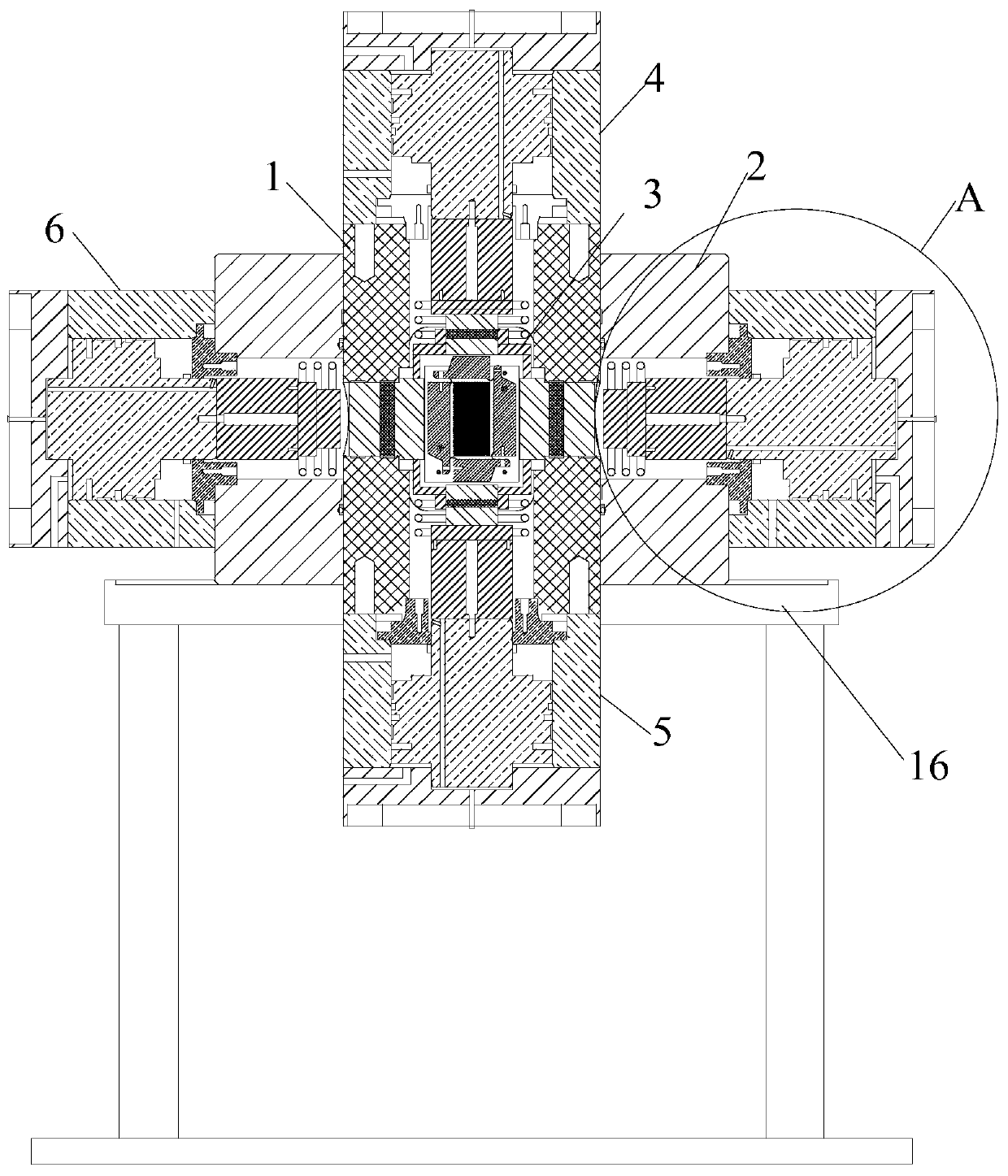

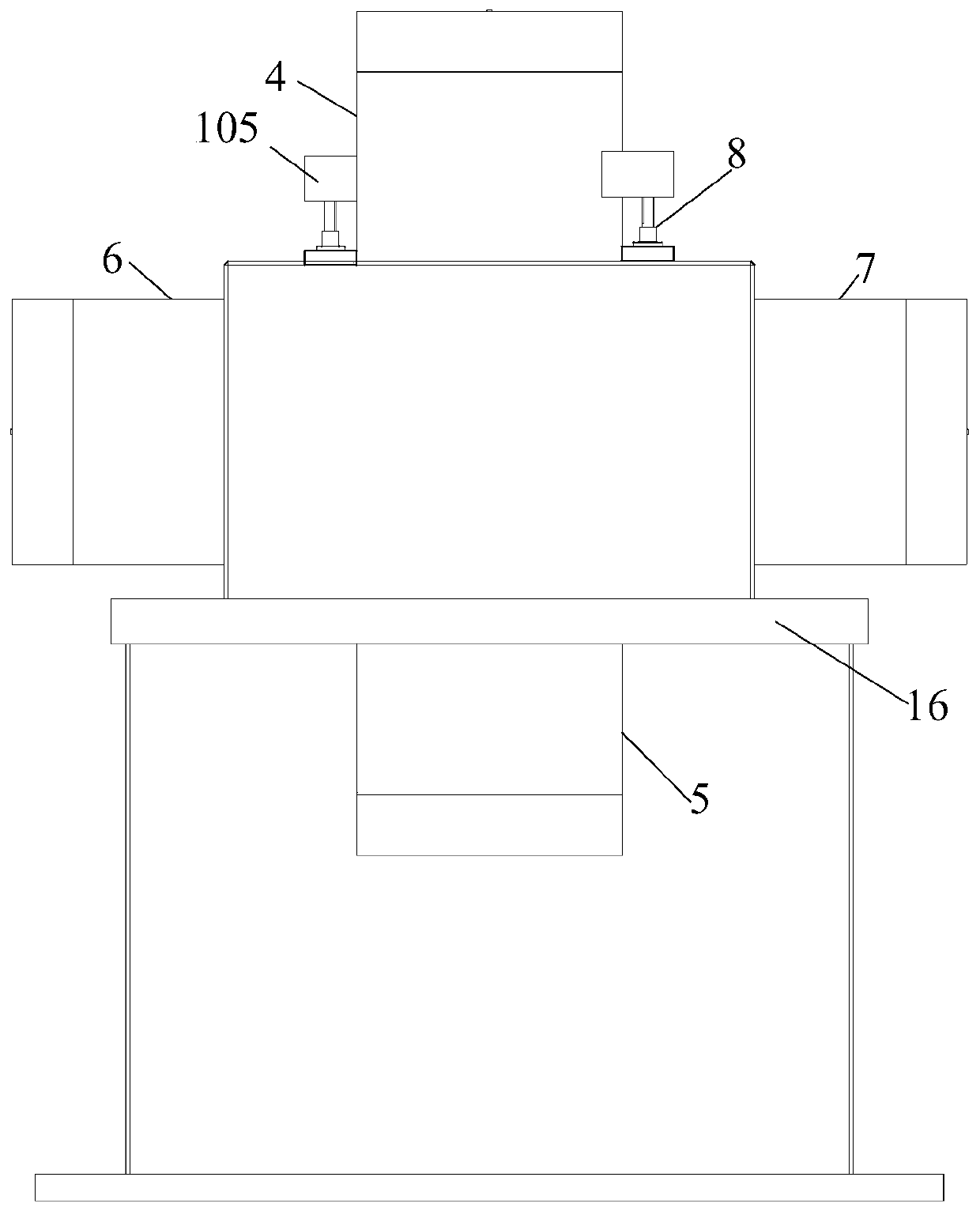

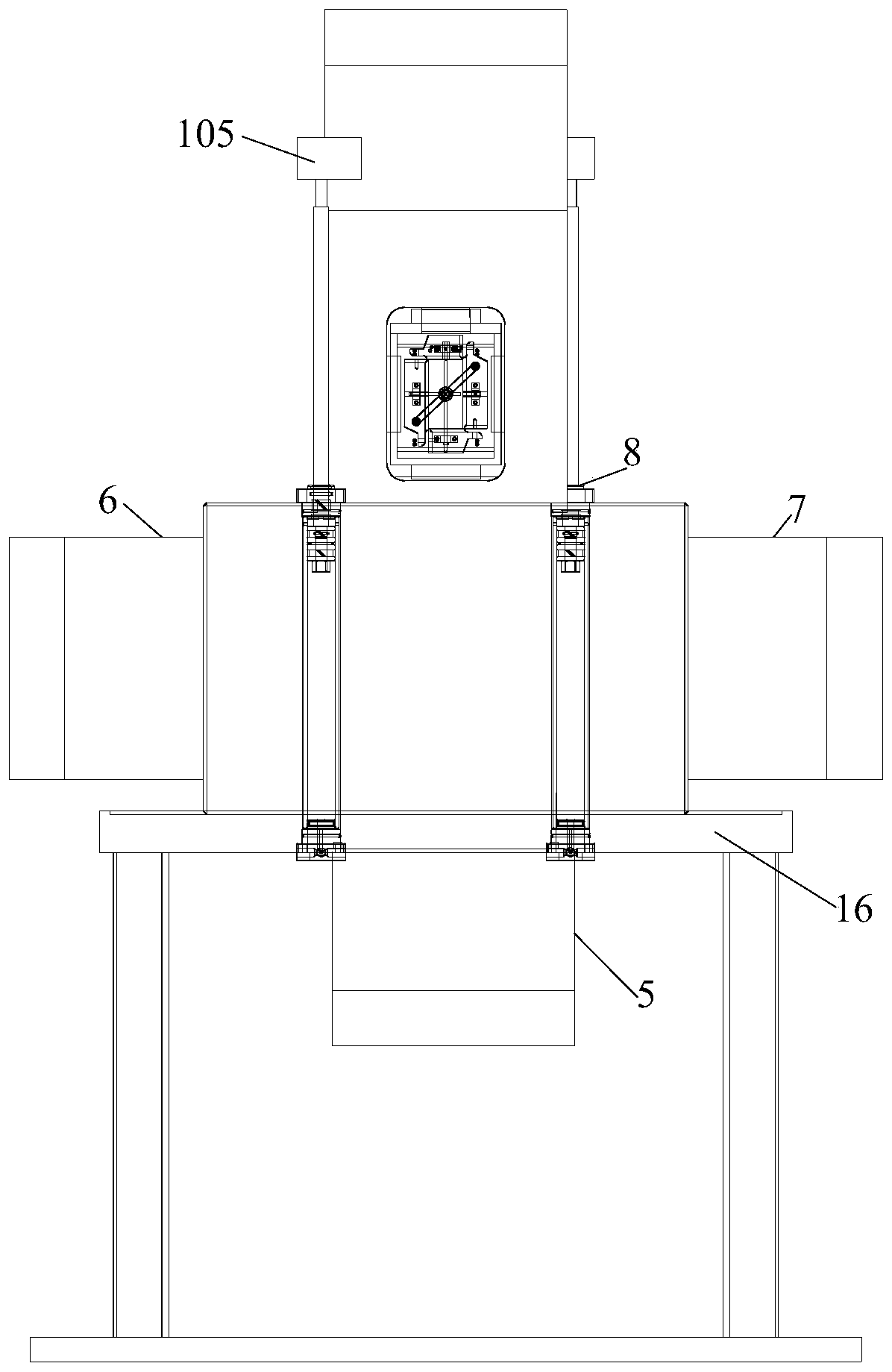

[0046] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the orientation terms such as "up", "down" and "horizontal" all start with figure 1 oriented as a reference.

[0047] Such as figure 1 As shown, the present invention provides a high temperature and high stress true triaxial test device, which includes a heating box 3, a loading chamber 2, a holder 1, a cooling assembly, a pressure head assembly, a hydraulic lift Rod 8, the first major principal stress actuator 4, the second major principal stress actuator 5, the first intermediate principal stress actuator 6 and the second intermediate principal stress actuator 7.

[0048] Wherein, the loading bin 2 is a cuboid structure, and the loading bin 2 is installed on the rigid support frame 16 horizontally and transversely, along the radial direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com