Aerobic sludge rapid granulation equipment and treatment process thereof

An aerobic sludge and treatment process technology, which is applied in aerobic process treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. Insufficient effect and other problems, to achieve the effect of convenient and stable use, high degree of automation, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

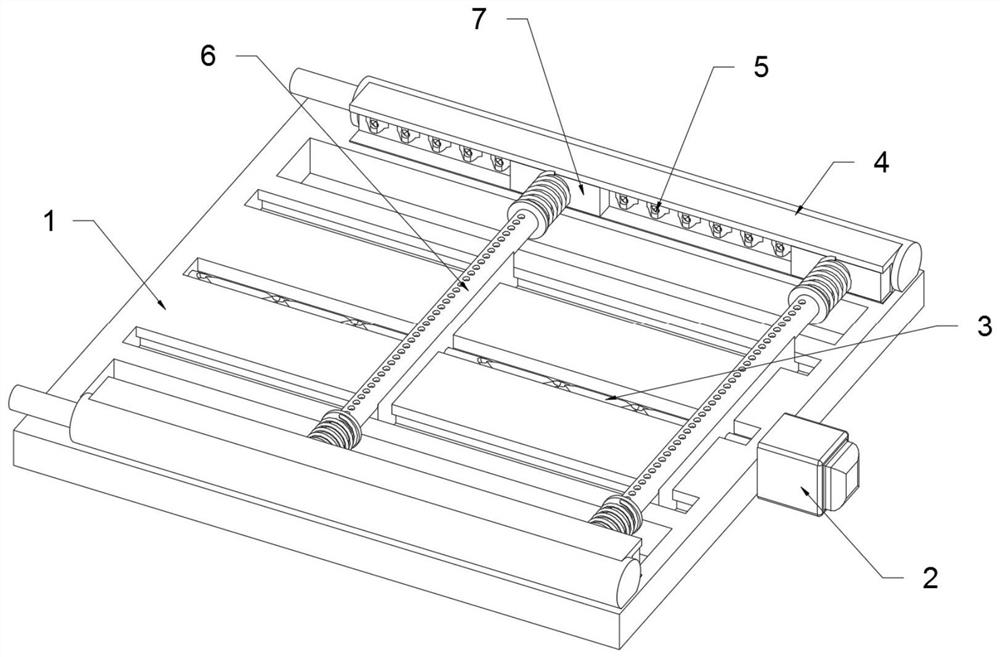

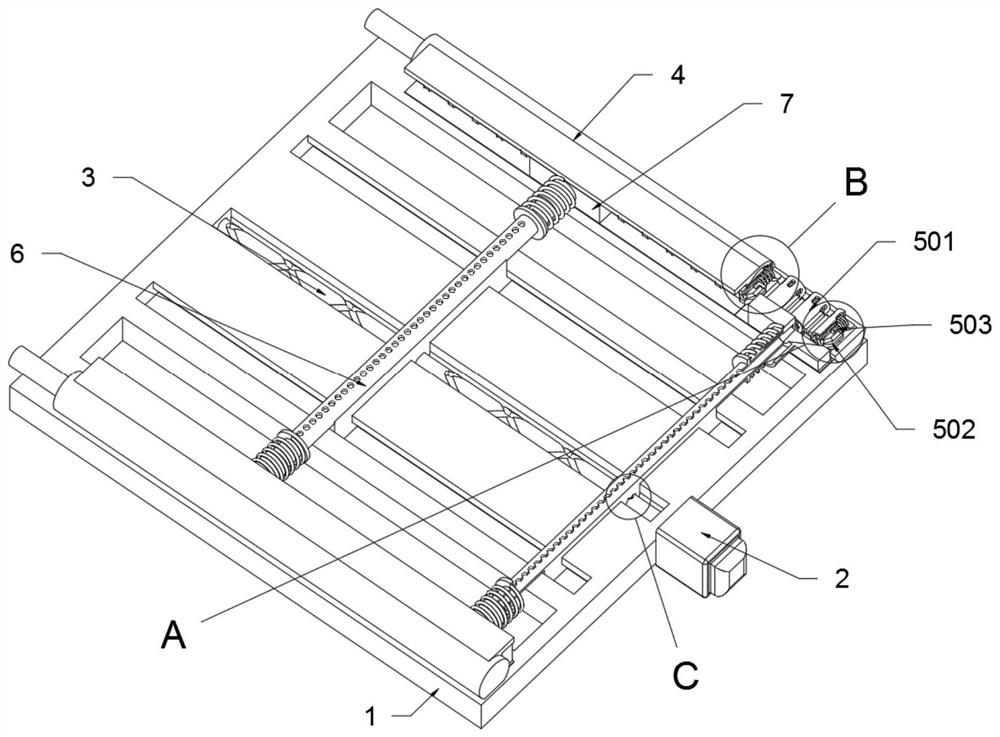

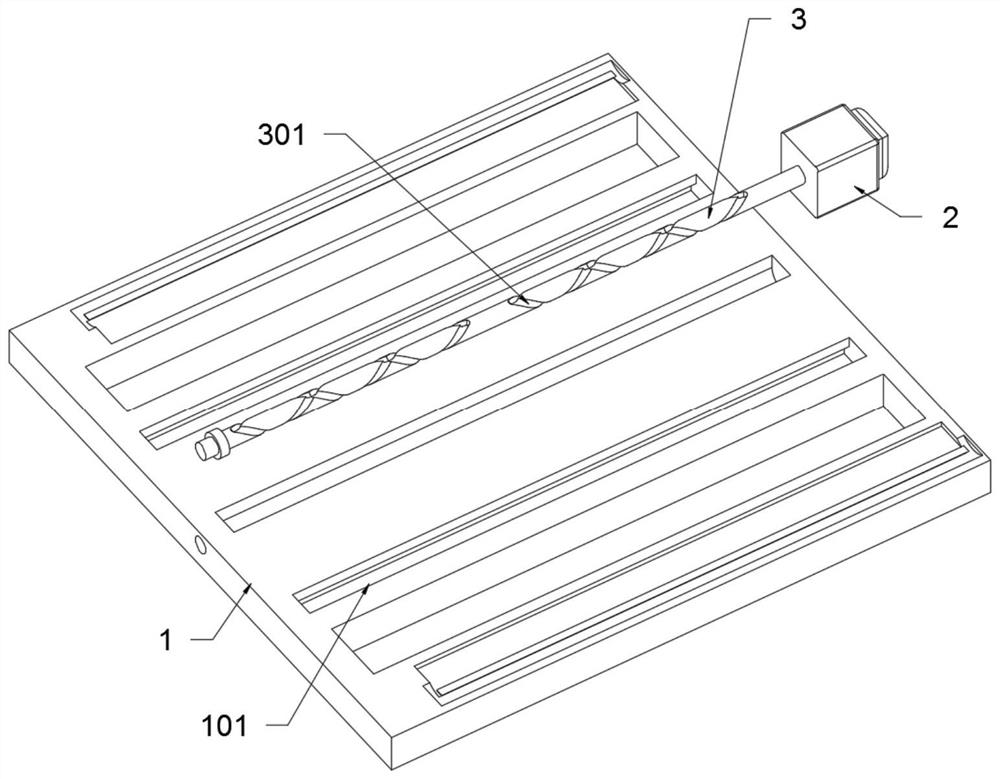

[0034] Example: please refer to Figure 1 to Figure 9 :

[0035] The present invention proposes an aerobic sludge rapid granulation equipment and a treatment process thereof, comprising: installing a chassis 1 and a driving rod 3 ; a driving motor 2 is fixedly installed on the side of the installation chassis 1 , and the top of the chassis 1 is installed The air supply assembly and the follower assembly are installed; the driving rod 3 is rotatably connected to the inside of the installation chassis 1, and one end of the driving rod 3 is connected with the rotating shaft of the driving motor 2 in a driving manner; the air supply assembly includes an adapting air pipe 4 and an adapting mechanism 5 , the adapting air pipe 4 is fixedly installed on the top of the installation chassis 1; the adapting mechanism 5 includes a positioning shell 501, an adapting air column 502 and a control swivel 503, the positioning shell 501 is fixedly installed inside the adapting air pipe 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com