Control method for frequency conversion regulation of causticizing green liquor system

A control method and causticizing green liquor technology, applied in the field of frequency conversion regulation, can solve problems such as difficult control of the liquid level of the green liquor tank, easy fouling of the green liquor transportation pipeline, and difficulty in adjusting the opening of the valve, so as to achieve high energy saving and high adjustment speed Sensitive, large starting torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, and these examples belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

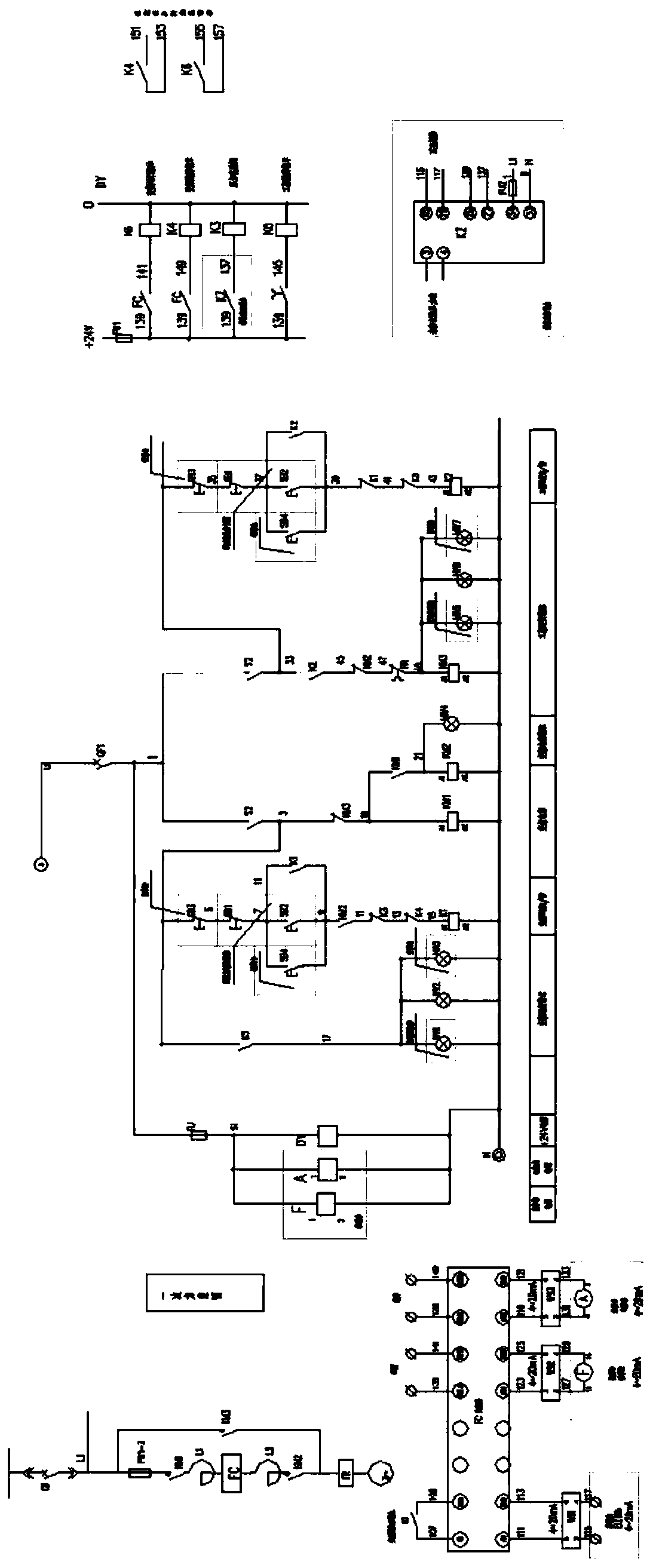

[0034] Such as figure 1 As shown, a control method for frequency conversion regulation of causticizing green liquor system includes the following steps:

[0035] (1) Centralized control: remote control by the console;

[0036] (2) Machine side control: start and stop the motor on the motor field control box;

[0037] (3) The frequency conversion cabinet can input and output the following signals:

[0038] 1) Input signal of switching value of frequency conversion cabinet: drive by frequency converter, that is, passive contact, start when closed, stop when open;

[0039] 2) Frequency conversion cabinet speed given signal: 4~20mADC, speed given signal;

[0040] 3) The frequency conversion cabinet should at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com