Double-cylinder-wall concrete silo slip form construction operation platform and construction method

A technology of operating platform and construction method, applied in the direction of formwork/formwork/work frame, house structure support, house structure support, etc., can solve the problems of long construction period and difficult quality control, achieve reasonable division of labor, shorten construction period, and increase the overall The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

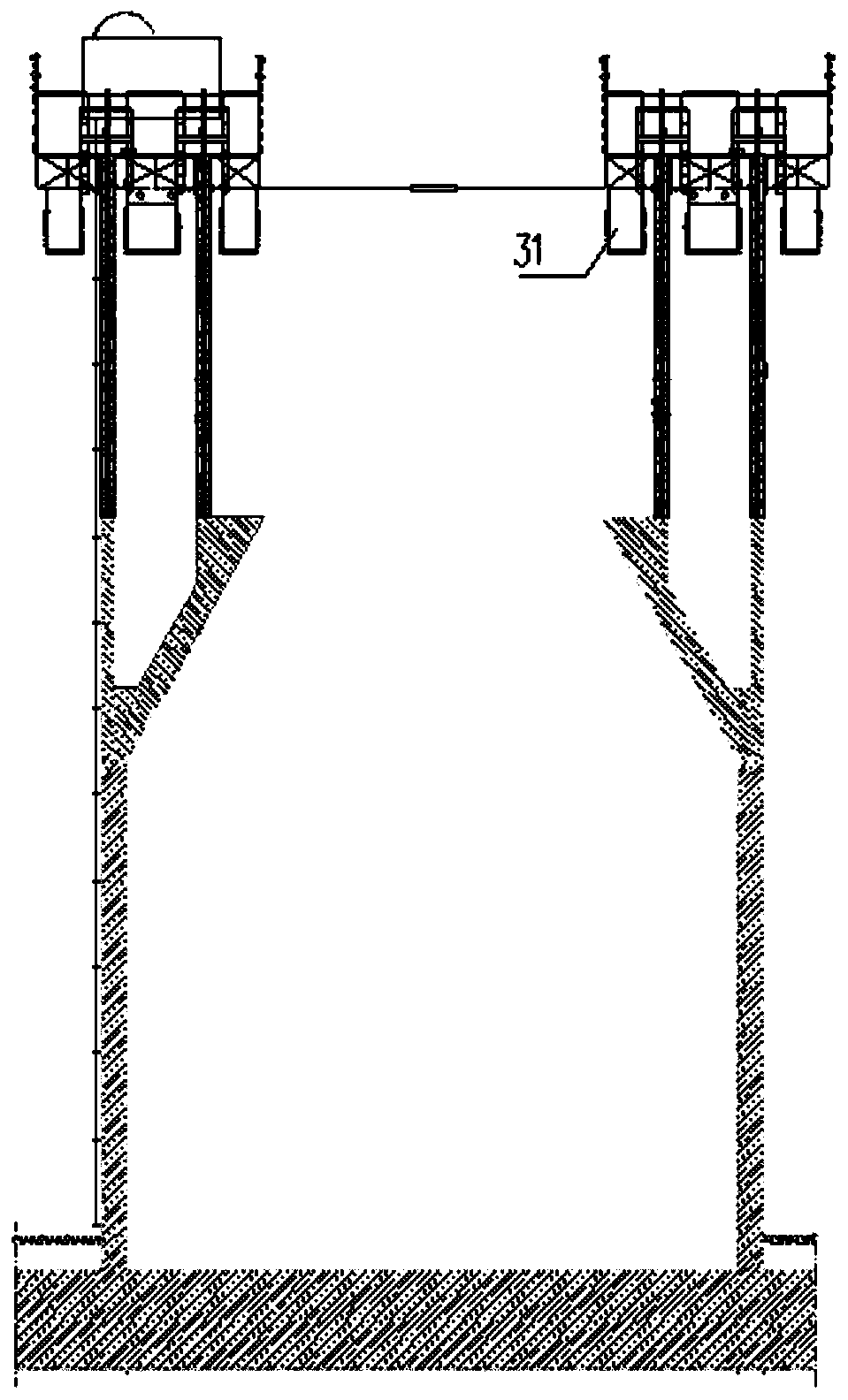

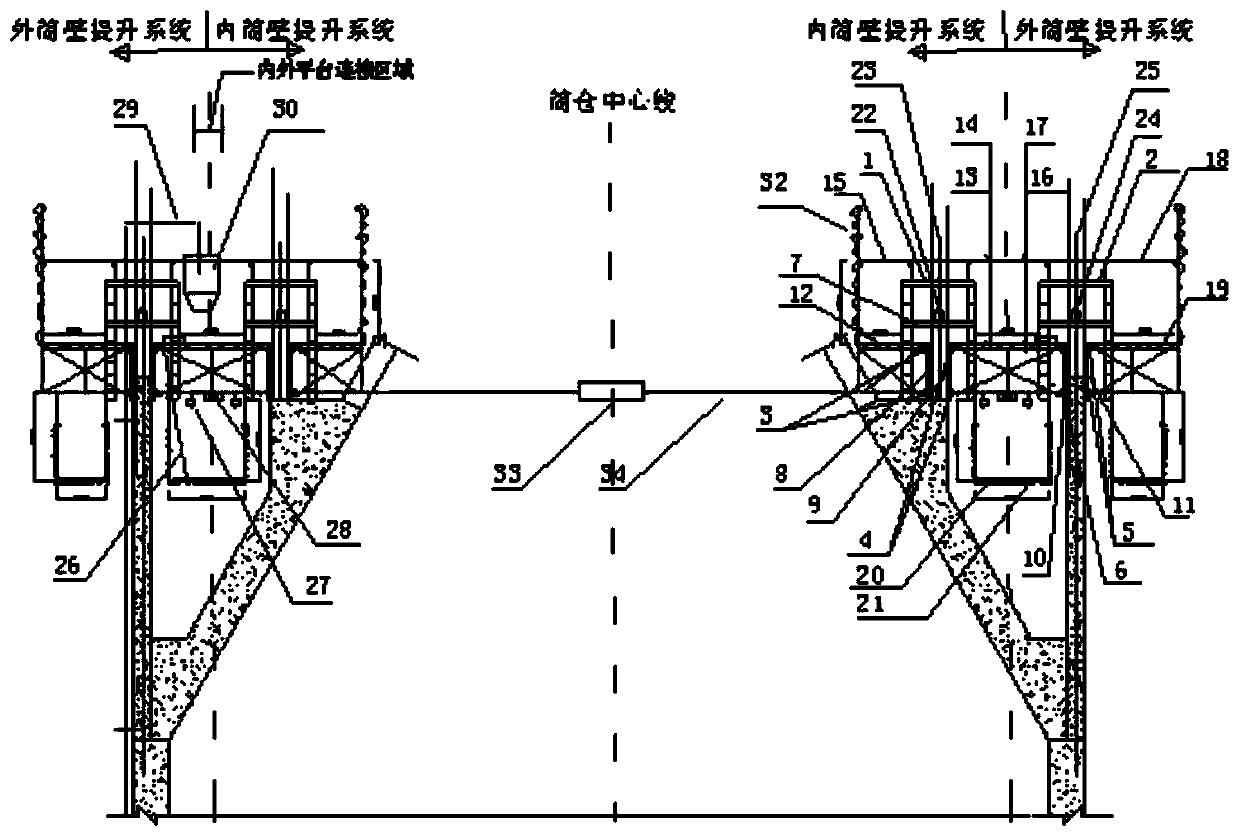

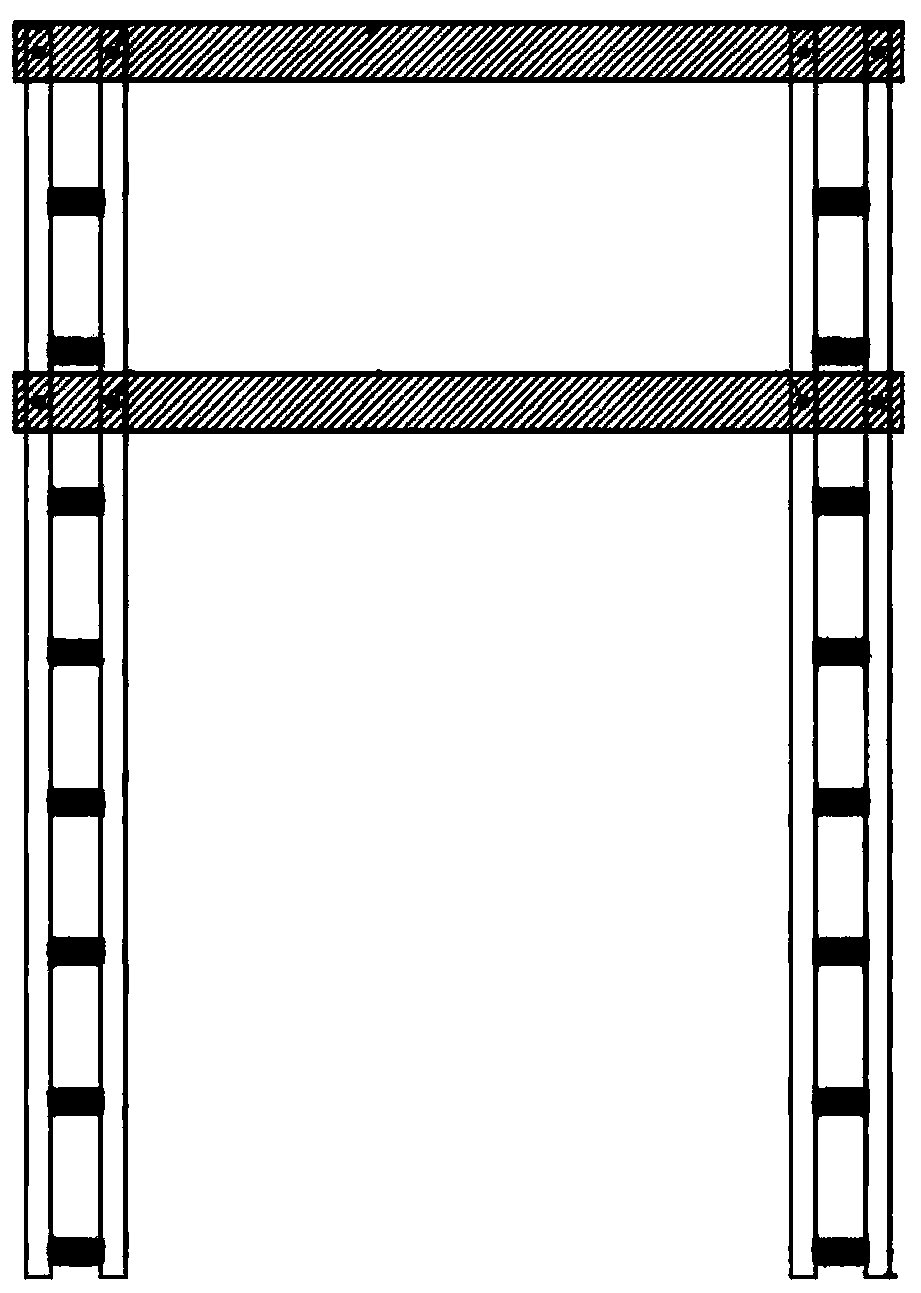

[0037] Specific embodiment one, such as Figure 1 to Figure 5 as shown,

[0038] The slipform construction operation platform for double-wall concrete silos includes: inner wall lifting system, outer wall lifting system, and public auxiliary facilities; among them,

[0039] The inner cylinder wall lifting system includes: inner cylinder wall opening frame 1, inner cylinder wall inner purlin 3, inner cylinder wall peripheral purlin 4, inner cylinder wall inner formwork 8, inner cylinder wall outer formwork 9, inner cylinder wall inner middle platform 12. Middle platform 13 outside the inner cylinder wall, upper platform 14 outside the inner cylinder wall, upper platform 15 inside the inner cylinder wall, lower platform 20 outside the inner cylinder wall, lower platform 31 inside the inner cylinder wall, hydraulic jack 22 for the inner cylinder wall, cylinder wall support rod 23.

[0040] The outer cylinder wall lifting system includes: outer cylinder wall opening frame 2, out...

specific Embodiment 2

[0057] Specific embodiment two, such as Figure 1 to Figure 5 as shown,

[0058] The construction method of the sliding formwork operation platform of the double-walled concrete silo, first, the inner cone of the silo is constructed to the bottom of the inner wall, and then the pre-installed outer wall sliding formwork is lifted to +22.0m, and the inner The bottom of the cylinder wall is flush, remove the original central steel ring and tie reinforcement, and then start to assemble the inner cylinder wall lifting system according to the following steps:

[0059] The first step is to install the lifting frame of the inner cylinder wall. The jacks of all the lifting frames are at the same level and fixed with vertical and horizontal rods. The spacing between the opening frames is 1200mm-1300mm. Appropriate adjustments;

[0060] The second step is to install the inner and outer purlins of the inner cylinder wall. The installation of the inner and outer purlins needs to consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com