Flocculation clarification sewage treatment equipment for sewage treatment

A sewage treatment equipment, sewage treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems to achieve the effect of speeding up the processing rate, saving waiting time, and rapid precipitation processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

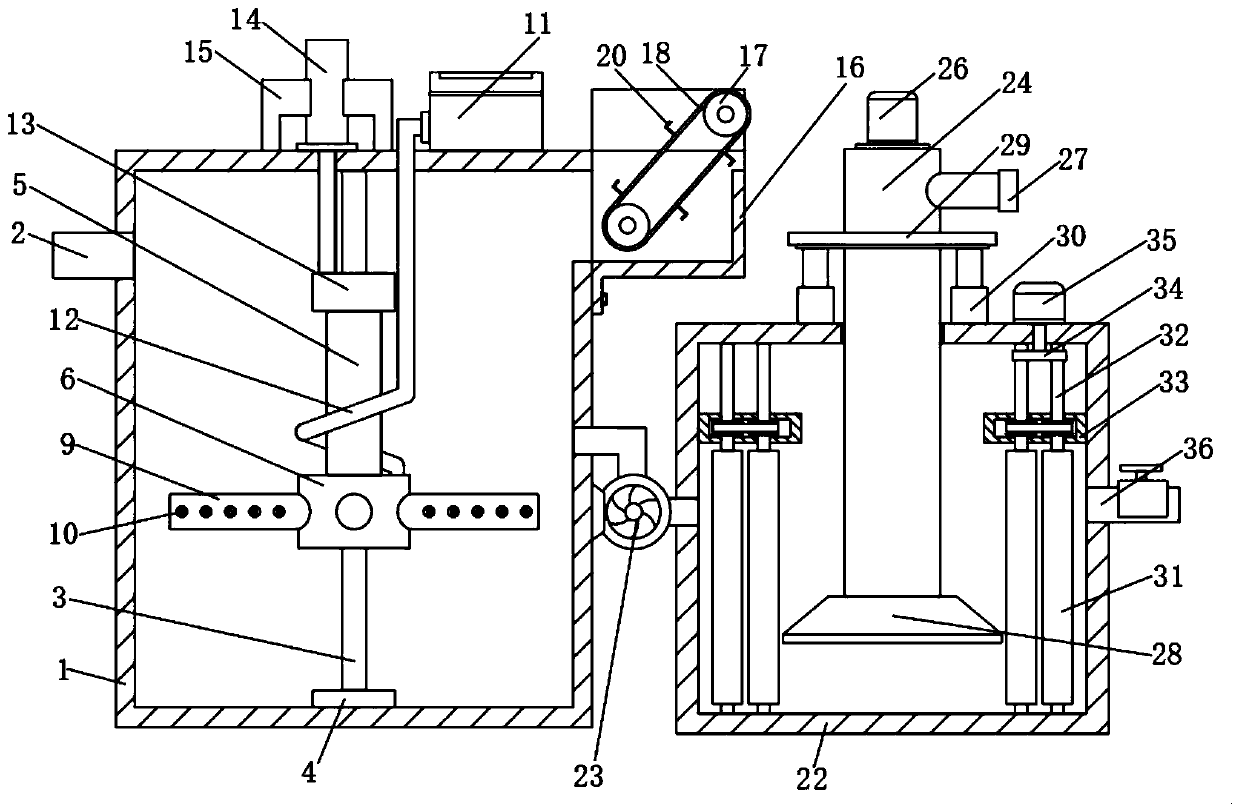

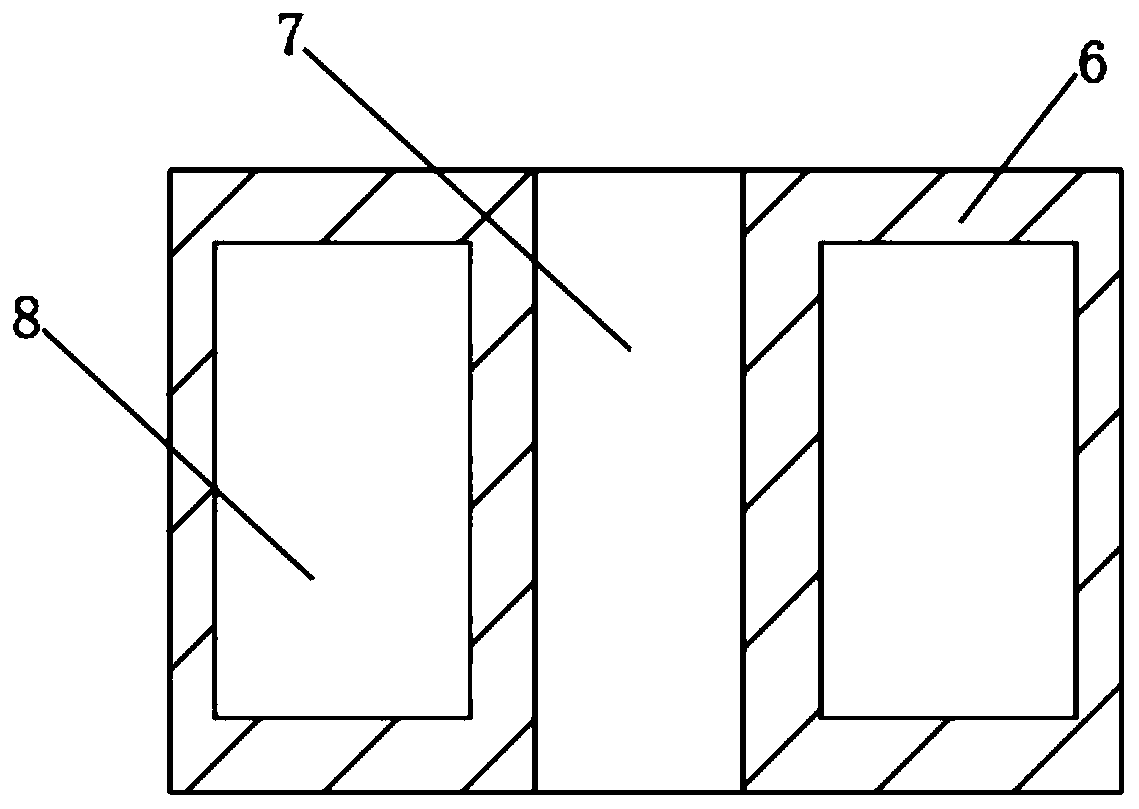

[0027] see Figure 1-5 , a flocculation clarification sewage treatment equipment for sewage treatment, comprising a flocculation box 1 and a sedimentation box 22, the side wall of the flocculation box 1 is fixedly connected with a water inlet pipe 2, the middle part of the flocculation box 1 is fixedly connected with a fixed column 3, and the side of the fixed column 3 The wall is slidably connected with a fitting cylinder 5, and the bottom end of the fitting cylinder 5 is fixedly connected with a sliding ring 6. The inner side of the sliding ring 6 is provided with a ventilation groove 8, and the side wall of the sliding ring 6 is fixedly connected with several fixing cylinders 9, and the fixing cylinder 9 is connected with the ventilation groove. The grooves 8 are connected, and the side wall of the fixed cylinder 9 is provided with several exhaust holes 10. The air generator 11 is fixedly installed on one side of the top of the flocculation box 1, and the air delivery pipe 1...

Embodiment 2

[0030] see Figure 1-5 , made further improvements on the basis of Example 1: the middle part of the bottom end of the flocculation box 1 is fixedly connected with the support plate 4, and the bottom end of the fixed column 3 is fixedly connected with the top middle part of the support plate 4; the inner side of the sliding ring 6 is provided with a sliding groove 7 , and the sliding groove 7 is matched and slidably connected to the side wall of the fixed column 3; the top of the flocculation box 1 is fixedly connected with a stabilizer 15, and the stabilizer 15 is located on the side wall of the first hydraulic cylinder 14; , The side wall of the drain pipe 36 is fixedly equipped with a valve.

[0031] In this embodiment, the support plate 4 can ensure that the fixed column 3 has better strength in use, which is convenient for the sliding performance of the sliding ring 6 on the side wall of the fixed column 3, and the use of the stabilizer 15 can ensure that the first hydrau...

Embodiment 3

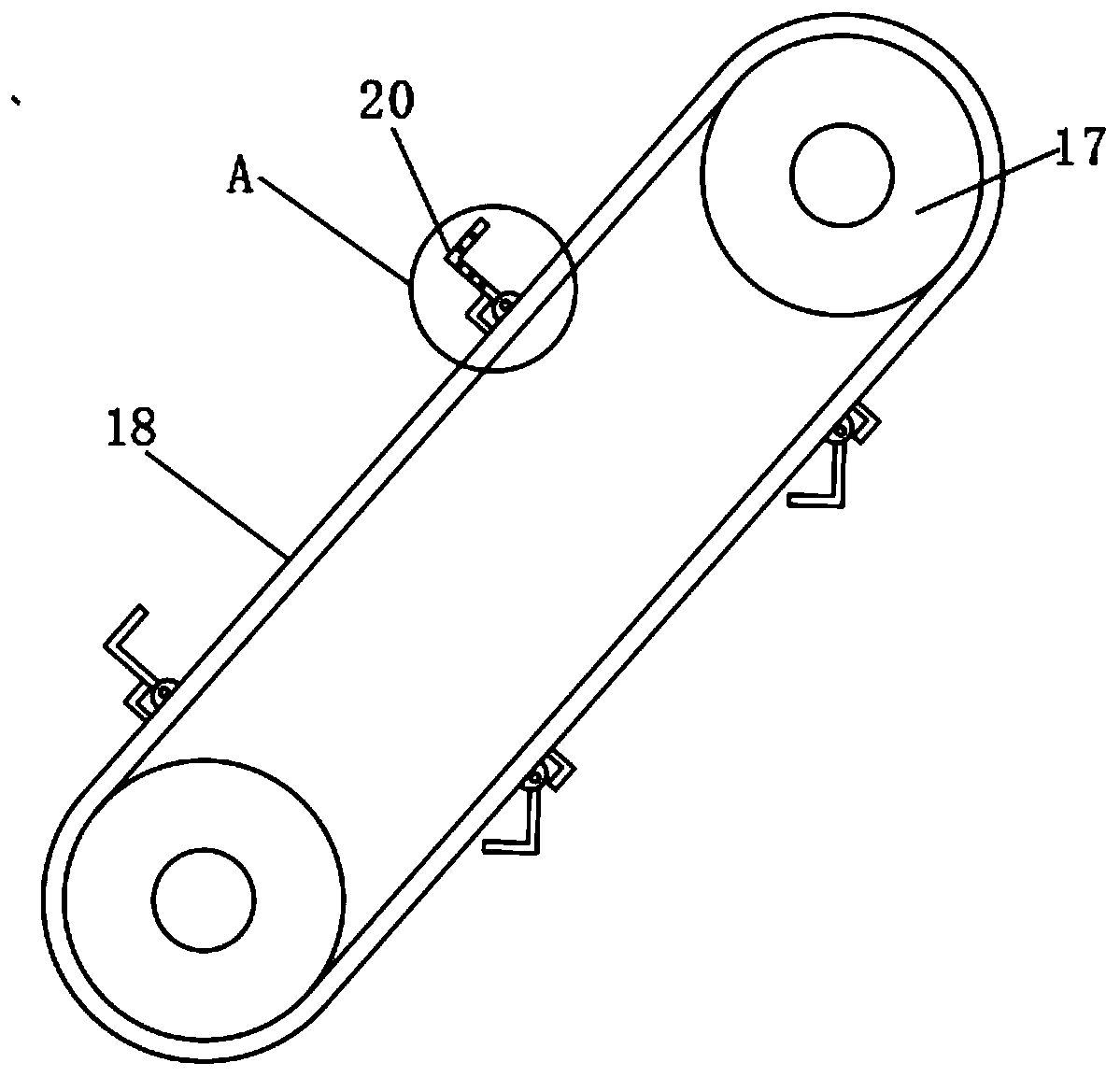

[0033] see Figure 1-5 On the basis of Example 1, a further improvement has been made: one side of the flocculation box 1 is fixedly connected with a connecting box 16, and two turning rollers 17 are rotatably connected in the connecting box 16, and the side walls of the two turning rollers 17 are fixedly connected with rotating Belt 18, the side wall of rotating belt 18 is fixedly connected with fixing part 19, and the fixing part 19 is connected with filter plate 20 in rotation; at one end of the filter plate 20.

[0034] In this embodiment, the rotating roller 17 is driven by an external motor to rotate, and then the rotating roller 17 drives the rotating belt 18 to rotate. During the rotation of the rotating belt 18, the filter plate 20 can be driven to move, and then the filter plate 20 is used to filter the suspended matter. Filtration is carried out, and then during the rotation of the rotating roller 17, the filter plate 20 swings under the action of gravity, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com