A planning execution control method for excavation path of multi-mode excavation and construction machine

An execution control and multi-mode technology, which is applied in excavation, mechanically driven excavators/dredgers, construction, etc., can solve problems that cannot satisfy construction adaptability and efficiency, and cannot provide switching path planning and execution control technology , to achieve the effect of improving execution efficiency and reliability, reducing labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The core of the present invention is to provide a planning and execution control method for the excavation path of a multi-mode excavation and construction machine. The excavation path is planned by establishing a forward kinematics model and a rock mass space model, and different digging heads are replaced according to different rock mass types. Improve automation and work efficiency.

[0047] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

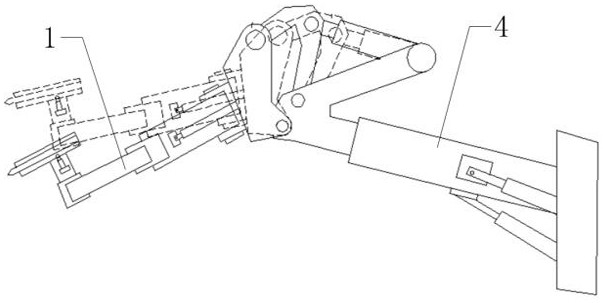

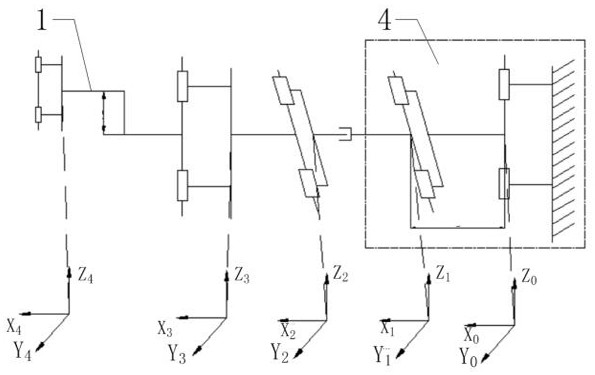

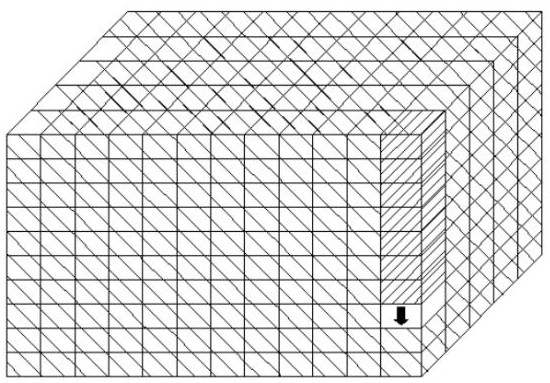

[0048] Please refer to Figure 1 to Figure 9 , figure 1 A structural schematic diagram of the drilling and splitting head in a specific implementation of the planning execution control method provided by the present invention; figure 2 A schematic diagram of the forward kinematics model of the drilling and splitting head in a specific impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com